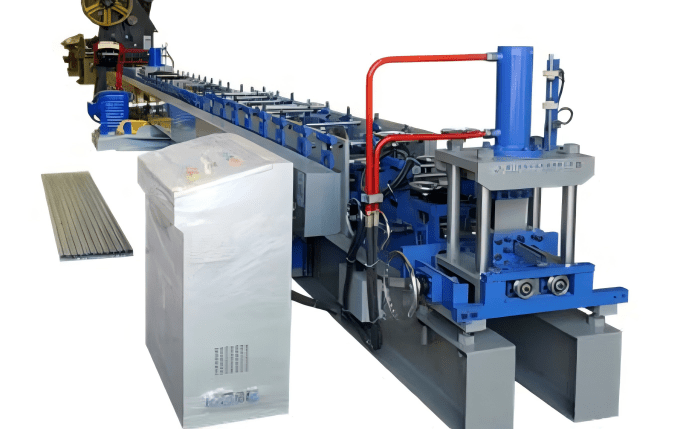

Unistrut Channel roll forming machine

Beenew‘s Unistrut Channel roll forming machine is customized for our Australian customers. It is used in the roof system of the solar photovoltaic system as a support frame to support the solar photovoltaic panels.

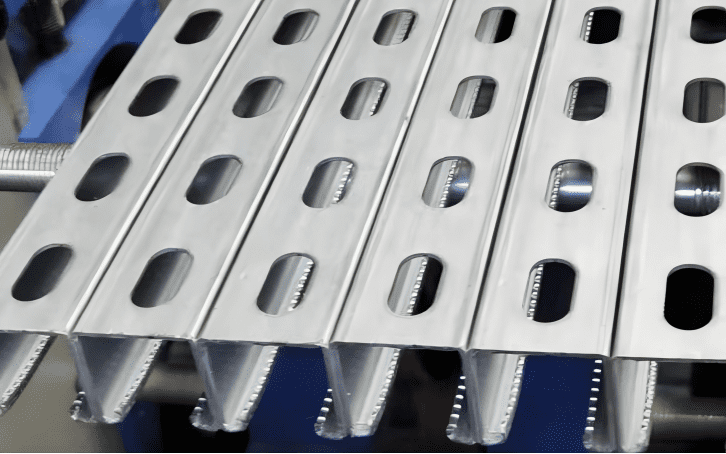

Profile

The material used for this unistrut roll forming machine is Q235 galvanized sheet or Q355 aluminum zinc magnesium sheet, the thickness of the sheet is 1.2-2.5mm; the width of the steel coil material is about 98/138/158/178/198mm.

The roller material of the forming machine is mold steel CR12, which has been heat treated and has a hardness of HRC60-62. The main motor is two 15 kW power, and the forming speed reaches 25-30m/min.

As China’s leading roll forming machine manufacturer, Beenew machinery has 27 years of industry manufacturing experience, and can customize various forming machines required by various industries for customers. Please contact us as soon as possible.

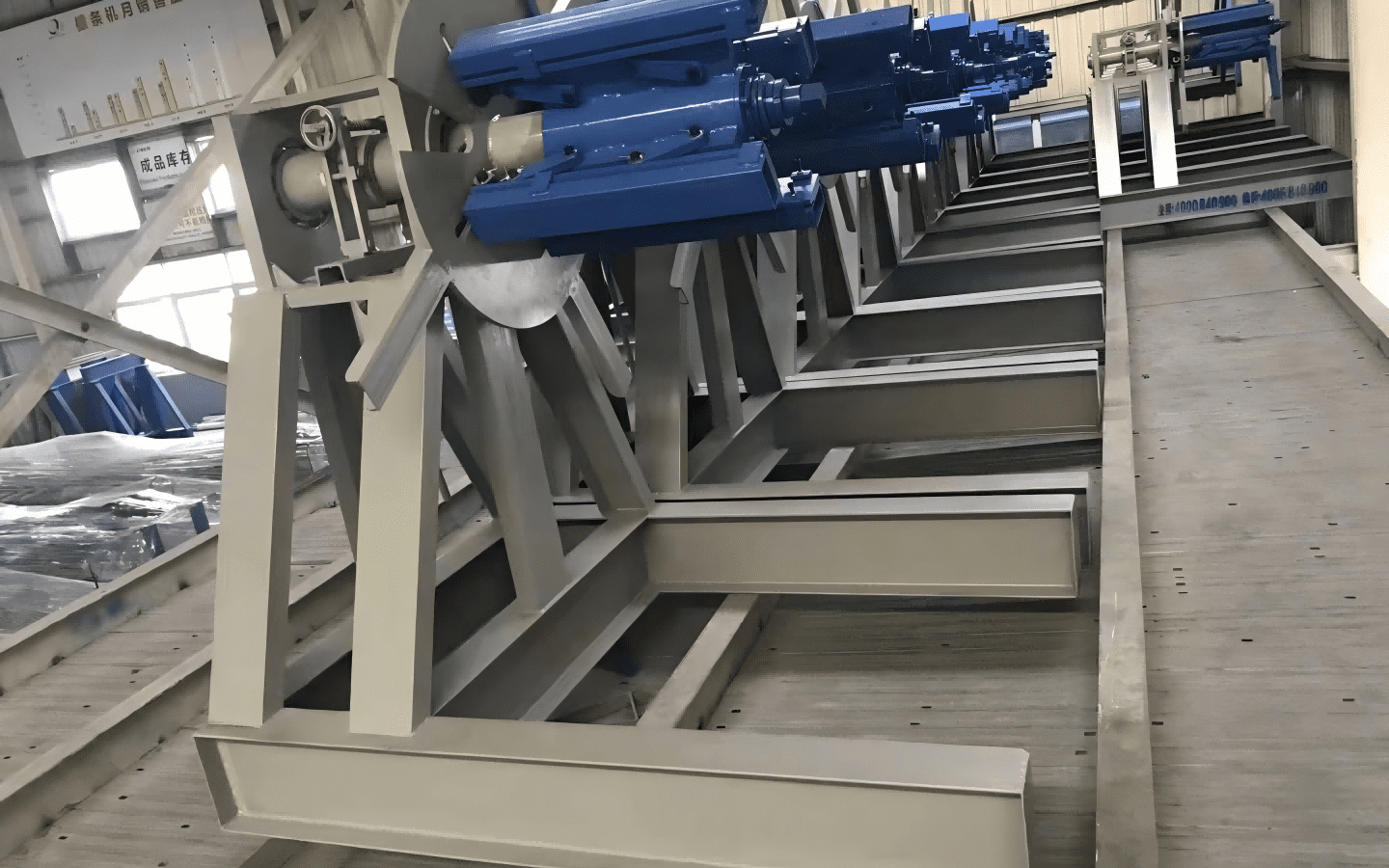

Application scenarios

Machine Parameters

| Item | Parameters |

| Driving Motor | 15KW*2 |

| Forming Station | 26 |

| Roller Material | CR12 |

| Shaft Diameter | 75mm |

| Shaft Material | 45# steel |

| Pump Motor | 7.5KW |

| Cutting Type | Hydraulic Cutting |

| Control System | PLC |

| Machine Dimension | 18860*1400*1300mm |

Reviews

There are no reviews yet.