Product Name: Metal Roof Forming Machine

Machine Parameters

| Item | Value |

| Driving Motor | 15KW*2 |

| Forming Station | 20 |

| Roller Material | GCr15 |

| Shaft Diameter | 75/105mm |

| Shaft Material | 45# steel |

| Pump Motor | 7.5KW |

| Frame Type | Common weld wall |

| Cutting Type | Hydraulic Cutting |

| Control System | PLC |

| Main Electric Parts Brand | Simenz, Delta, Omron or Schneider |

| Cutting Length Precision | ±2mm |

| Machine Dimension | 10500*1150*1450mm |

| Electric Standard | 380V/50HZ/3Ph or customized |

| Paint Color | Grey White+bule or customized |

Machine Overview

The Metal Roof Forming Machine with a Full Automatic Glazed Tile Roll Forming System is an advanced manufacturing solution designed to produce high-quality metal roof sheets and glazed tiles. This machine integrates automated processes to ensure precision, efficiency, and consistency in the production of roofing materials suitable for various architectural applications.

Machine Features

- Fully Automated Operation: The machine is equipped with an automated system that handles material feeding, roll forming, cutting, and stacking, minimizing manual intervention and maximizing efficiency.

- Precision Rollers and Dies: High-quality rollers and dies are designed to create accurate and consistent profiles, ensuring the finished product meets stringent quality standards.

- Adjustable Settings: The machine allows for easy adjustments to produce different sizes and styles of metal roof sheets and glazed tiles, enhancing its versatility.

- Durable Construction: Built with robust materials and components to ensure long-lasting performance and reliability even under high-volume production conditions.

- User-Friendly Control Panel: An intuitive interface simplifies operation, allowing operators to easily set and monitor production parameters.

Machine Advantages

- High Efficiency: The automation of the entire production process significantly increases output while reducing labor costs.

- Consistent Quality: Advanced roll forming technology ensures uniformity in the dimensions and quality of the produced metal roof sheets and glazed tiles.

- Low Maintenance: Designed for minimal maintenance with durable, wear-resistant components that ensure extended operational life.

- Flexibility: Capable of producing a wide range of roofing profiles and styles, making it suitable for various architectural designs and requirements.

- Enhanced Safety: Incorporates modern safety features to protect operators and maintain a safe working environment.

Product Application Range

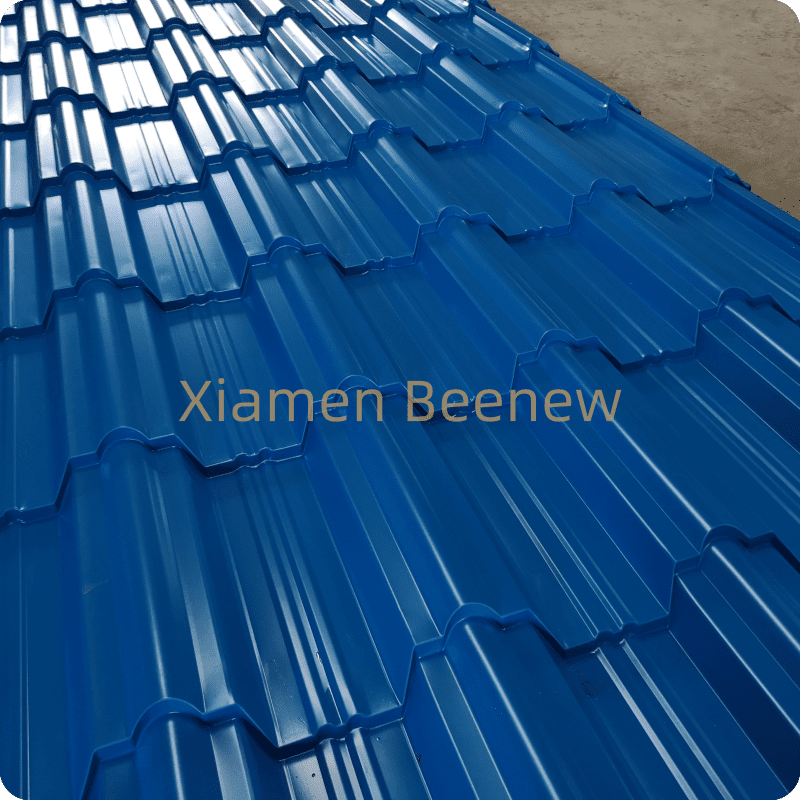

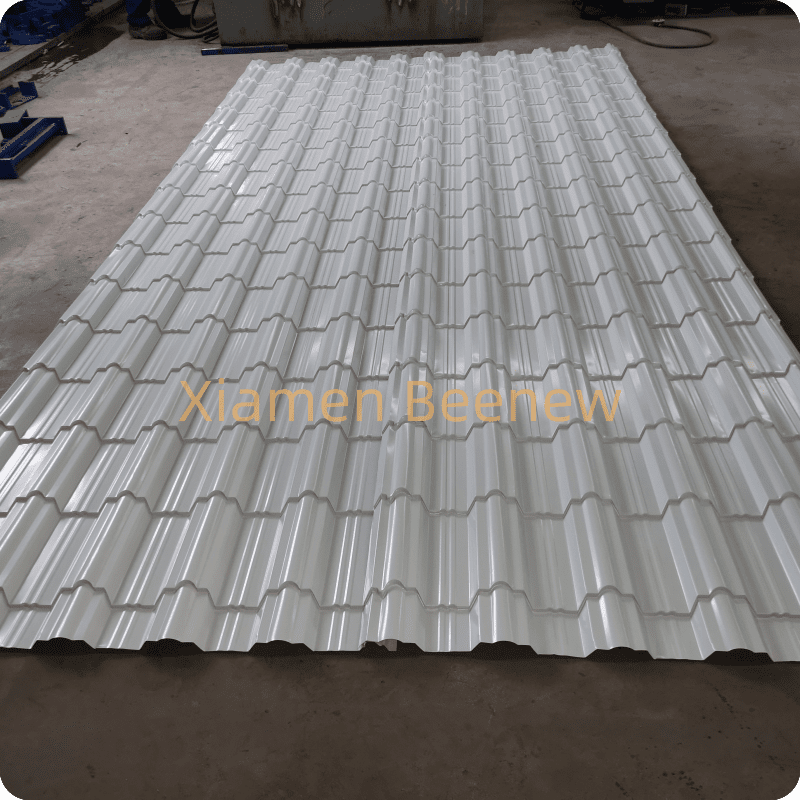

- Residential Roofing: Ideal for producing metal roof sheets and glazed tiles used in residential buildings, offering durability and aesthetic appeal.

- Commercial Roofing: Suitable for commercial buildings where strong, long-lasting roofing materials are required.

- Industrial Roofing: Used in the construction of factories, warehouses, and other industrial facilities, providing reliable protection and structural integrity.

- Architectural Projects: Perfect for architectural projects that require customized roofing solutions with specific profiles and designs.

- Renovation Projects: Applicable in the refurbishment of existing buildings, providing modern and durable roofing solutions.

Reasons to Choose Our Machine

- Superior Quality: Our machine ensures the production of high-quality roofing materials with precise dimensions and consistent performance.

- Advanced Technology: We employ the latest roll forming technology to enhance production efficiency and output quality, keeping pace with industry standards.

- Customization Options: The machine offers extensive customization capabilities, allowing you to tailor production to specific project requirements and design preferences.

- Comprehensive Support: Our dedicated customer service team provides thorough support, from installation and training to ongoing maintenance and troubleshooting.

- Cost-Effective Solution: By increasing production speed and reducing labor costs, our machine provides a highly cost-effective solution for manufacturing premium roofing materials.

Choosing our Metal Roof Sheet Making Machine with a Full Automatic Glazed Tile Roll Forming System ensures you receive a reliable, efficient, and versatile tool designed to meet the diverse demands of modern roofing applications.

Reviews

There are no reviews yet.