Roofing Sheet Forming Machine

The Beenew high-speed Roofing Sheet Forming Machine specializes in crafting metal roof sheets, corrugated metal plates, steel rooftiles, and the like. Employing fly cutting technology within its roll forming capabilities, this machine achieves an impressive operational speed of up to 30-40 meters per minute (excluding cutting time).

What is steel roofing sheets?

Metal roofing is a type of roofing material that uses metal sheets as roofing materials, combining the structural layer and the waterproof layer into one.

There are many types of metal sheets used to produce metal roofing, including galvanized sheets, aluminum-zinc sheets, aluminum alloy sheets, aluminum-magnesium alloy sheets, titanium alloy sheets, copper sheets, stainless steel sheets, etc.

Application

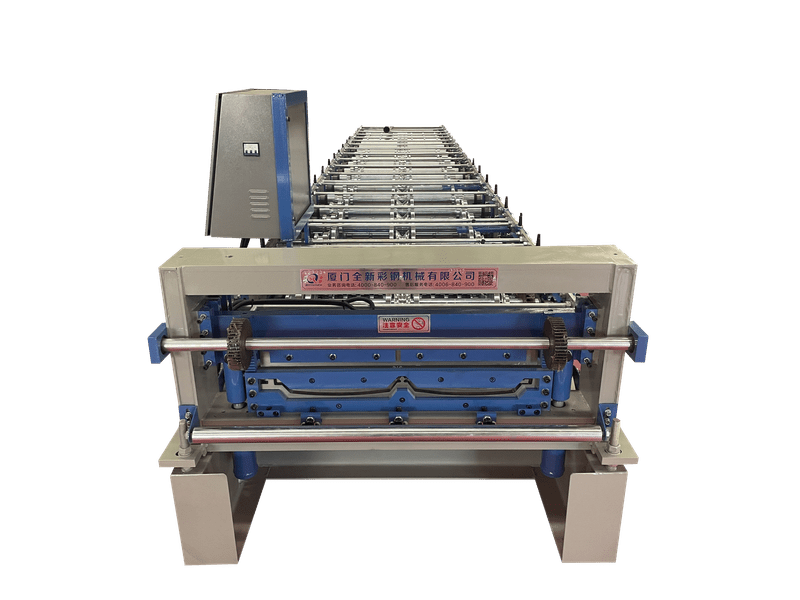

Main Machine

1.Roll stand: 13stations, it includes leveling rollers, main forming rollers

2.Main Motor Power: The machine is equipped with a powerful 5.5KW motor, which utilizes a cycloid cone pulley reducer for efficient power transmission, complemented by either chain or gearbox drive systems for smooth operation.

3.Roller Material: Crafted from 45# high-grade steel, the rollers undergo chrome plating for enhanced durability and corrosion resistance.

4.Roller Precision: The rollers are precisely machined using CNC technology, ensuring dimensional accuracy. The surface finish undergoes a meticulous polishing process, achieving a surface roughness of 0.05mm for smooth and seamless metal forming.

5.Main Shaft Material: The main shaft is constructed from 45# forged steel, which undergoes heat treatment to improve its strength, wear resistance, and overall durability. This ensures the shaft can withstand the rigorous demands of continuous metal forming operations.

6.The diameter of the main shaft: Ф65mm

7.Machine frame: welding by H298*149mm H shape steel, by using carbon dioxide gas arc welding. The surface used shotblasting treatment.

Electric Control System

1.Control system: PLC

2.Operation platform: touch screen and press button

3.Main motor: AC frequency conversion electric motor

Product produced by roofing sheet forming machine

Reviews

There are no reviews yet.