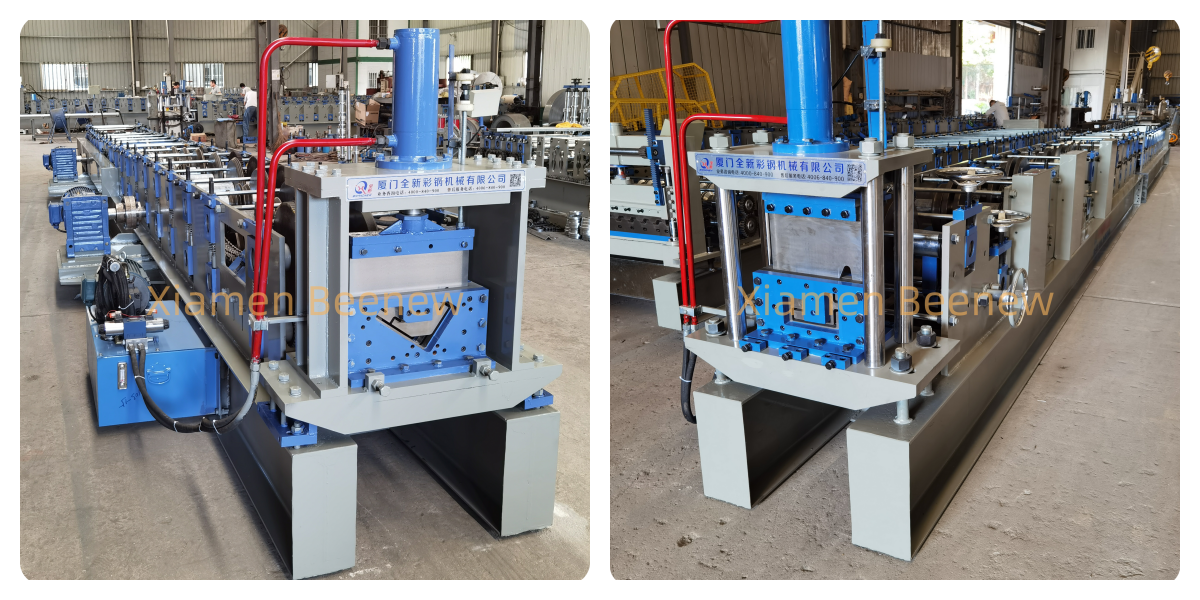

Efficient Packaging Room Box Roll Forming Machine for High-Quality Custom House

Machine Parameters

| Item | Value |

| Driving Motor | 15KW*2 |

| Forming Station | 20 |

| Roller Material | GCr15 |

| Shaft Diameter | 75/95mm |

| Shaft Material | 45# steel |

| Pump Motor | 7.5KW |

| Frame Type | Common weld wall |

| Cutting Type | Hydraulic Cutting |

| Control System | PLC |

| Main Electric Parts Brand | Simenz, Delta, Omron or Schneider |

| Cutting Length Precision | ±2mm |

| Machine Dimension | 10500*1150*1450mm |

| Electric Standard | 380V/50HZ/3Ph or customized |

| Paint Color | Grey White+bule or customized |

Key Features

1. High Precision:

– Accuracy: Ensures precise dimensions and shapes, which are crucial for the structural integrity of container houses.

– Consistency: Maintains uniformity across multiple frames, reducing errors and waste.

2. Automation:

– Automated Operation: Minimizes human intervention, leading to faster production times and reduced labor costs.

– Computer Control: Uses PLC (Programmable Logic Controllers) for precise control and customization of the production process.

3. Durable Construction:

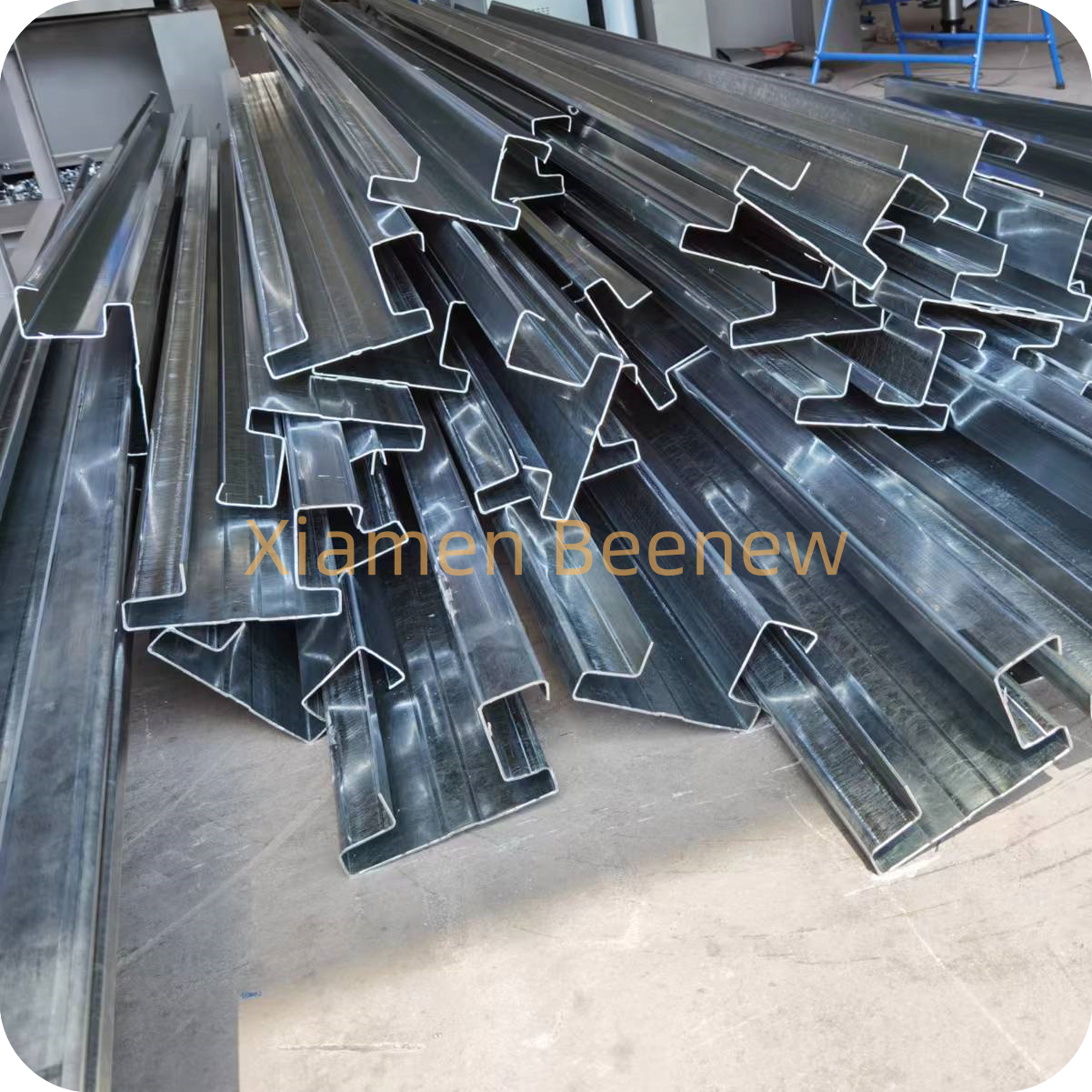

– Heavy-Duty Rollers: Built to handle high-strength steel materials, ensuring the frames can withstand harsh environmental conditions.

– Robust Design: The machine itself is constructed to endure continuous operation and high production demands.

4. Flexibility:

– Customizable Profiles: Capable of producing various frame designs and sizes to meet different architectural requirements.

– Modular Configuration: Allows for easy adjustments and upgrades as needed.

Benefits

1. Cost-Effective:

– Reduced Labor Costs: Automation decreases the need for extensive manual labor.

– Material Efficiency: Precise cutting and shaping minimize material waste.

2. Time-Saving:

– Rapid Production: Significantly cuts down the time needed to produce container house frames compared to traditional methods.

– On-Demand Manufacturing: Enables quick response to market demands and project timelines.

3. Quality Assurance:

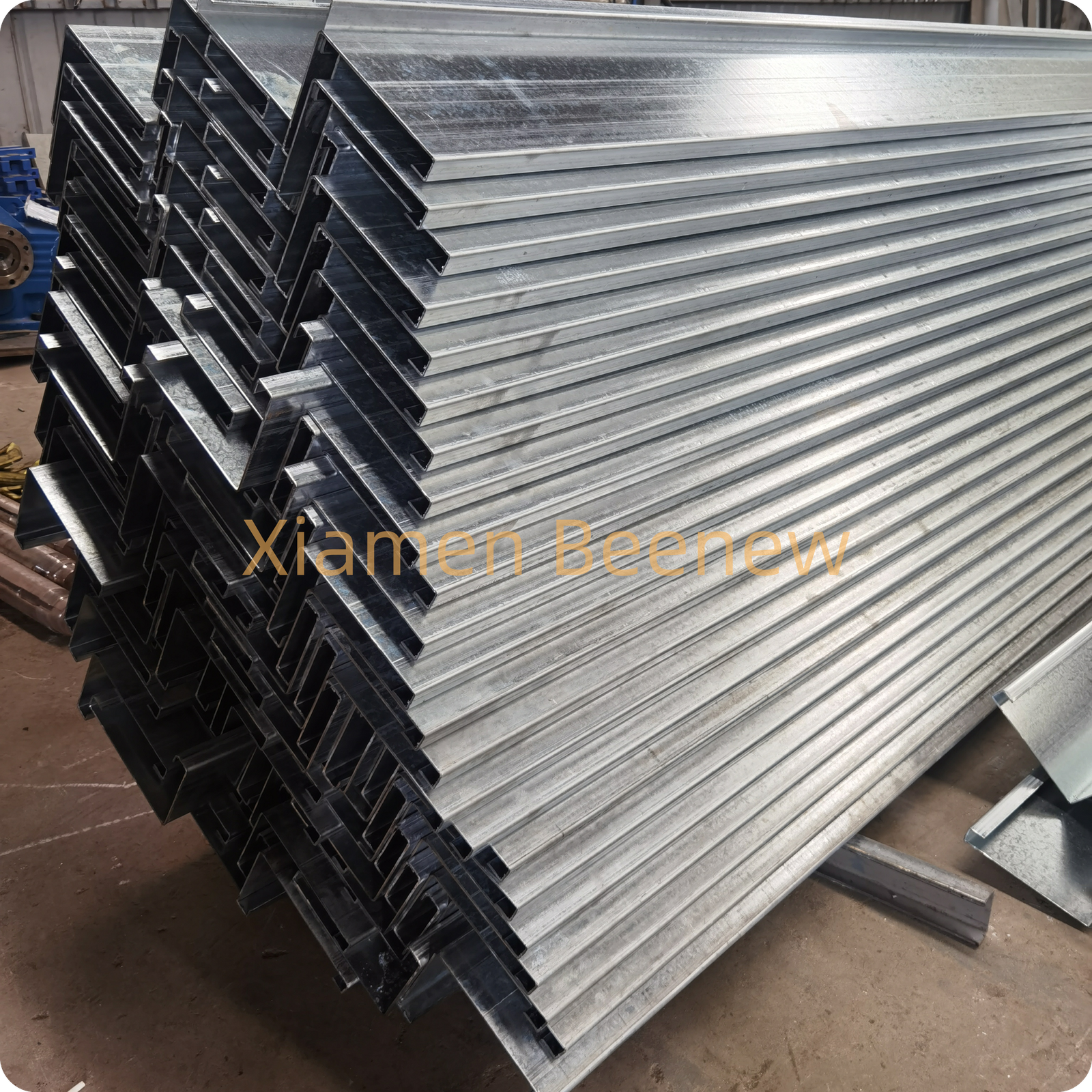

– High-Quality Output: Consistent and precise frames contribute to the overall quality of the container houses.

– Durability: Ensures the produced frames meet high standards for longevity and resilience.

4. Scalability:

– Large-Scale Production: Suitable for mass production, supporting large construction projects.

– Small Batch Flexibility: Also efficient for smaller production runs, offering flexibility for custom projects.

Applications

– Residential Construction: Producing frames for container homes used in various residential projects.

– Commercial Buildings: Manufacturing frames for office spaces, retail outlets, and other commercial structures.

– Emergency Shelters: Rapid production of frames for emergency housing in disaster relief situations.

– Modular Buildings: Frames for modular construction projects that require quick assembly and disassembly.

In summary, a container house frame roll forming machine is essential for efficiently producing high-quality steel frames used in the construction of container houses. Its precision, automation, and flexibility make it a valuable asset in modern construction, catering to both large-scale and custom projects.

Reviews

There are no reviews yet.