Double Layer Roll Forming Machine

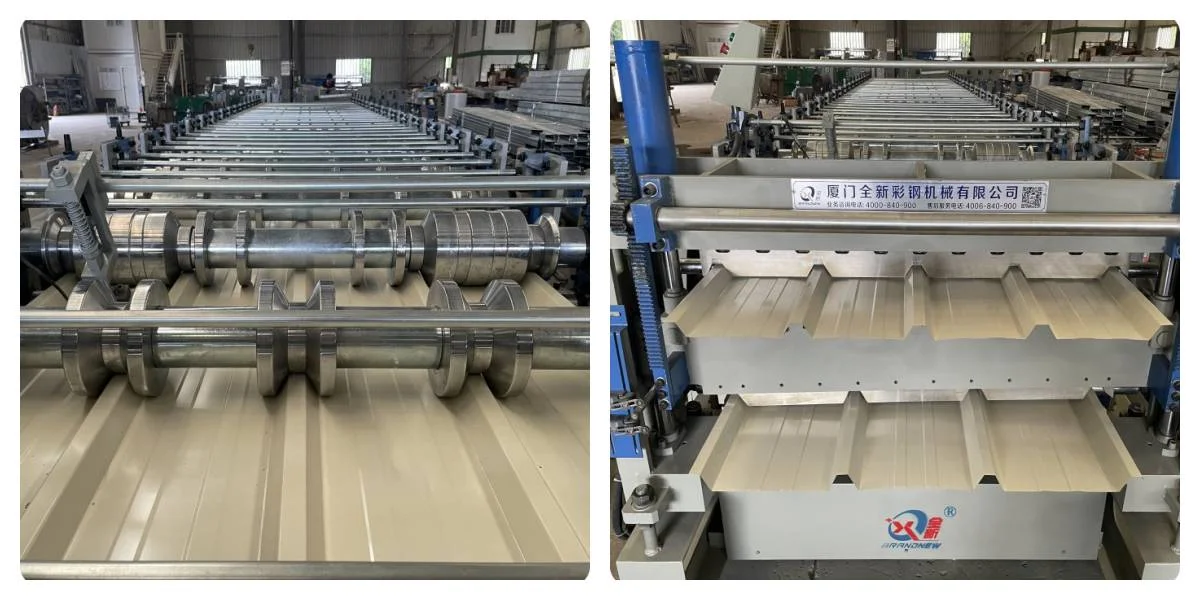

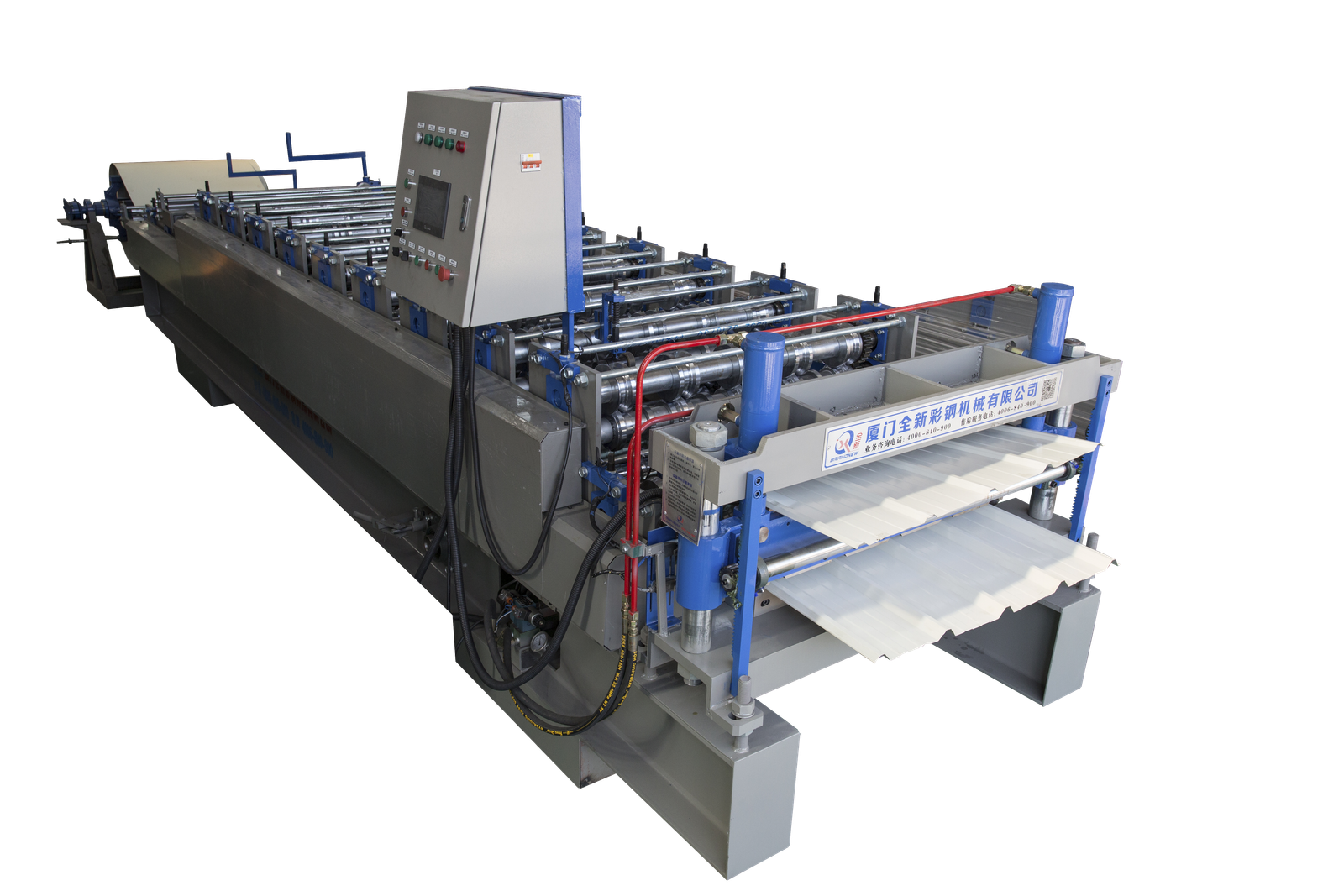

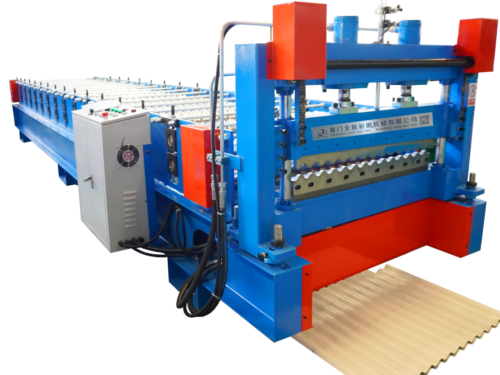

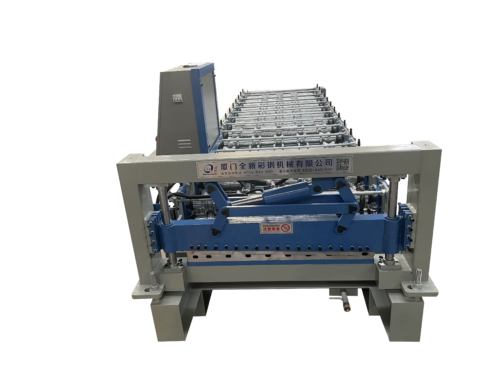

The roll forming machines we import are made by the professional team at Beenew. They use high-grade components and the latest technology to ensure that each machine strictly meets the industry quality standards. With this excellent equipment, we are fully committed to the supply of various double-layer forming machines.

No matter what your needs are, we can rely on automatic double-layer roofing roll forming machines to accurately produce any type of metal roof panels, wall panels or corrugated panels. From design to finished product, we closely follow customer requirements throughout the process and are committed to creating the most suitable products for you,such as:

1. Roof Tile Corrugated roll forming machine

2. Wall tile Corrugated making machine

3. Roof Tile & wall tile production line

4. Double Layer Roll Forming Machine

5.2 IN 1 roll forming machine

A double layer roll forming machine is engineered to manufacture two distinct types of metal sheets simultaneously. These combinations include:

1. Trapezoidal roofing sheets paired with corrugated roofing sheets.

2. Trapezoidal sheets and metal roof tiles.

3. Corrugated sheets and metal glazed roof tiles.

It should be noted that the two layers of the double – layer roll forming machine cannot operate simultaneously. This is because a single PLC control system stores the specifications for only one type of sheet, such as cutting length and production quantities. The double – layer roll forming parts share the same motor. In this double – layer machine, the switch between the operation of the top and bottom roll forming parts is achieved through a clutch.

Double layer roll forming machine price

The price of a roofing sheet roll forming machine is determined according to the drawing provided by the customer and their budget. It’s easy to find a used panel roll forming machine almost anywhere. However, if you’re aiming for long – term, trouble – free operation of a roof tile forming machine with minimal maintenance requirements, you are advised to send us the drawing of the roofing sheet profile. Our experienced engineers will then design a metal roof making machine tailored to your needs.

Based on the actual demands for roof and wall panels both domestically and overseas, Beenew Machinery has set up a roofing machine manufacturing operation. In its own workshop, it has manufactured and installed over 30 different profile roof panel machines. Therefore, if any customer requires galvanized or color – coated roof and wall panels, they can get in touch with Beenew Machinery. Metal roof tile systems present numerous advantages, such as:

The product features an extended lifespan

It also offers cost – efficiency

It can withstand extreme weather conditions

It comes with extensive warranties, giving you peace of mind.

It is environmentally friendly

Application

Reviews

There are no reviews yet.