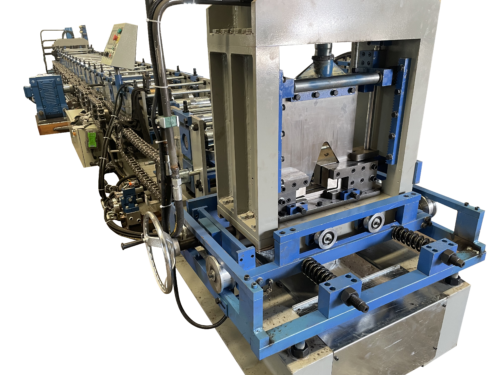

Purlin Roll Former

Beenew CZ30030 Purlin Roll Former

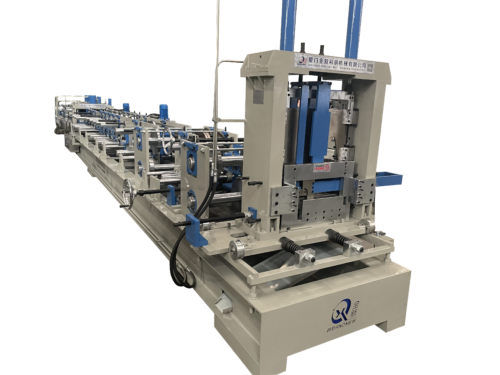

A highly sought-after purlin machine in the Indian market, delivering unparalleled precision and efficiency in crafting premium CZ purlins. This cutting-edge machine integrates 20 sets of roll stations, driven by a heavy-duty gearbox for smooth, high-speed operation. Its servo motor-powered system ensures pinpoint accuracy and reliable performance, tailored for mid-to-high-end industrial demands.

With a material width range of 80-300mm and thickness compatibility from 1.0-3.0mm, the CZ30030 effortlessly meets varied purlin production needs. The streamlined 13-meter conveyor system enhances workflow efficiency, while its intuitive design prioritizes ease of operation and low-maintenance functionality.

Opting for the CZ30030 Purlin Roll Former means embracing a top-tier solution that elevates productivity and product quality. Built with state-of-the-art technology and durable components, this machine is the definitive choice for businesses aiming to produce flawlessly engineered CZ purlins with industry-leading efficiency and consistent excellence.

| Machine Quick Details | |

| Model number: CZ30030 | Condition: New |

| Type: CZ Purlin machine | Brand Name: Beenew |

| Max Production Capacity: 30m/min | Power(W): 22KW |

| Warranty: 2 years | Place of Origin: China |

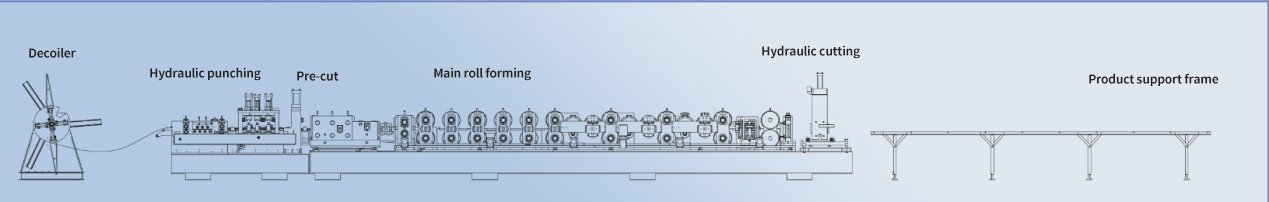

Work Flow

Decoiler – Leveling device — pre- punching and pre-cutting – roll forming line – Product rack

Video

The Advantages of CZ purlin roll forming machine

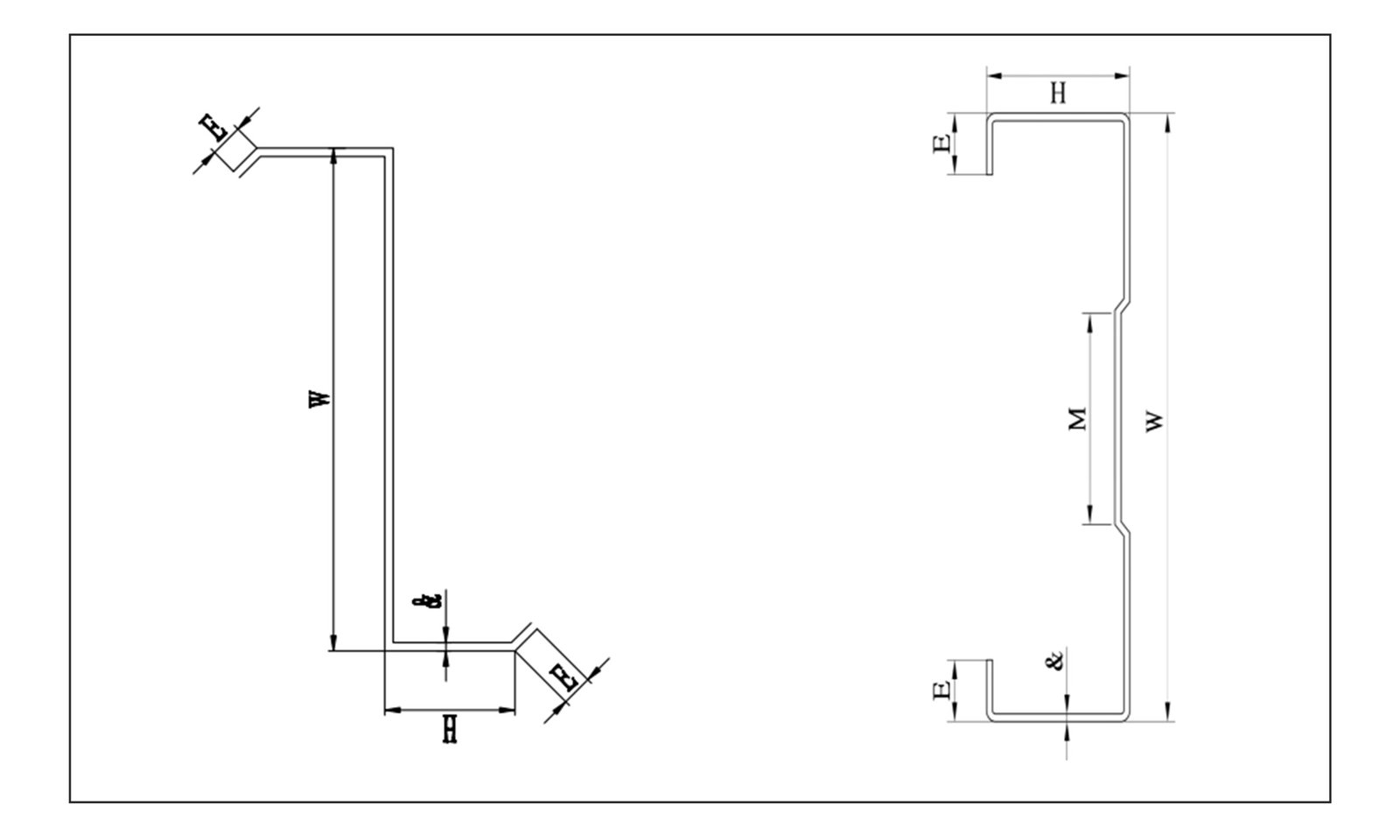

1. Versatile Sizing Capability: It is capable of manufacturing purlins in a diverse range of sizes. For C purlins, it can produce sizes from C80 to C300, and for Z purlins, from Z120 to Z300.

2. Consistent Cutting Mechanism: The machine eliminates the hassle of changing the cutter when dealing with different purlin sizes.

3. User-friendly and Economical: The operation of the CZ purlin roll forming machine is straightforward, making it accessible even for operators with relatively little experience.

4. Material-saving Infinite Sizing: With its infinite sizing feature, the machine can produce purlins of any size within its specified range.

5. Flexible Punching Options: An optional feature of the machine is the ability to punch holes at any position on both the web side and the flange side of the purlin.

Main Components

1. Hydraulic Decoiler

Coil Inner-diameter=510±30mm

Coil Outer-diameter Max. 1300mm

Load Capacity: Max. 5 Tons

Coil Width Max. 600mm

2. Pre-Leveling Device

7 shafts to leveling, Precision Machined, hard Chrome Coated

3. Hydraulic Pre-punch Pre-cut Device

With hydraulic pre-cut for cutting material head

Stop to punch, pre-punch

Total 3 cylinders for punching

Slot hole size: 9*25mm,10*25mm,13*25mm

Total 3 sets punching dies

manual changing punching dies if needed

Pump motor: 11KW

Cutting pressure=Max.16Mpa

Punching dies and cutting tool material: Cr12MoV

4. Pre – cutting Equipment

It is applied to cut raw materials prior to roll forming.

5.Main Roll Forming M/C

Feeding section with guider

One side one motor at material feeding end for type-change

Gear/ sprocket driving: 20 steps to form+3 steps for shaping

Side wall thickness: 30mm

Shaft diameter: 90/75mm

Shaft material: 45# steel, Precision Machined

Rollers manufactured from GCr15 and Cr12, CNC lathes, hard Chrome Coated

Frame base material: H450

Main motor =30KW (servo motor), with reducer, Frequency speed control

forming speed: 20-30m/min (without punching and cutting)

Touch screen input datas for changing different sizes producing

Automatic adjust CZ purlin bottom width and flange height

Manual cassette change producing C or Z shapes

Fast C/Z interchange achievable in just 3 steps, within 5 – 15 minutes.

6. Post Universal Hydraulic Cutting Device

All sizes changing set work can be finished on touch screen

Post cut, universal cutting off

Cutting blades material: Cr12MoV

The suitable blades width and flange height can be adjustable as need

Pump motor =11KW (shared with pre-punching device)

7.Product track —2 set

Un-powered, 2 pcs, 6meters long total

8. PLC Control System

Control the cutting length & quantity automatically

Combined with:PLC, inverter, Touch Screen, Encoder, etc

PLC screen set purlin size for for changing types

Cut-to-length tolerance≤±2 mm

Control voltage 24V

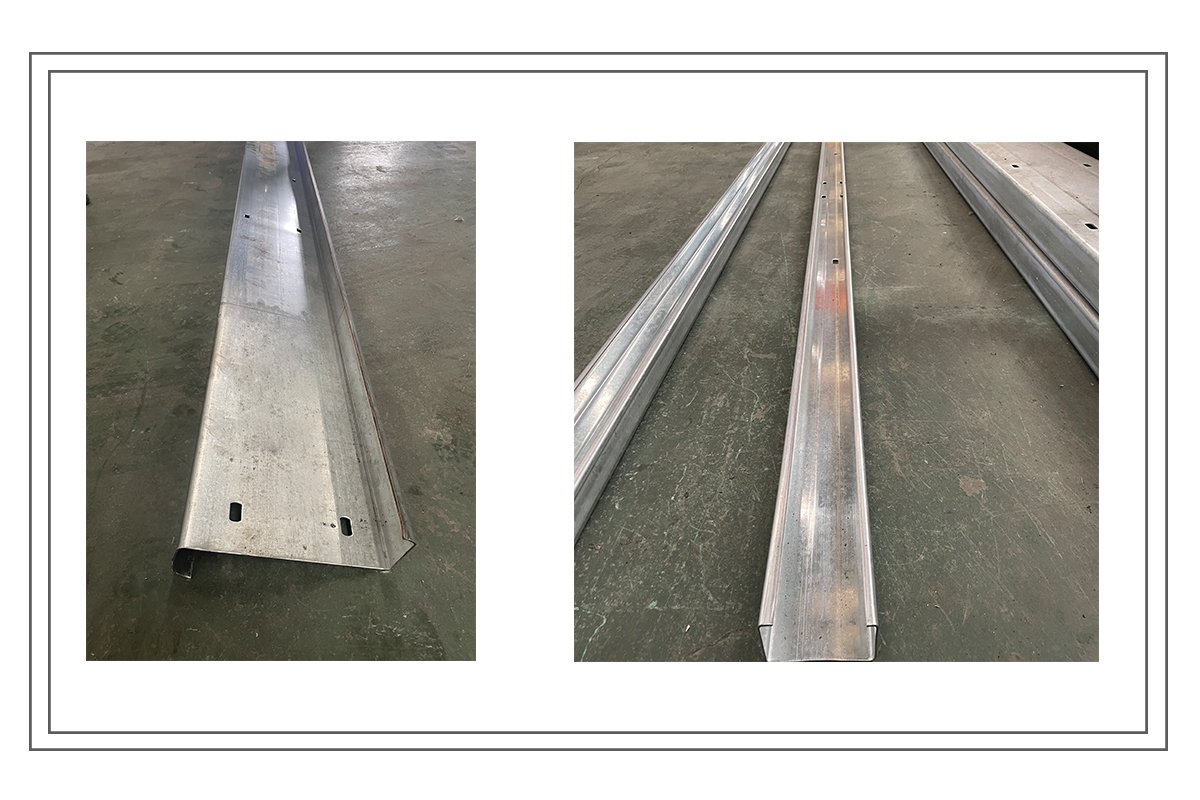

9.Product-CZ purlin

Our factory

Why Choose us:

– Boasting 28 years of expertise in manufacturing CZ purlin roll formers.

– Offering products with competitive prices and high – quality standards.

– Providing a 2 – year complimentary warranty.

– Ensuring a rapid response in after – sales service.

– Capable of automatically adjusting web size from 100mm to 300mm within 5 minutes.

– Open to customization according to clients’ specific needs.

– Featuring user – friendly operation and straightforward maintenance.

– Having self – developed post cutters, where a single blade can cut all sizes of final products.

Reviews

There are no reviews yet.