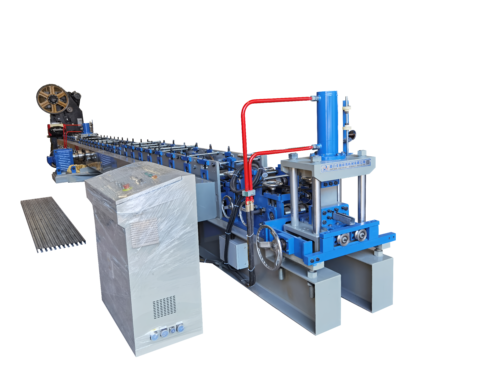

Machine Description

1. Jobsite Portability

We can manufacture iron container box for transporting the mobile roof roll forming machine ensures that it can be easily moved to different job sites. This feature is particularly advantageous for contractors who require on-site manufacturing capabilities, providing convenience and flexibility in various working environments.

2. Automated Control System

The PLC control system control all the roll forming processing action automatically, ensuring precision and consistency in panel production. This system reduces the need for manual intervention, increases efficiency, and minimizes the likelihood of errors, resulting in high-quality roofing panels.

3. Portable Design

The standing seam roof machine’s compact and portable design ensures it can be easily transported and produce at various job sites. This mobile roof sheet roll forming machine is particularly beneficial for large construction projects or remote locations where on-site manufacturing is required.

4. Roof Height & Width are Adjustable

The ability to produce panels with a 25mm roof height and interchangeable effective widths offers versatility, catering to different architectural styles and customer preferences. This adjustability ensures that the machine can meet a wide range of roofing specifications.

5. Suitable for PPGI and Aluminum Sheet

This Portable Standing Seam Machine is capability to process both aluminum and PPGI steel sheets makes it a versatile tool for various roofing applications. Aluminum provides lightweight and corrosion-resistant properties, while PPGI steel offers durability and a variety of color options for aesthetic appeal.

6. Break Down Style Forming Shafts

The breakdown style of the forming shafts allows for easy maintenance and quick adjustments. This design feature minimizes downtime, enhances productivity, and ensures that the machine can be quickly adapted to different production requirements.

7. High-Quality Forming Rollers

The forming rollers are made from GCr15, a high-grade bearing steel known for its hardness and wear resistance. The hard chrome coating further enhances the rollers’ durability and provides excellent anti-rust properties, ensuring long-lasting performance and reducing maintenance requirements.

Reviews

There are no reviews yet.