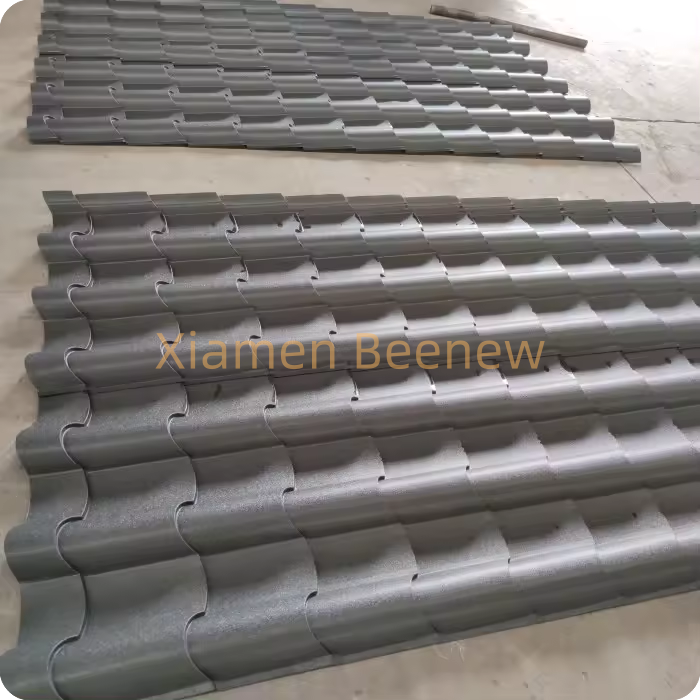

Product Name: Roof Panel Roll Forming Machine

Machine Parameters

| Item | Value |

| Driving Motor | 15KW*2 |

| Forming Station | 20 |

| Roller Material | GCr15 |

| Shaft Diameter | 75/105mm |

| Shaft Material | 45# steel |

| Pump Motor | 7.5KW |

| Frame Type | Common weld wall |

| Cutting Type | Hydraulic Cutting |

| Control System | PLC |

| Main Electric Parts Brand | Simenz, Delta, Omron or Schneider |

| Cutting Length Precision | ±2mm |

| Machine Dimension | 10500*1520*1750mm |

| Electric Standard | 380V/50HZ/3Ph or customized |

| Paint Color | Grey White+bule or customized |

Conclusion

The Roof Panel Roll Forming Machine for Versatile Metal Roof Tile Production is a highly efficient and reliable solution for manufacturers looking to produce high-quality metal roof tiles. Its advanced features, combined with cost-saving benefits and wide-ranging applications, make it an invaluable asset in the roofing industry. Whether for residential, commercial, industrial, or agricultural purposes, this machine ensures that manufacturers can meet diverse demands with precision and efficiency.

Reviews

There are no reviews yet.