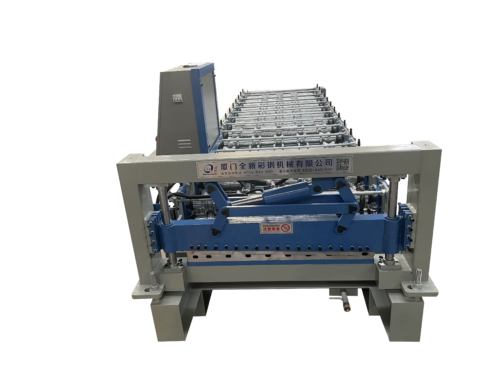

Corrugated Roof Tile Making Machine

We Xiamen Beenew Machinery, as a leading manufacturer in roofing roll forming machine technology, we proudly present our Corrugated Roof Tile Making Machine for high-speed, continuous roll forming and pressing of durable corrugated roof tile sheets. Designed for versatility, this machine’s profile length and step tile depth are adjustable, with a production speed of 4-7m/min, our equipment delivers exceptional efficiency without compromising on quality.

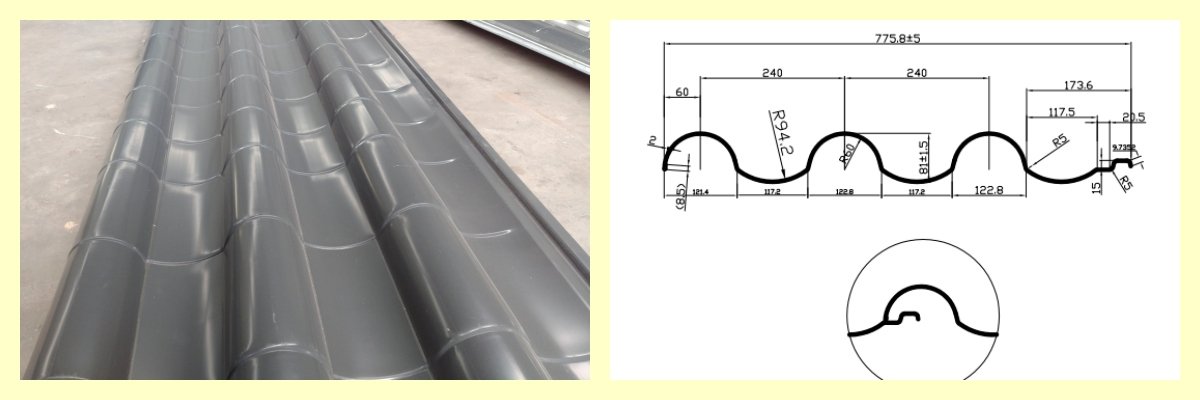

Profile Design & Sample Pictures

Machine Key Features

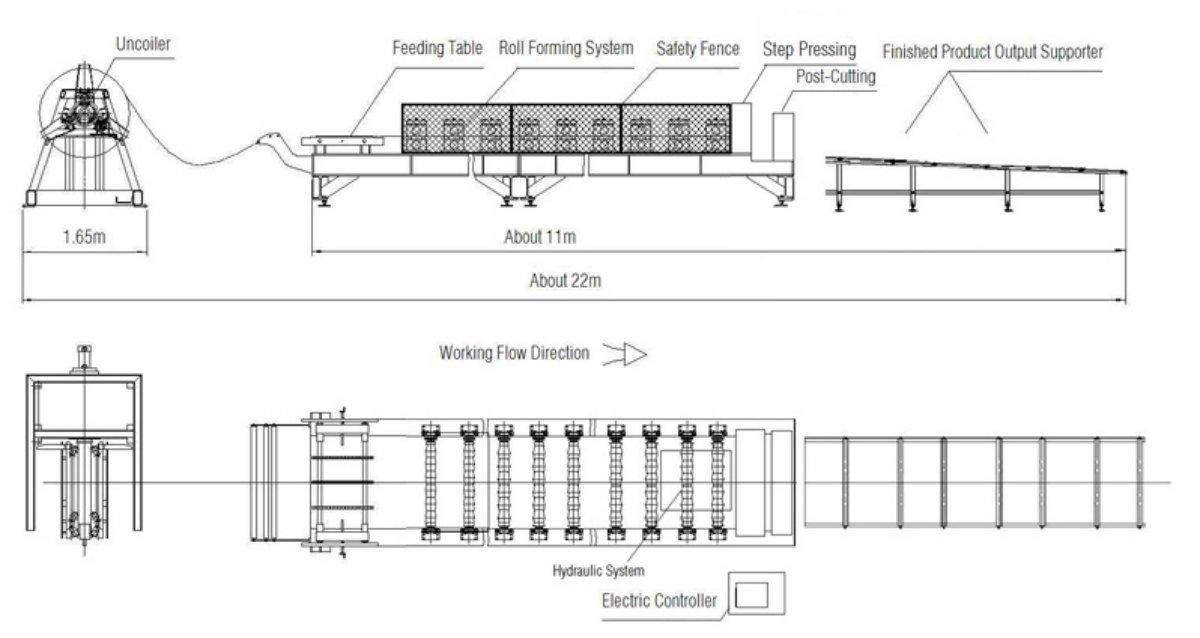

5Ton*1250mm Hydraulic un-coiler

Hydraulic system to expand coil inner hole;hydraulic motor: 2.2KW;

Coil Inner-diameter=470-540mm. Coil Outer-diameter Max. 1300mm

Load Capacity: Max.5Tons; Coil Width Max. 1250mm

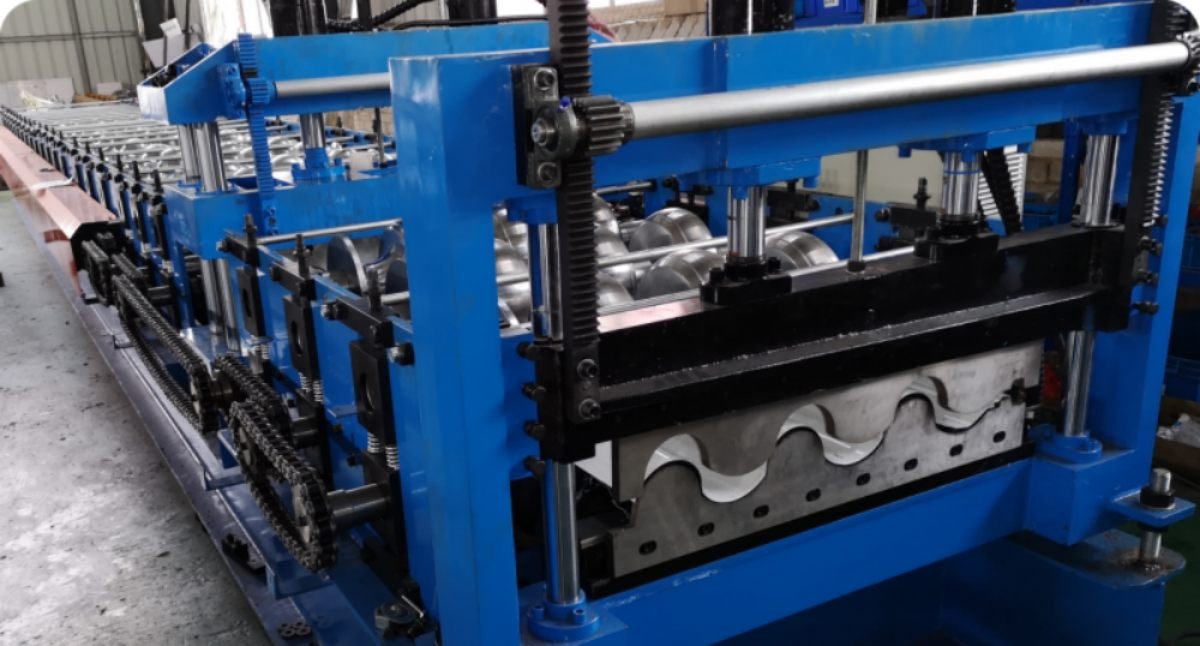

Cold Rolling Machine

Feeding section with guide

Gear/Sprocket driving;16-step to form;

Rollers manufactured from 45 # steel, CNC lathes, hard Chrome Coated

Shafts Diameter=ф75mm, Precision Machined

Main motor =7.5 KW, Frequency speed control

Forming speed:Approx. 4-6 m/min

Hydraulic Stair-Drawing & Cutting M/C

Stair depth=14mm

Pump motor =5.5KW; Cutting pressure=Max.12Mpa

Cutting tool material: Cr12, Heat treatment

PLC Control System

Control the tile length & quantity & cutting length automatically.

Tile length: 200-400mm

Combined with:PLC, inverter, Touch Screen, Encoder, etc

Cut-to-length tolerance≤±2 mm

Control voltage 24V

Producing Line Flow Chart

Key Features:

– Adjustable Tile Depth Design: Tailor wave depth and profile dimensions for unique project demands.

– High-Speed Performance: Optimized for productivity with minimal downtime.

– Certified Durability: Built with premium materials for long-term operation.

– Intuitive Controls: Simplified interface for hassle-free adjustments.

– Safety-Centric Engineering: Integrated safeguards to protect operators and equipment.

Machine Details

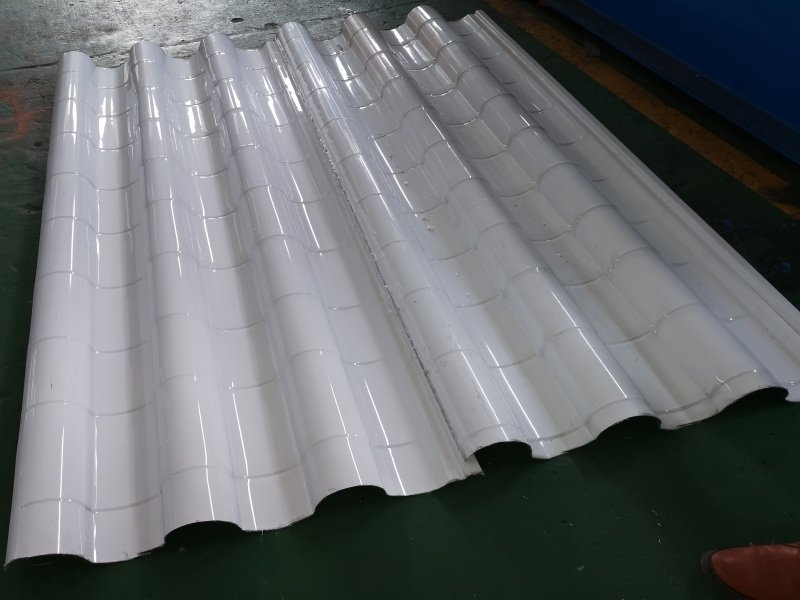

The high-speed roofing tile roll forming machine is for continuously roll forming and pressing step tiles sheets. The step length of this series can be set up and the depth of each step is adjustable. It’s production speed of this series is about 3-6m/min. Similar to other roof sheet roll forming machines, this high-speed metal roof tile equipment is also certified with multiple patents. In addition, prompt delivery is also available.

As a Corrugated Roof Tile Making Machine factory, we specialize in the production of high-quality tile machine for sale that are designed to meet the needs of both commercial and residential customers. Our wholesale roof tile machine is easy to use, offer excellent performance, and is highly durable. As one of the leading roof tile machine manufacturers, we pride ourselves on providing our customers with the highest quality products and services available in the industry.

Steel Tile Roof Application in Engineer

Reviews

There are no reviews yet.