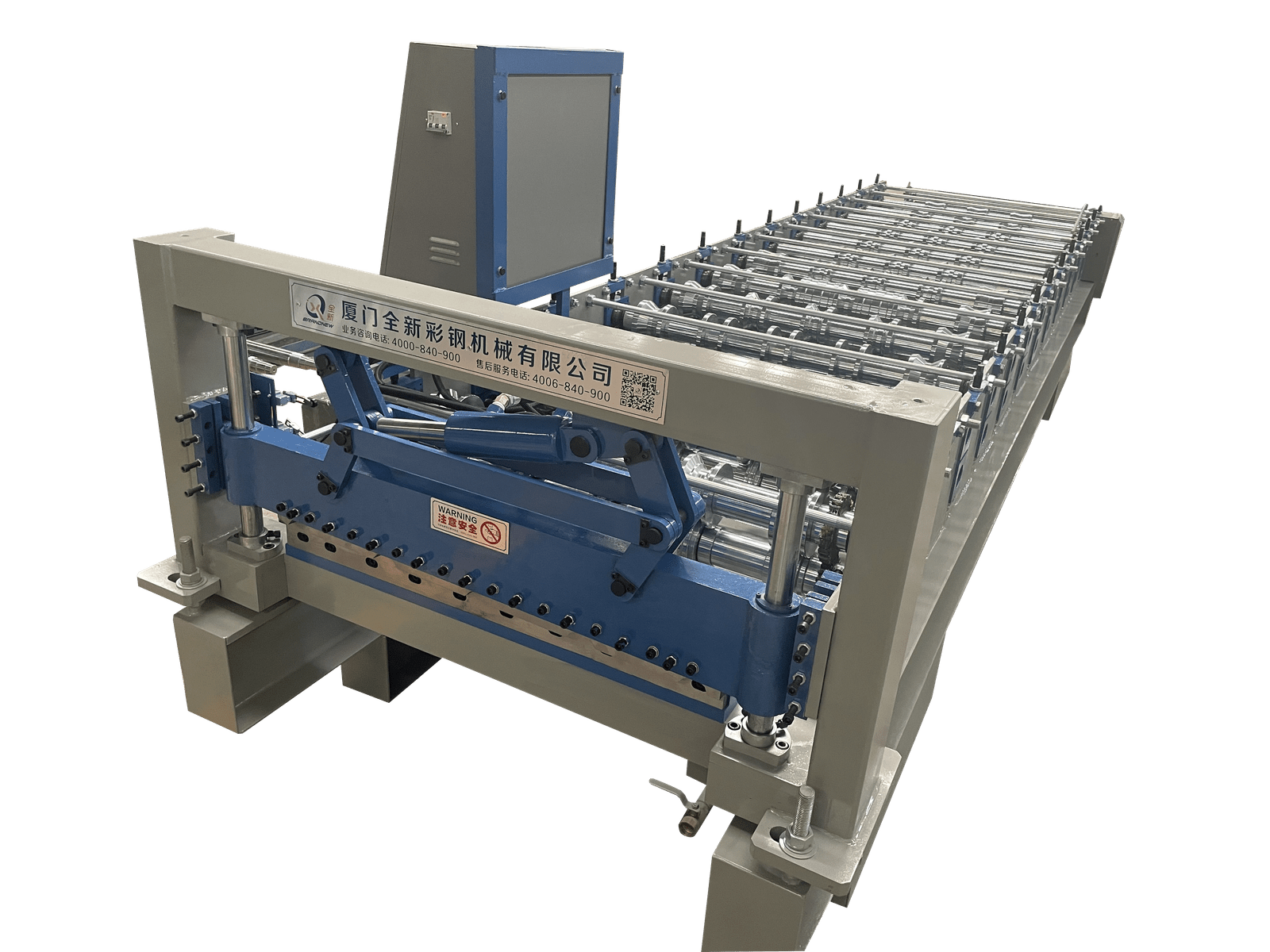

R panel roll forming machine

As the name implies, this series specializes in manufacturing R panels – a widely used metal siding and roofing solution for commercial steel-framed buildings. Beenew machinery ensures rigorous quality control throughout the production process, delivering premium-grade R panel roll forming machines with customizable specifications at competitive prices.

Key Features:

Designed for high-efficiency R panel production.

Versatile specifications to meet diverse project needs.

Cost-effective pricing without compromising durability.

For detailed technical specifications or inquiries about our siding panel machinery, please contact us directly. We’re available to assist you at any time.

Features & Advantages of R Panel Roll Former

Versatile Application: Specifically engineered for high-volume production of roofing sheets, siding panels, and floor decking.

High-Speed Performance: Adjustable production speeds of 20–30 m/min, with a maximum line speed of 30 m/min.

Multi-Profile Flexibility: Equipped with a cassette-style platform for rapid tooling changes, enabling seamless switching between profiles.

Certified Quality: Compliant with CE standards and European quality benchmarks, backed by multi-patent certifications.

Ready Stock Availability: Popular R panel machine models are kept in stock for fast delivery, minimizing project lead times.

Ideal for commercial and industrial projects, our R Panel Roll Former combines innovation, efficiency, and reliability. Contact us for tailored solutions!

Suitable Raw Material for R Panel Roll Former

Material Type: Color-coated steel, Galvanized steel, Aluminum sheet, Stainless steel

Thickness: 0.3–0.6 (mm)

Yield Strength: 230–300 / 350 / 550–675 (MPa, optional)

Width: 1038, 1055, 1092 (mm)

Components and Parameters

Production Line Components and Parameters of r panel roll former

| No. | Content | Description |

| 1 | Decoiler | 5t/8t/10t/15t Motor/hydraulic motor/passive(optional) |

| 2 | Filming covering device | optional |

| 3 | Front shear | optional |

| 4 | Lubricating device | no need |

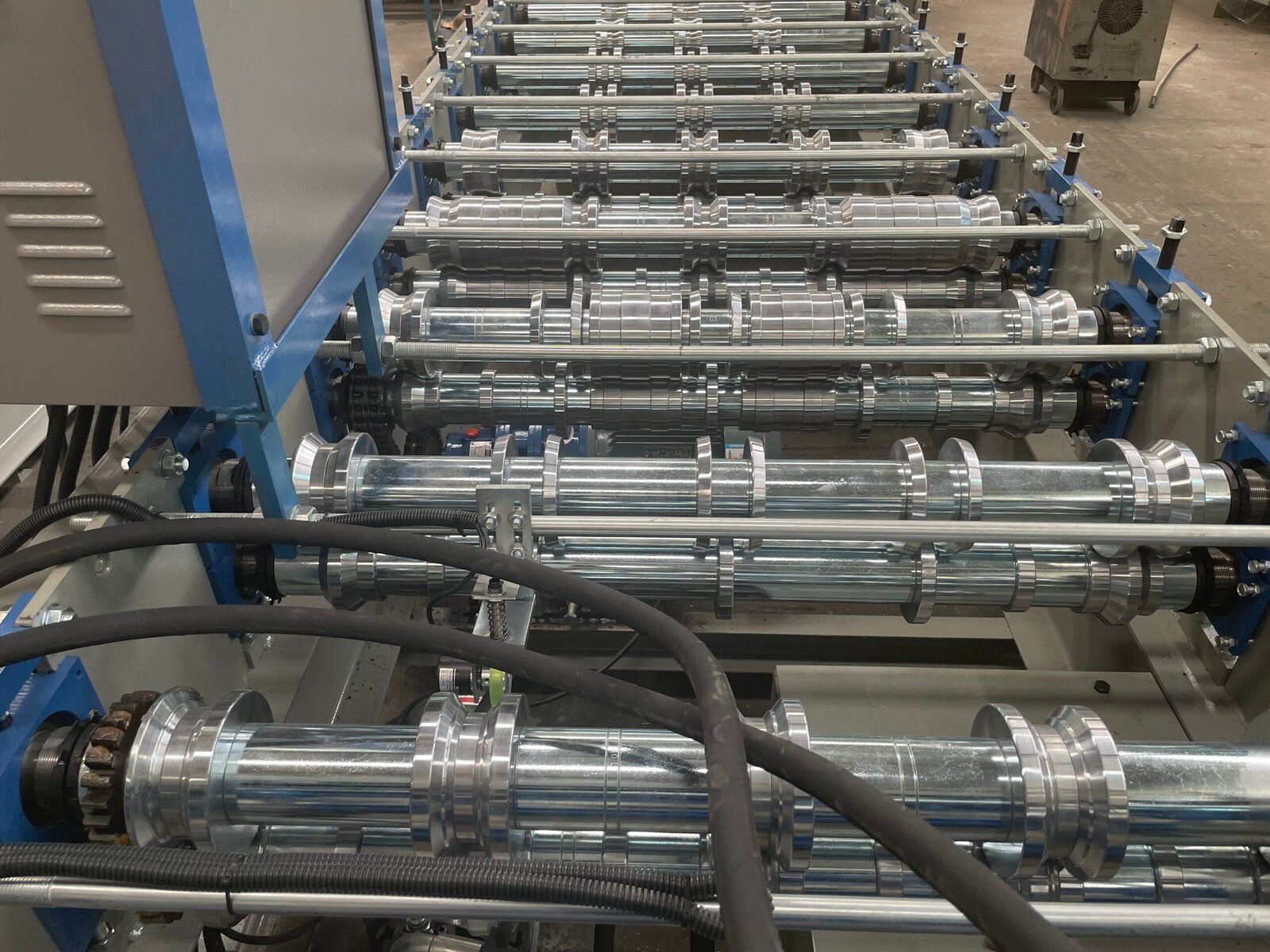

| 5 | Roll forming system | individual standing column structure |

| 6 | Safety cover | optional |

| 7 | Step pressing unit | Step length, depth, head & end length is adjustable |

| 8 | Post cutting | hydraulic |

| 9 | Output System / Stackmaster | Manual supporter/Automatic Stacker(optional) |

| Output direction(Lateral/Longitudinal)(optional) | ||

| 10 | Hydraulic system | Muanual or Power supply for decoiler / post-cutting system |

| 11 | Electric control system | MITSUBISHI/SIEMENSE/AMS(optional or as requested) |

Specifications of r panel roll forming machine

| Machine Condition | Fully New, A Grade quality |

| Panel Shape | As profile drawing and customers requirements |

| Operator needed | 1 person |

| Power Supply | 220V/380V/415V/460V, 50/60Hz, 3P (as requests) |

| Equipment Weight | About 8t |

| Dimension (LWH) | about 18*2.9*1.8m |

| LOADING SIZE | Normally need 1×40’/container |

| Equipment Color | Normally Blue/Gray, or as requests; |

| Place of Origin | Fujian, China (Mainland) |

| Packing | Standard and careful export packing |

Work flow

The common working process of the R panel roll former is much like other roll forming machine series made by Beenew machinery. Here are the steps involved:

– Coil charging Car (you can choose to use it or not)

– Decoiler (it can be passive or automatic)

– Front Shear (an optional part)

– Feeding and Guiding Table

– Filming Covering (an optional step)

– Roll Forming System

– Post-Cutting to length (using either hydraulic or motor power)

– Output Manual Supporter/Stackmaster (both are optional for handling the final product)

Application of R panel roll forming machine

R-Panels & PBR-Panels: Durable Roofing Solutions

Low-Maintenance & Aesthetic: Engineered as a durable, long-lasting alternative to traditional roofing materials, R-Panels and PBR-Panels are available in a wide range of colors to complement architectural aesthetics for both existing structures and new designs.

Structural Strength:

PBR-Panels: Feature an extended overlap section (purlin-bearing leg) between panels, enhancing load-bearing capacity and structural integrity.

Coverage Consistency: Both R-Panels and PBR-Panels provide 36″ coverage per panel, ensuring seamless installation.

Versatile Applications:

Designed for commercial, industrial, and steel-framed buildings.

Suitable for roofing and sidewalls, offering flexibility in design and functionality.

Performance Benefits:

Corrosion-resistant and weatherproof.

Ideal for projects requiring high strength-to-weight ratios.

These panels combine practicality, visual appeal, and industrial-grade performance, making them a preferred choice for modern construction needs.

Reviews

There are no reviews yet.