Sandwich panel machine

The BN 500 PU/PIR/Rockwool Continuous Sandwich Panel Production Line is an all – in – one multifunctional equipment set. It is engineered to execute a series of processes such as decoiling, film cutting, conveying rock wool or glue, preheating, foaming, heating, cutting, air cooling, stacking, and packing.

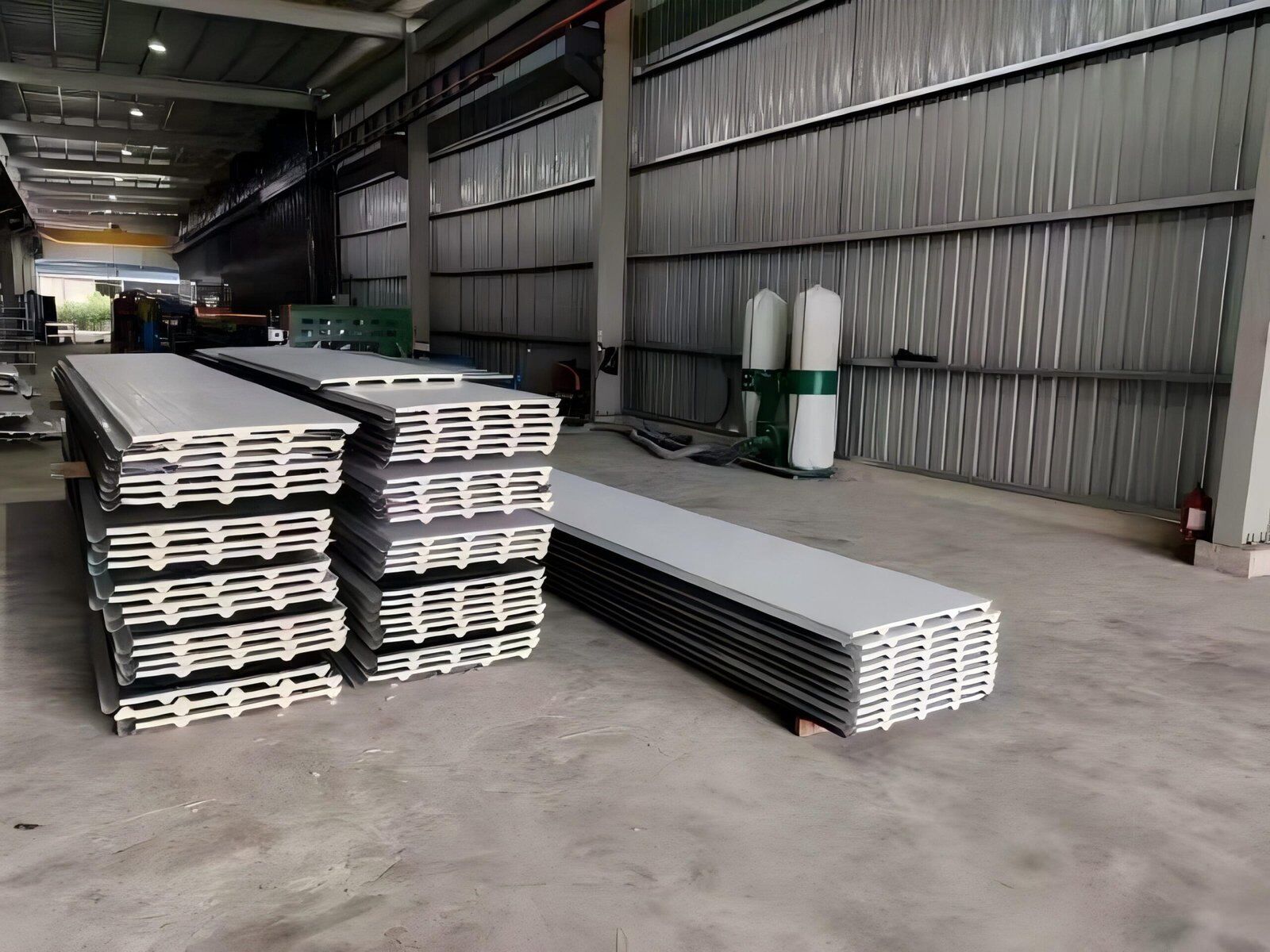

This production line is applied to manufacture sandwich panels. These panels find wide applications in industrial buildings, wall decoration, livestock farming, cold storage facilities, and other fields.

Specification: sandwich panel line

Production speed range (m/min): 3 – 7, with adjustable settings

Effective length of double – belt conveyor: 16000 – 40000mm, providing flexibility in production

Pouring foam work pressure: 150 – 200 Bar, ensuring proper foam application

Total power consumption: Approximately 200kw, indicating energy requirements

Overall dimensions (L*W*H): (100 – 200)m × (16 – 30)m × 6m, giving a clear idea of the equipment’s size

Suitable raw material

Type: Color Steel Sheet, Stainless Steel Sheet, Aluminum Sheet

Available thickness range: 0.4 – 0.8 mm for Steel Sheet, 0.35 – 0.6 mm for Stainless Steel Sheet

Maximum width: 1250mm

Maximum weight options: 6T or 10T

Available core materials: PU, PIR, Rockwool, Glass Cotton

The general specification of PU panel

Panel Length: Ranging from 2000mm to 18000mm

Panel Width (mm): Varying between 600mm and 1200mm

Panel Thickness(mm): 30 – 200mm, and 250mm for Cold Storage Panel

Machine components

Roll forming system

A double – headed roll forming machine is available for the upper layer profiles. The width of this roll forming machine is adjustable. Its forming system consists of double – sided, independent sets of rolling shafts, and the frame can be adjusted within a specific range.

Rockwool system

The rock wool system encompasses a rock wool lifting device, a rock wool slitting device, a rock wool turning device, an upper and lower foam spraying system, a two – components side sealing foaming machine, a dust collecting device, and a conveyor, among others.

Pre-heating system

The continuous sandwich panel production line is equipped with a hot air circulating heating furnace. This furnace plays a crucial role in keeping the temperature for polyurethane foaming and curing at an appropriate level. Thanks to this, the produced sandwich panels achieve a high standard of quality.

The panels manufactured by our Polyurethane Sandwich Panel Line possess multiple excellent properties. They are highly effective in heat preservation and insulation, capable of reducing heat transfer significantly. Additionally, they offer remarkable sound insulation, effectively blocking out external noises. These panels also have strong fire retardance, enhancing safety in various applications. Moreover, their water resistance ensures durability even in humid environments. With this machine, you can produce panels that not only look aesthetically pleasing but also are highly practical, meeting diverse needs for different projects.

Reviews

There are no reviews yet.