Efficient Steel Wave Flowerpot Roll Forming Machine for Durable and Stylish Planter Production

Machine Parameters

| Item | Value |

| Driving Motor | 15KW*2 |

| Forming Station | 20 |

| Roller Material | GCr15 |

| Shaft Diameter | 75/95mm |

| Shaft Material | 45# steel |

| Pump Motor | 7.5KW |

| Frame Type | Common weld wall |

| Cutting Type | Hydraulic Cutting |

| Control System | PLC |

| Main Electric Parts Brand | Simenz, Delta, Omron or Schneider |

| Cutting Length Precision | ±2mm |

| Machine Dimension | 10500*1150*1450mm |

| Electric Standard | 380V/50HZ/3Ph or customized |

| Paint Color | Grey White+bule or customized |

A steel flowerpot roll forming machine is specialized equipment designed to produce metal flowerpots efficiently and with high precision. Here’s an overview:

Key Features

- Decoiler: Holds and unwinds metal coils, usually made of galvanized steel or aluminum.

- Feeding System: Guides the metal strip into the roll forming machine accurately.

- Roll Forming Mill: A series of rollers that gradually shape the metal strip into the desired flowerpot profile.

- Cutting System: Cuts the formed metal into specific lengths, using hydraulic or mechanical cutting mechanisms.

- Control System: Uses PLCs (Programmable Logic Controllers) for precise control over the forming process.

- Output Conveyor: Transports the finished flowerpot sections for further processing or assembly.

Benefits

- High Efficiency: Continuous production process increases output.

- Precision and Consistency: Ensures uniform dimensions and quality.

- Cost-Effective: Reduces labor costs and material waste.

- Customization: Can produce various designs by changing roller dies.

Applications

- Garden and Landscaping: Produces decorative and functional flowerpots for residential and commercial gardens.

- Retail: Supplies products for garden centers and home improvement stores.

- Urban Landscaping: Provides durable solutions for urban gardening and public spaces.

Construction Process

- Design: Custom designs are created based on market demands.

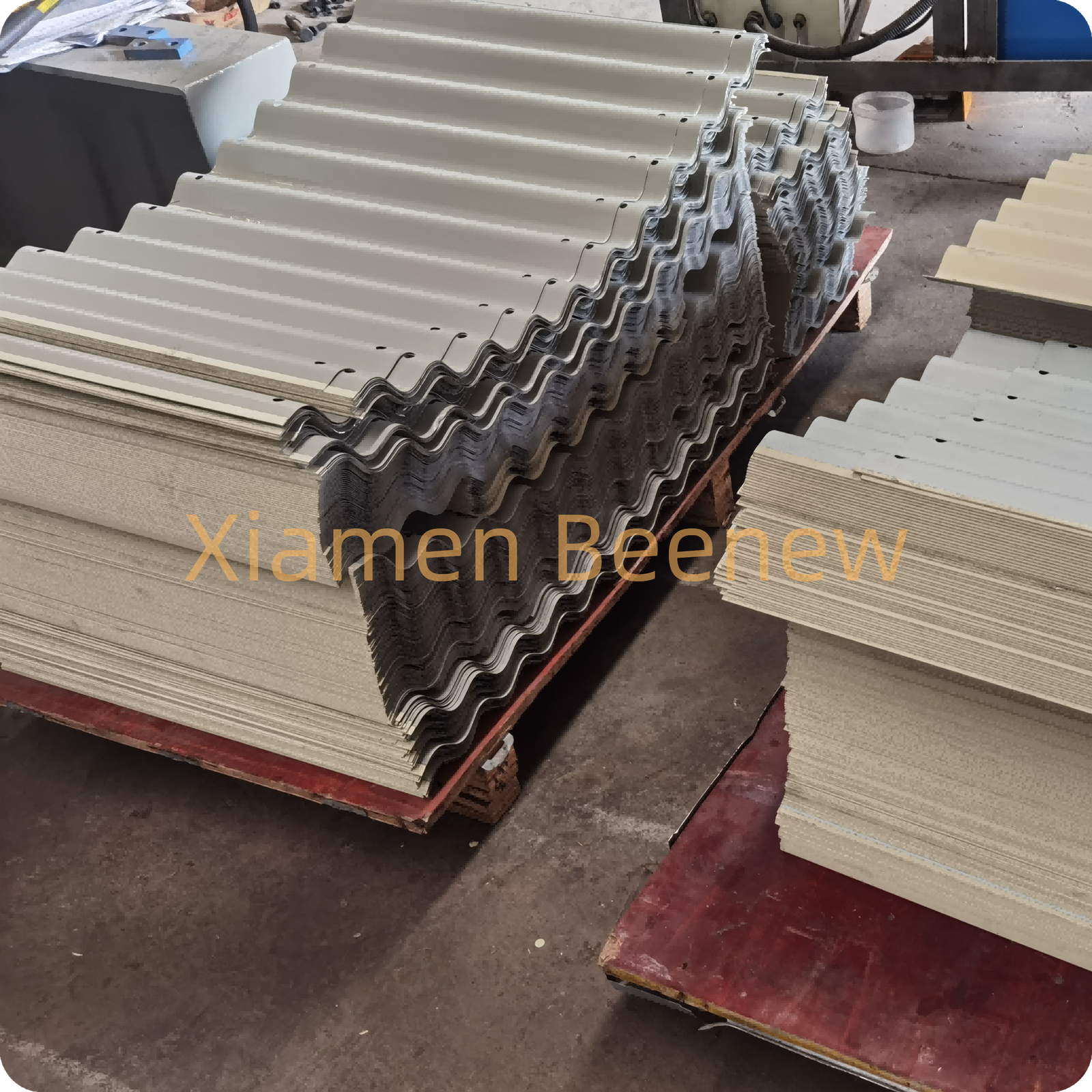

- Manufacturing: Metal coils are shaped into flowerpots in a factory setting.

- Transportation: Finished products are transported to distributors or directly to customers.

- Assembly: Some designs may require additional assembly or finishing touches.

Industry Impact

Steel flowerpot roll forming machines enhance the production capabilities of manufacturers, meeting the demand for durable and stylish garden products. They play a crucial role in the gardening and landscaping industry by providing efficient and customizable production solutions.

Reviews

There are no reviews yet.