Steel Door Making Machine

Machine Advantage

1. Automated Control System:

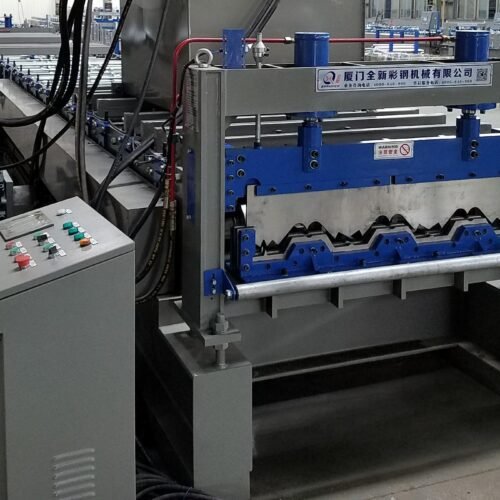

PLC System: The machine uses a PLC (Programmable Logic Controller) system for automatic control, ensuring precision, consistency, and efficient production.

Easy Operation: Automation reduces the necessity for manual intervention, minimizing human error and increasing productivity.

2. Efficient Material Handling:

Leading Roller Group: A leading roller group is designed to streamline the feeding of the steel coil into the roll forming machine, ensuring smooth and accurate material handling.

3. Enhanced Material Preparation:

Straightening Rolls: The machine is equipped with 5 straightening rolls that help level the steel coil, making it more flat and even. This preparation step improves the final product’s quality.

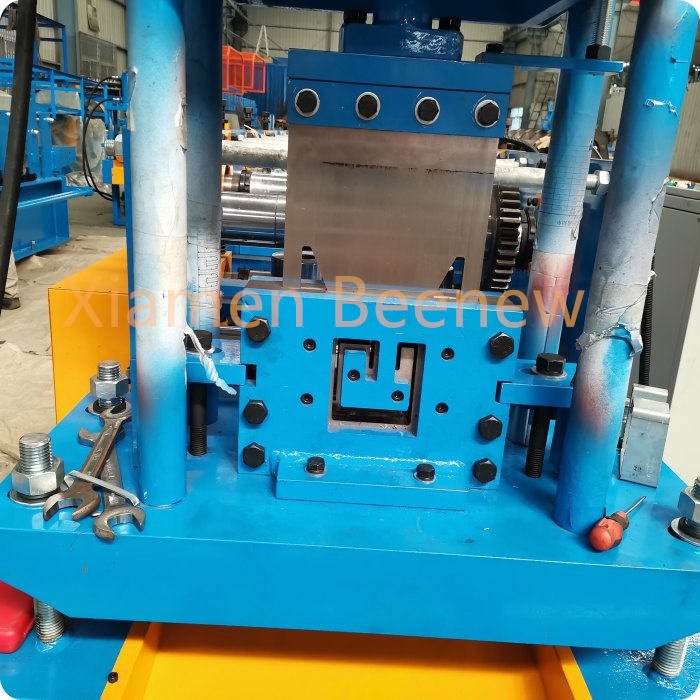

4. Adjustability:

Handwheel Adjustment: The inclusion of a handwheel allows for easy adjustment of the straightening span between the up and down rolls. This feature provides flexibility and ease of operation, allowing adjustments to be made quickly and efficiently.

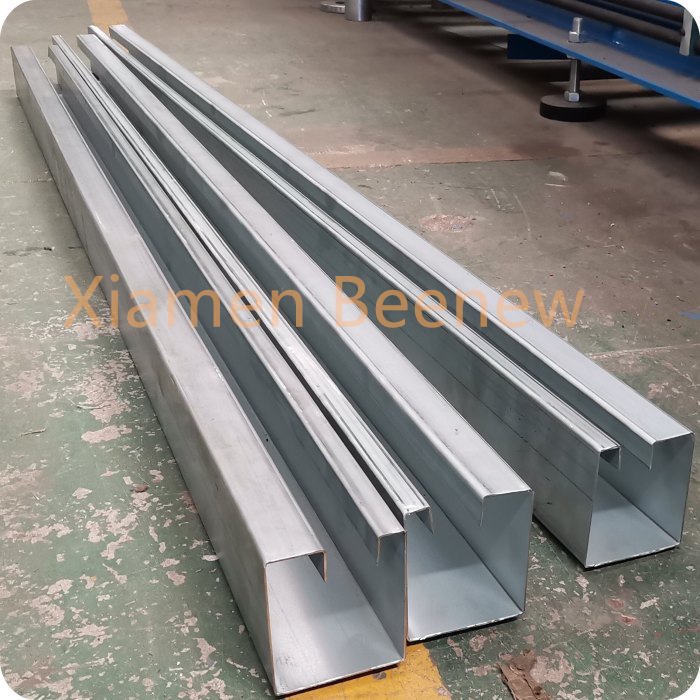

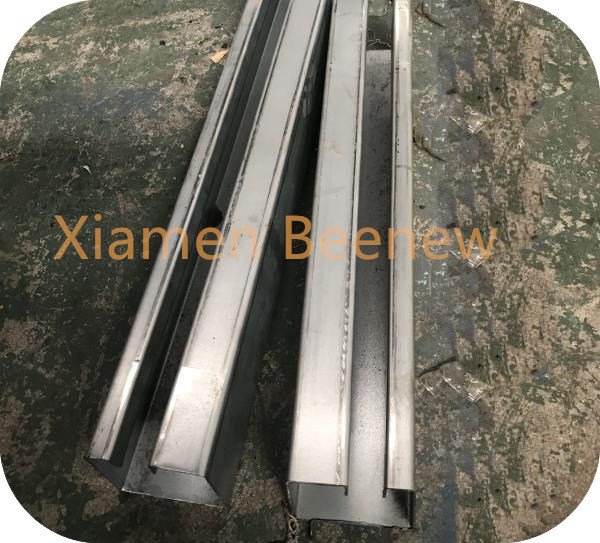

5. Quality and Precision:

Flatness Control: The combination of straightening rolls and adjustable spans ensures that the steel coil is processed with high precision and flatness, leading to superior quality outcomes for the final product.

6. Operational Efficiency:

Consistent Output: With a PLC system and precise straightening mechanics, the machine ensures a consistent and high-quality output, which is essential for large-scale production needs.

7.User-Friendly Design:

Ease of Use: The machine’s design, featuring automation and adjustable components, makes it user-friendly and easy to operate, reducing the learning curve and increasing operational efficiency.

These advantages make this Steel Rolling Door Frame Roll Forming Machine a highly efficient, precise, and user-friendly piece of equipment for producing high-quality steel door frames.

Machine Parameters

| Item | Value |

| Driving Motor | 11KW |

| Forming Station | 16 |

| Roller Material | 45# steel |

| Shaft Diameter | 75mm |

| Shaft Material | 45# steel |

| Pump Motor | 4KW |

| Frame Type | Common weld wall |

| Cutting Type | Hydraulic Cutting |

| Control System | PLC |

| Main Electric Parts Brand | Simenz, Delta, Omron or Schneider |

| Cutting Length Precision | ±2mm |

| Machine Dimension | 8500*1250*1450mm |

| Electric Standard | 380V/50HZ/3Ph or customized |

| Paint Color | Grey White+Blue or customized |

Reviews

There are no reviews yet.