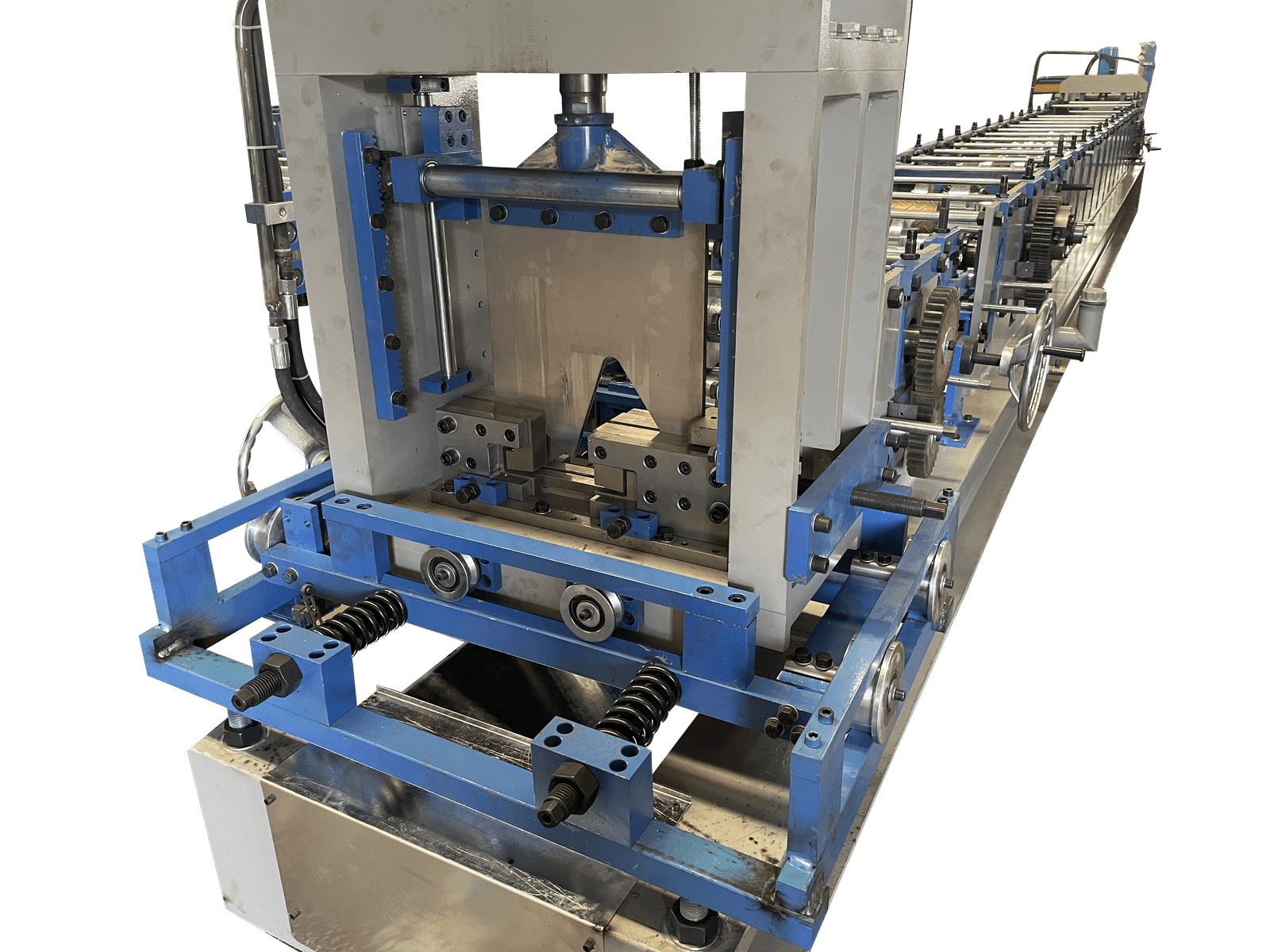

Z Purlin Roll Forming Machine

Beenew Z purlin roll forming machine, often referred to as a galvanized steel Z shape purlin roll former, is a specialized piece of equipment designed for the manufacturing of Z type steel.

The Z shape purlin steel fabricated by this machine boasts excellent bending resistance capabilities, ensuring its structural integrity under various loads. It also features remarkable straightness, which is crucial for applications where precise alignment and dimensional accuracy are required. Additionally, one of the notable advantages of this type of purlin steel is its ability to undergo online punching and cutting operations. This not only streamlines the production process but also enhances efficiency by eliminating the need for additional, separate machining steps.

Machine Components

Hydraulic Uncoiler

1)Hydraulic expanding

2)Motorized decoil

Flattening & Guiding System

1) Top 4 and bottom 5 solid shaft

2) Including guiding shaft and guiding rollers, width is adjustable for various steel strips

3) Shaft material undergoes CNC machining, followed by quenching and tempering heat treatment. Afterward, the shaft is finish turned, polished, and then chrome plated.

Main Roll Forming Machine

1)21 main stations

2)Chain + gear/ sprocket transmission

3)Machine base welded by H450 plate, with shot blasting and heat treatment

4) Cr12 roller, CNC-machined, heat-treated, finished with turning, polishing, & chrome plating, achieving HRC 58-60 hardness

5) Main shaft round steel, quenched & tempered

6)Main motor 30kw servo main motor

7)Size change fully automatic by PLC

Hydraulic Punching

1)Adopt post-punch, automatic punch to set parameters.

2)Punching device,3 groups (double holes + double holes + single hole) 14*25

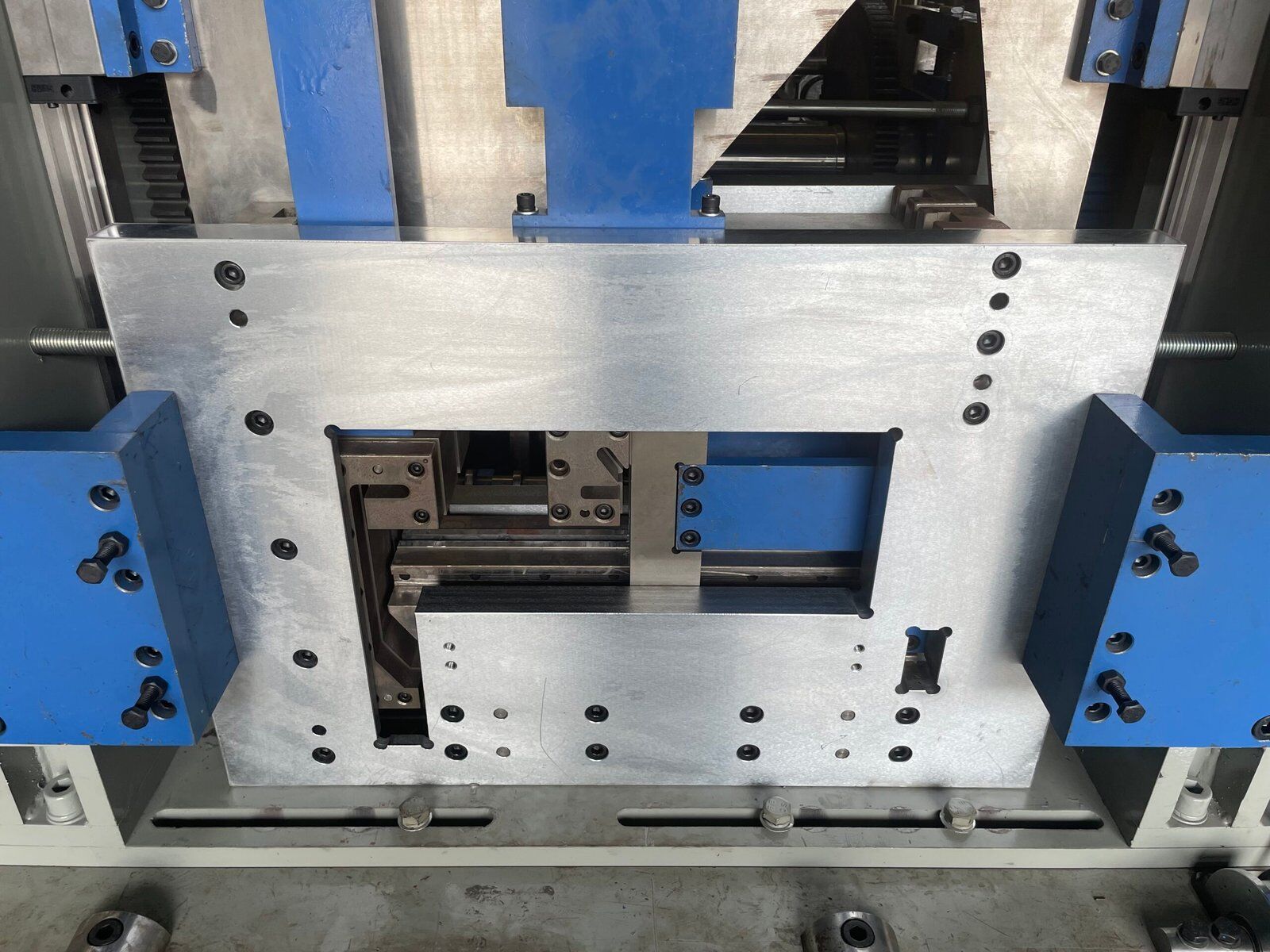

Post-Cutter

1)Adopt post cut, automatic cut to length&quantity, etc

2)Cutter Cr12Mov die steel heat treatment after wire cutting

Power Supply & Control System

1)Control cabinet 1 set with ’emergency stop’ switch

2)Control handle 1 set for jogging during machine testing & production phases

3)Operational platform featuring HMI & buttons, displaying in English language

Product rack

1) 2 sets, 3 meters each, free roller type

Video

Reviews

There are no reviews yet.