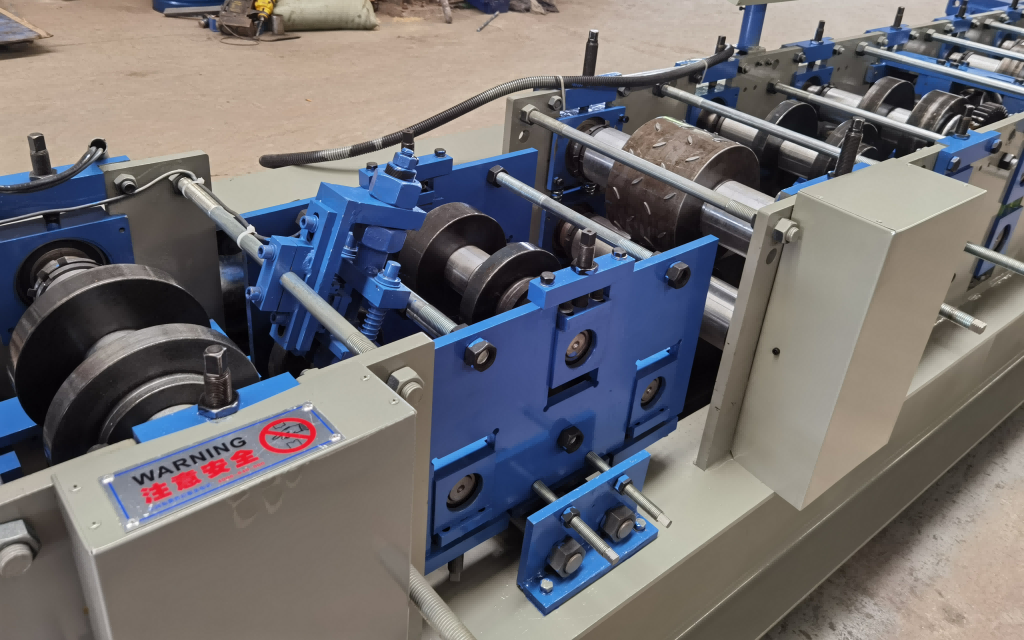

Metal Deck Roll Forming Machine

The Metal Deck Roll Forming Machine, also known as the Steel Deck Rolling Forming Machine or Metal Deck Rolling Forming Machine, is a state-of-the-art solution tailored for concrete floor construction. This machine revolutionizes the traditional form work process, offering unparalleled efficiency and cost-saving benefits.

Working Principle:

The working principle of the Floor Deck Rolling Forming Machine relies on its ability to roll-form panels that serve as direct replacements for traditional form work. The machine utilizes a series of rollers and dies to gradually shape and bend metal sheets into the desired deck profiles. This process is continuous and highly automated, resulting in faster and more precise production of decking panels.

Application Range:

The Floor Deck Rolling Forming Machine finds extensive application in the construction and building structure industry. It is particularly suitable for projects that require large quantities of decking panels, such as commercial buildings, industrial facilities, and multi-story residential complexes. The versatility of the machine allows it to produce a wide range of deck profiles, making it suitable for various design and structural requirements.

Advantages:

- Efficiency: The Floor Deck Rolling Forming Machine significantly reduces the working duration by up to 3 times compared to traditional formwork methods. This results in faster project completion and lower labor costs.

- Cost Saving: The use of pre-formed deck panels not only reduces the amount of concrete required but also leads to material savings of up to 30%. Additionally, the elimination of traditional formwork reduces the need for additional equipment and labor.

- Quality: The high level of automation and precision offered by the machine ensures consistent and reliable quality of the decking panels. This helps reduce wastage and rework during the construction process.

- Versatility: The machine can produce a variety of deck profiles to suit different design and structural requirements. This flexibility makes it a valuable asset for any construction project.

- Durability: The decking panels produced by the machine are sturdy and durable, able to withstand heavy loads and provide long-lasting support for concrete floors.

In conclusion, the Metal Deck Roll Forming Machine is a valuable addition to any construction project that requires efficient and cost-effective production of decking panels. Its unique working principle, wide application range, and numerous advantages make it a must-have tool for modern construction practices.

Reviews

There are no reviews yet.