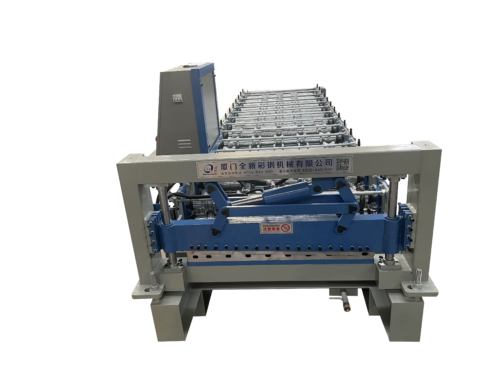

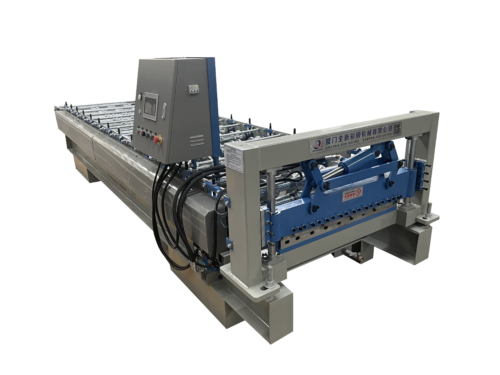

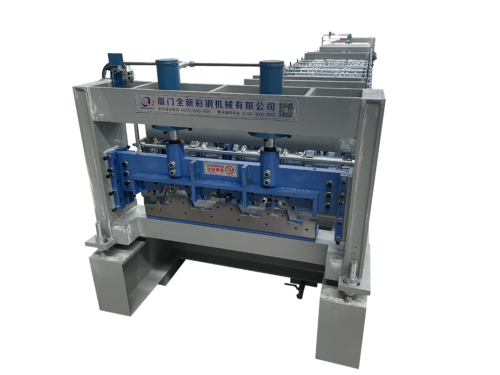

Deck Floor Roll Forming Machine

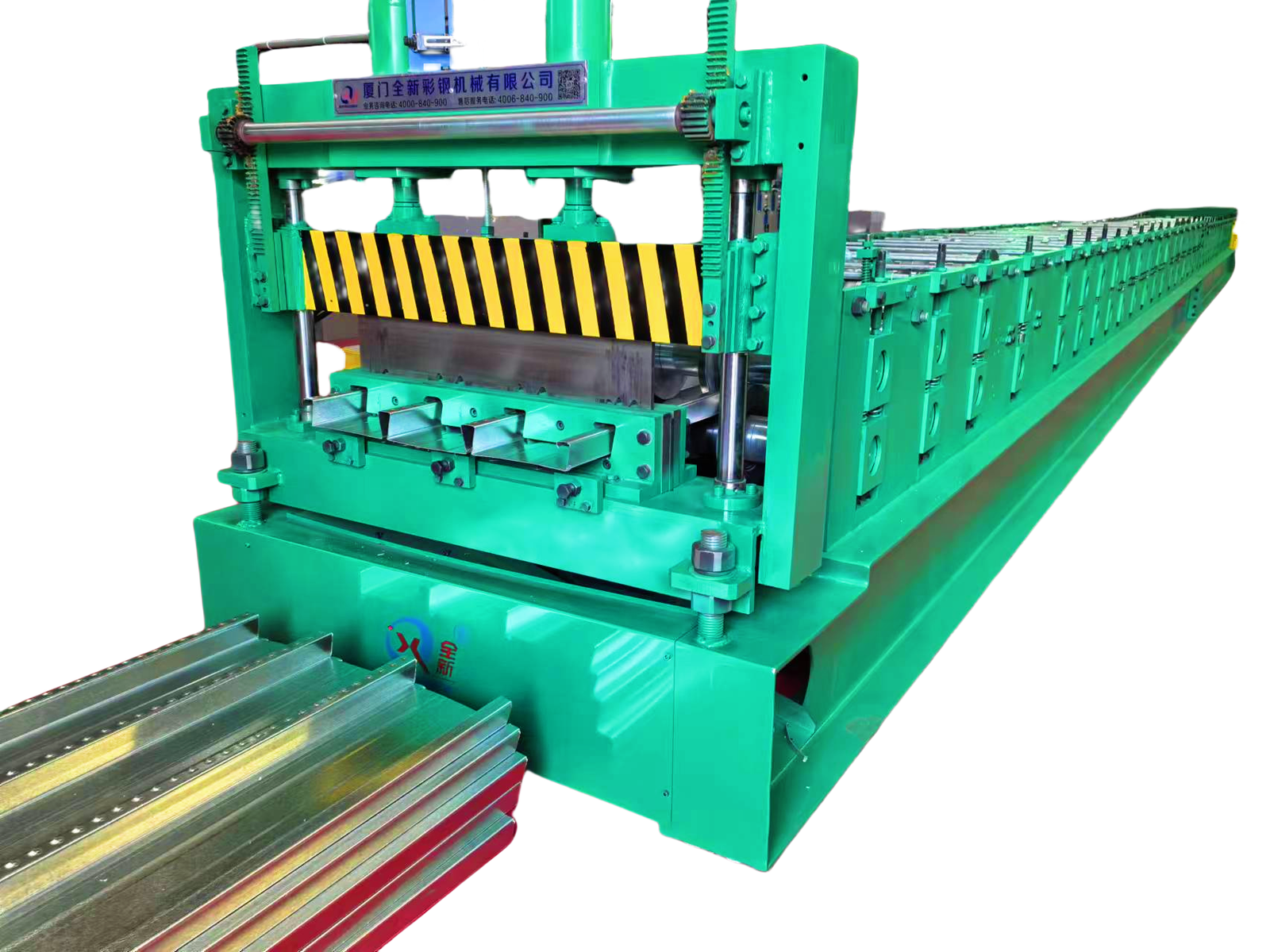

This deck floor roll forming machine is designed to produce indented floor decks , also called dovetail floor deck. Dovetail floor deck is named because the cross-section resembles a swallow’s tail, usually with lower rib height (40-60mm) and smaller rib spacing, which can effectively improve the overall stiffness of the floor slab. The indentation design enhances the mechanical occlusion between the steel plate and the concrete, reducing the risk of slippage and eliminating the need for additional shear reinforcement. It is popular because it combines the lightness of open-ended decks with the occlusion advantages of closed-ended decks, and its fire resistance and cost are also in between.

Machine Parameters

| Item | Parameters |

| Material | 1.0-1.2mm G550 Galvanized cold-rolled strip |

| Material Feeding Width | 1000mm |

| Driving Motor | 30KW( 15KW+15KW Hard Toothed R Series Reducer) |

| Hydraulic Motor | 5.5KW |

| Machine Frame | H400 Steel Base, 18mm thickness wall plate |

| Shafts Diameter | Φ90mm |

| Roller Material | 45# steel,fine-finished,heat treated and outer surface planting |

| Forming Station | 36 stations |

| Forming Speed | 16M/Min |

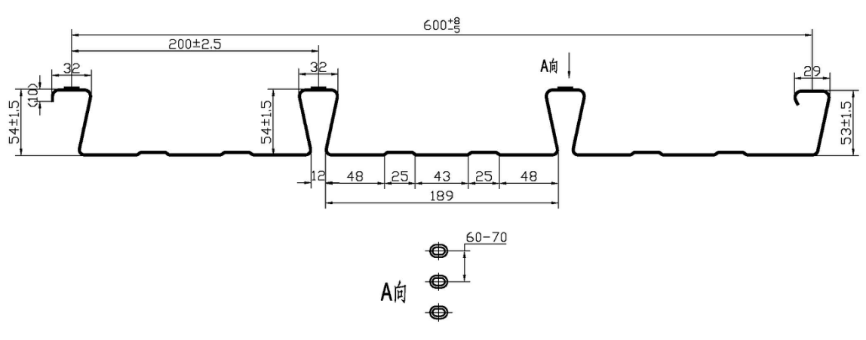

Profile Drawing

Be able to deal with high tension galvanized steel coil, this metal deck forming machine is designed to have 36 station in total. After roll forming by these rollers, the floor deck size is accurate, and the whole plate surface is straight and not deformed. All rollers are fine-processed and hard-chrome coated after planting which can make all rollers durable and anti-rust.

Be able to deal with high tension galvanized steel coil, this metal deck forming machine is designed to have 36 station in total. After roll forming by these rollers, the floor deck size is accurate, and the whole plate surface is straight and not deformed. All rollers are fine-processed and hard-chrome coated after planting which can make all rollers durable and anti-rust.

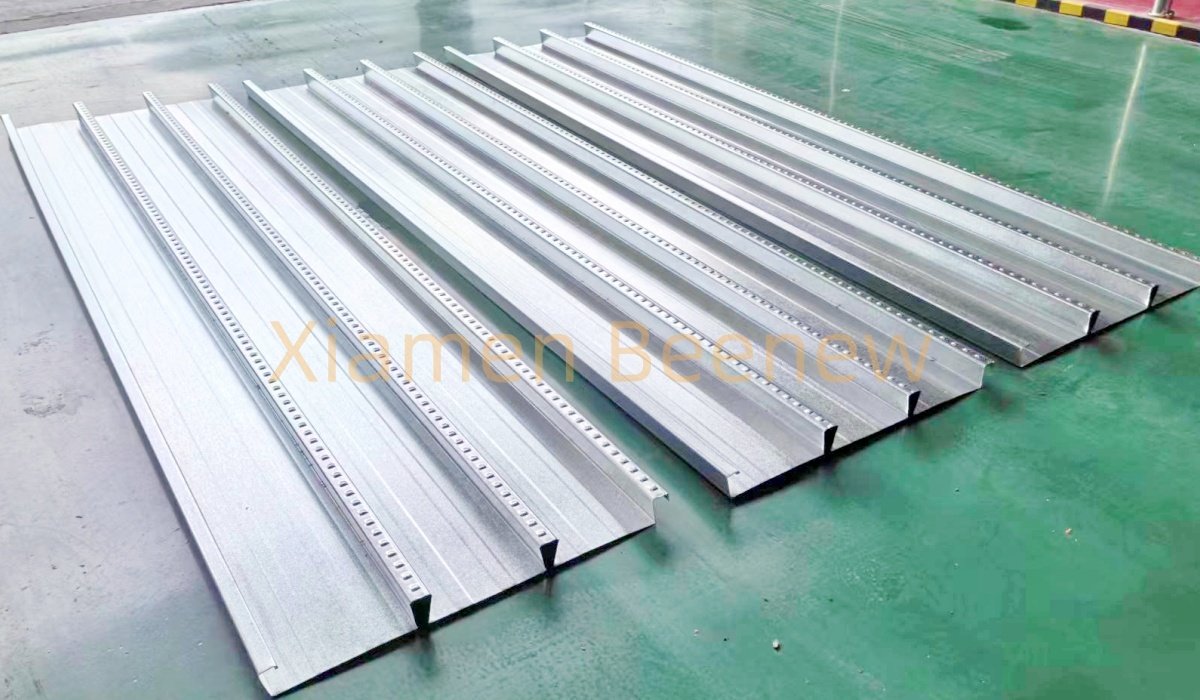

Floor Deck Sample

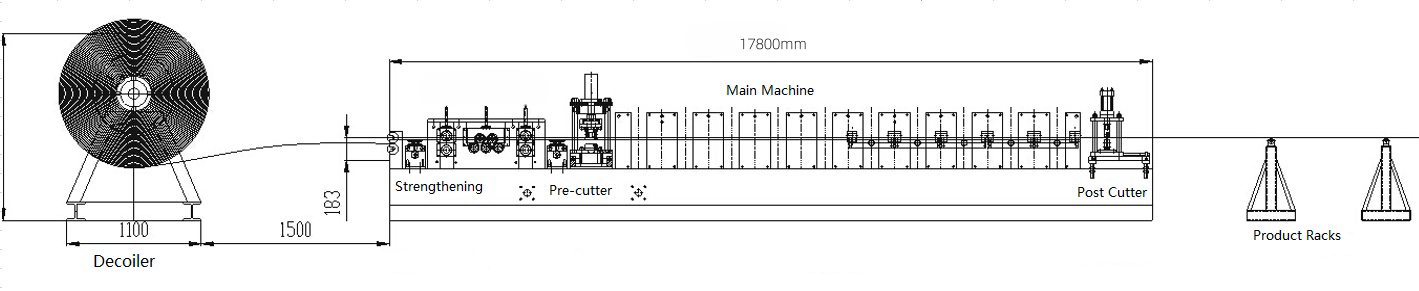

The whole work flow of this machine set is:

De-coiler — Feeding Guide/Strengthening — Pre-cut — Roll Forming Mill — Embossing Pressing Device — Hydraulic Post Cutting Device — Exit Rack*3

Construction Scene Diagram

This dovetail floor deck is designed to have concrete pouring on it. And the amount of concrete is less than the general floor deck sheet, which saves the cost to a certain extent. It is suitable for buildings that require high stiffness and fire and corrosion resistance, with a larger span than general floor decking, and relatively simple construction.

Reviews

There are no reviews yet.