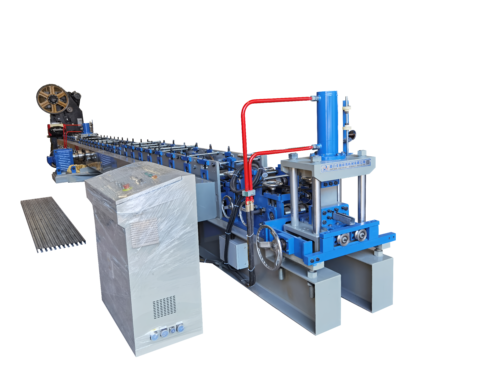

CZ Purlin Roll Rorming Machine

CZ Purlin Roll Forming Machine: Features & Advantages

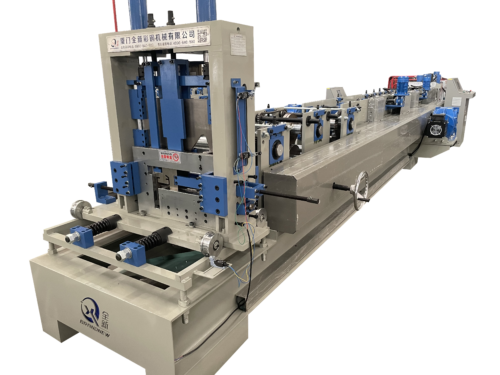

Model Highlight: CZ30030

A premium solution tailored for mid-to-high-end markets, combining exceptional stability, precision, and versatility.

Roll Forming Stations: 20 stations with double straightening technology for ±0.5mm accuracy.

Material Range:

Width: 80–300mm

Thickness: 1.0–3.0mm

Output Efficiency: Fast production speeds (up to 12m/min) with consistent power stability.

Series Innovation: 300 Series

Redefines industry standards with expanded capabilities for diverse project demands.Multiple configurations available to adapt to specific production environments.

Core Strengths:

Durability: Robust Cr12MoV steel components extend machine lifespan.

Precision Engineering: High-accuracy forming and cutting for flawless purlin profiles.

Ease of Use: Automated adjustments (e.g., web size switching in 5 minutes) minimize downtime.

Customization: Modular design supports tailored solutions for unique client requirements.

Why Invest in CZ30030 CZ purlin roll forming machine?

Ideal for SMEs and large manufacturers alike, this machine ensures cost-effective production while maintaining premium quality. The 300 series unlocks limitless potential in roofing, steel structures, and industrial applications.

| Machine Quick Details | |

| Model number: CZ30030 | Condition: New |

| Type: CZ Purlin machine | Brand Name: Beenew |

| Max Production Capacity: 30m/min | Power(W): 22KW |

| Warranty: 2 years | Place of Origin: China |

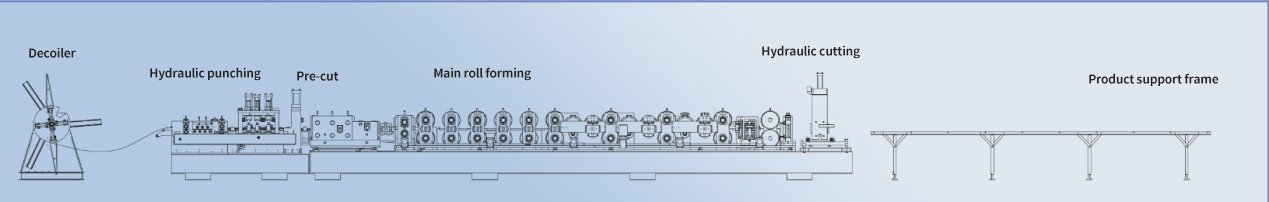

Work Flow

Decoiler – Leveling device — pre- punching and pre-cutting – roll forming line – Product rack

Video

The Advantages of CZ purlin roll forming machine

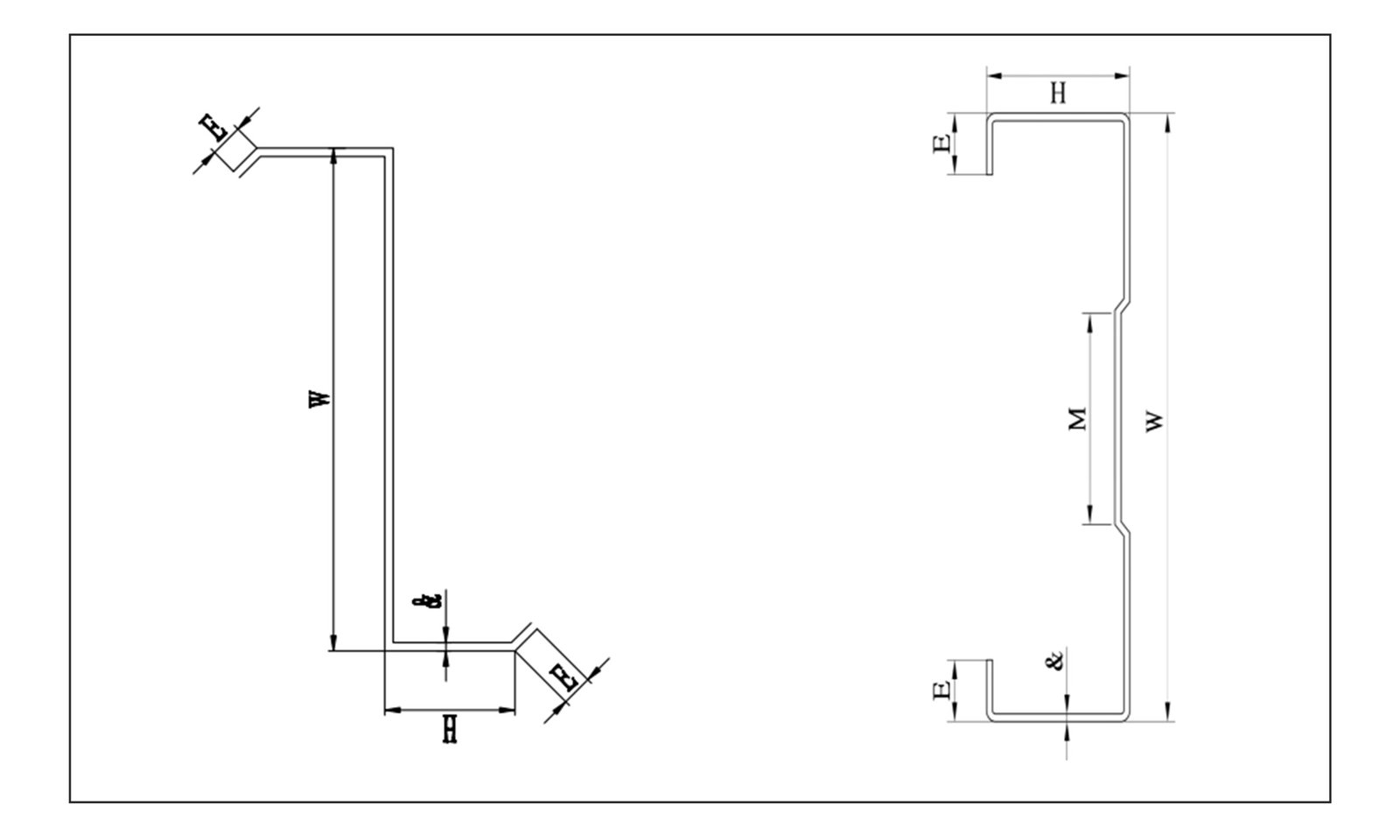

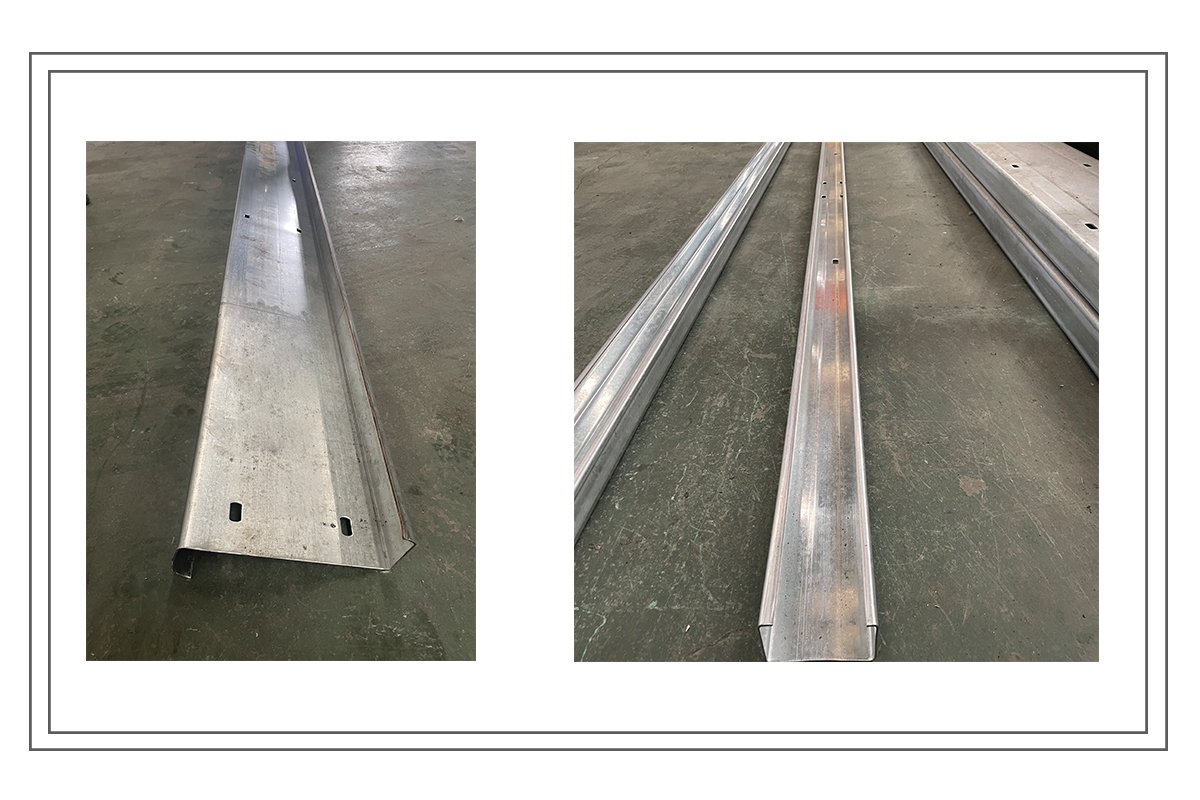

1. Versatile Sizing Capability: It is capable of manufacturing purlins in a diverse range of sizes. For C purlins, it can produce sizes from C80 to C300, and for Z purlins, from Z120 to Z300.

2. Consistent Cutting Mechanism: The machine eliminates the hassle of changing the cutter when dealing with different purlin sizes.

3. User-friendly and Economical: The operation of the CZ purlin roll forming machine is straightforward, making it accessible even for operators with relatively little experience.

4. Material-saving Infinite Sizing: With its infinite sizing feature, the machine can produce purlins of any size within its specified range.

5. Flexible Punching Options: An optional feature of the machine is the ability to punch holes at any position on both the web side and the flange side of the purlin.

Main Components

1. Hydraulic Decoiler

Un-coiler Type: Automatic fasten and loosen

Weight capacity: 5T

2. Feeding and Leveling Device:

This device serves the purpose of flattening the material.

3. Pre – punching Apparatus

Perform punching on flat sheets. The PLC manages the punch quantity and horizontal location, while the vertical location is manually adjustable.

Web punching quantity & dimensions: customized according to customer needs

Flange punching quantity & dimensions: customized according to customer needs

The punching bar and punching die are easy to replace

4. Pre – cutting Equipment

It is applied to cut raw materials prior to roll forming.

5.Main Roll Forming M/C

Drive Type: Chain – driven

Maximum Forming Speed: 30m/min

Rollers: Approximately 20 sets of rollers

Roller Material: Cr15 die steel;

Lower Roller Diameter: Around 360mm

Shaft: The shafts of the rollers are ground twice by a grinding machine to guarantee the precision of the final product. Main shaft diameter: ø95mm (subject to the final design)

Main Shaft Material: 40Cr

Size Change: Fully – automatic

Equipped with a fast C/Z interchange system

Fast C/Z interchange achievable in just 3 steps, within 5 – 15 minutes.

6. Hydraulic Cutting

Our innovative cutting system uses CZ integrated & adjustable molds. No need to change molds for different purlin sizes.

7.Product track —1 set

8. PLC Control System

Automated Control: Manages production quantity, punching length, and cutting length with precision.

Operational Safety: The machine is automatically paused during punching and cutting processes.

Measurement & Counting:

Automatic length measurement (precision: ±2mm).

Real-time production quantity tracking.

9.Product-CZ purlin

Our factory

Why Choose us:

– Boasting 28 years of expertise in manufacturing CZ purlin roll formers.

– Offering products with competitive prices and high – quality standards.

– Providing a 2 – year complimentary warranty.

– Ensuring a rapid response in after – sales service.

– Capable of automatically adjusting web size from 100mm to 300mm within 5 minutes.

– Open to customization according to clients’ specific needs.

– Featuring user – friendly operation and straightforward maintenance.

– Having self – developed post cutters, where a single blade can cut all sizes of final products.

Reviews

There are no reviews yet.