Step Tile Roll Forming Machine

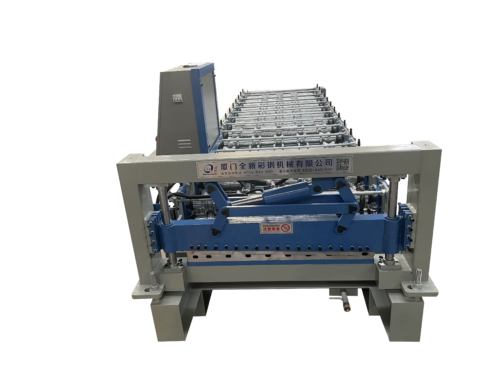

Beenew’s step tile roll forming machine is a bespoke solution meticulously crafted for our clients in Kazakhstan. Tailored precisely to meet the specific needs of our customers, this machine stands out for its unique features.

Firstly, it is equipped with an oil spraying device. During the production process, this device applies lubricating oil to the metal tiles. This ensures that the metal roof tiles are well-lubricated, preventing any scratches on the plates when they are being transported or stacked.

Secondly, the machine comes with a coder. As the roof tiles are being produced, the coder imprints the code specified by the customer on the back of the tiles. This enables the end customer to trace the origin of the product easily.

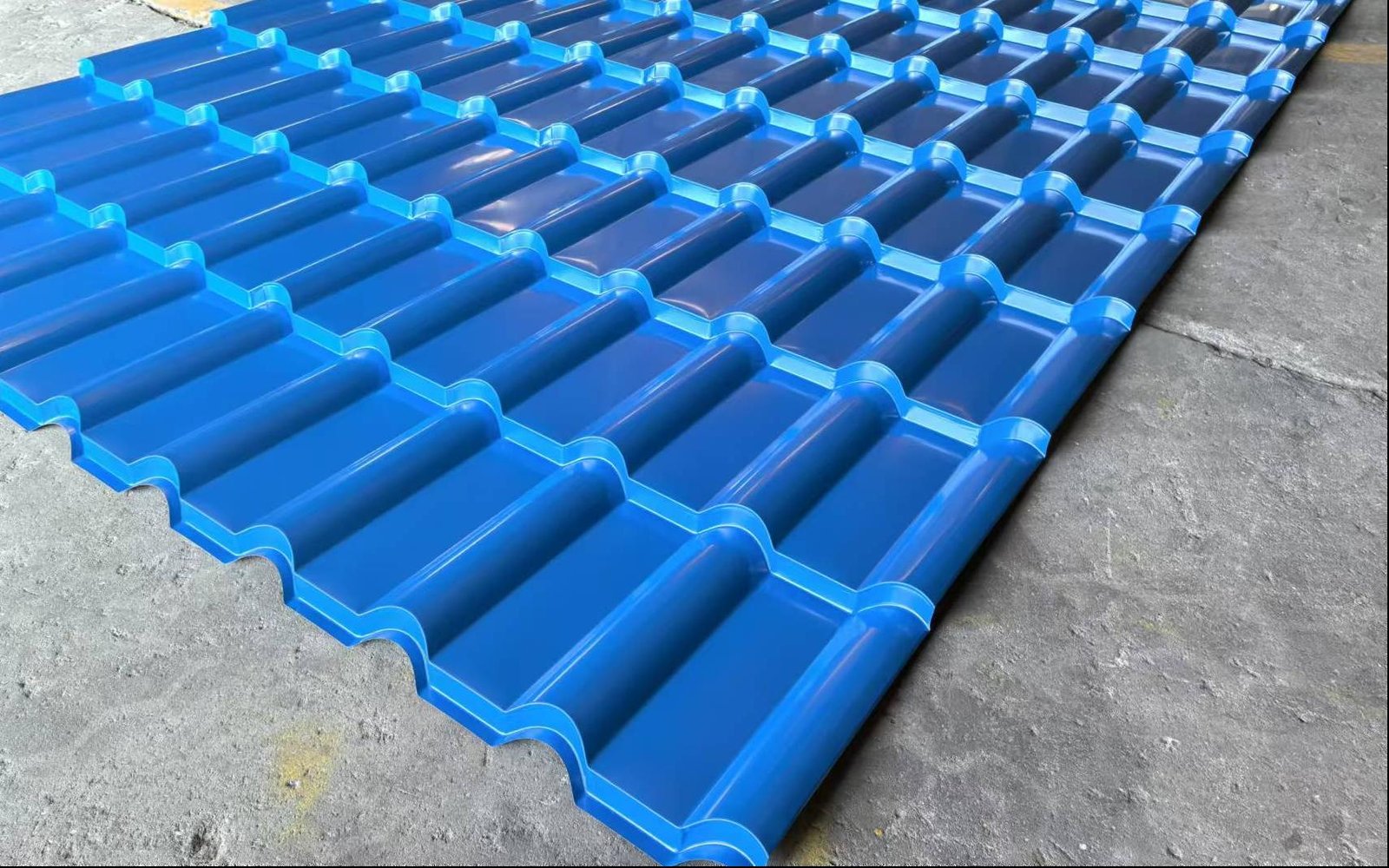

The glazed tiles manufactured by Beenew’s glazed tile roll forming machine bear a striking resemblance to traditional earthen glazed tiles. However, they have distinct advantages, being lighter in weight and more durable. These qualities make them highly popular and widely utilized in the modern steel structure construction industry.

Beenew Machinery is not limited to the production of metal tile forming machines. Our roll forming machines have found extensive applications across various other industries as well. If you are interested in having a cold roll forming machine customized to your needs, please feel free to reach out to us.

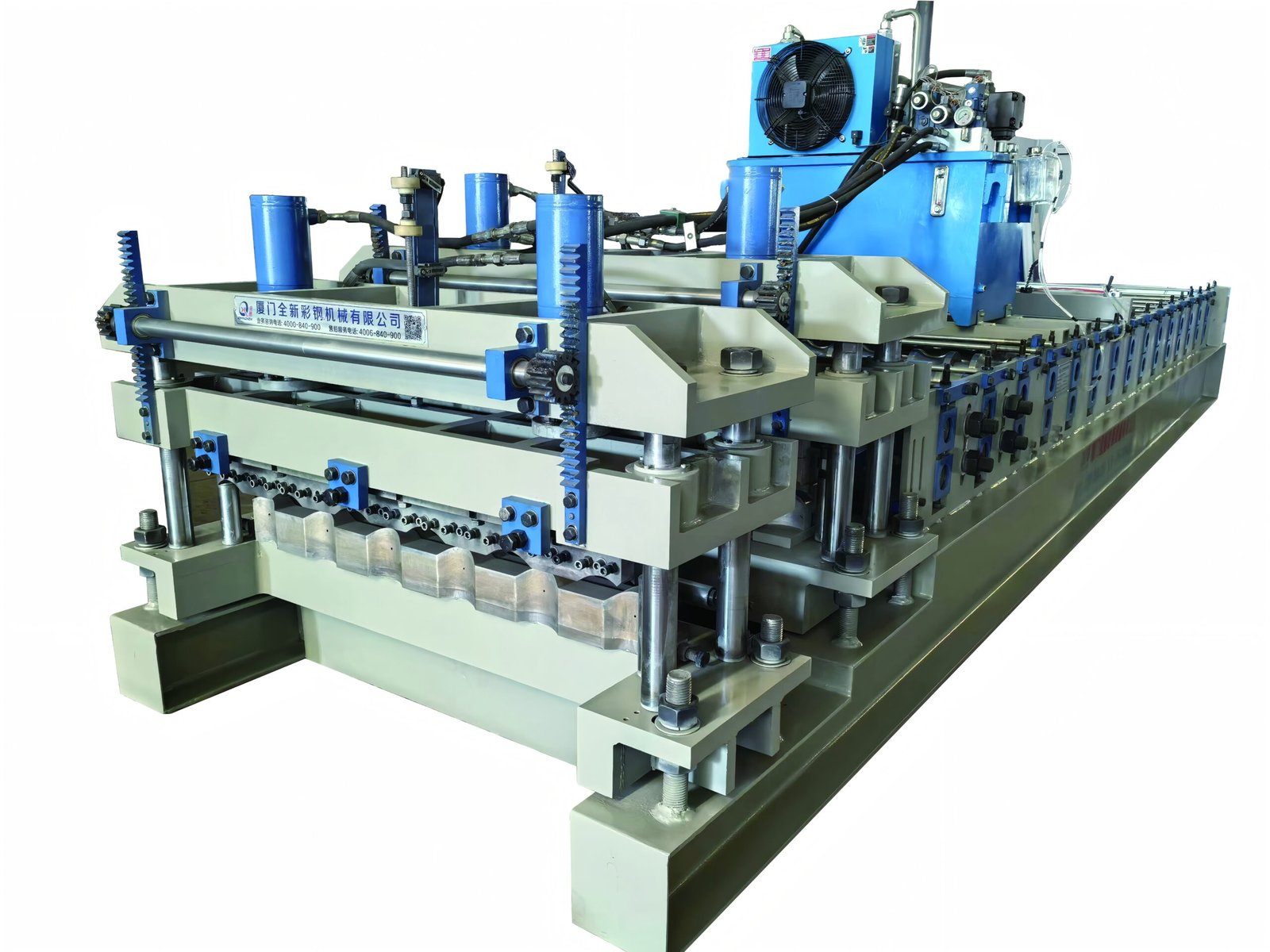

Main Machine

1.Roll station: 20 stations, just main forming rollers;

2.Main motor power: 11KW, it adopts cycloid cone pulley reducer, chain or gearbox transmission;

3.Roller Material: 45# steel;

4.The roller finishing, surface hard chrome plating and brushed polishing;

5.Shaft Material: 45# forged steel;

6.Shaft Diameter: φ80mm;

7.Machine frame: welding by 346 x 174mm H shape steel;

Electric Control System

1.Control system: PLC

2.Operation platform: touch screen and press button

3.Main motor: AC frequency conversion electric motor

Main Parameters

| Driving Motor | 11KW |

| Forming Station | 20 |

| Roller Material | 45# steel |

| Shaft | 45# steel,φ80mm |

| Pump Motor | 3.0KW |

| Cutting Type | Hydraulic Cutting |

| Control System | PLC |

Video

Reviews

There are no reviews yet.