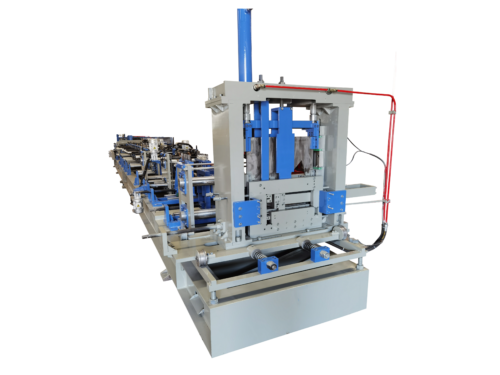

U Channel Roll Forming Machine

The Beenew U Channel Roll Forming Machine is designed to fabricate U-shaped channel profiles from galvanized steel coils.

U channels serve a multitude of purposes, including structural support, safeguarding delicate panel edges as edge protection material, and organizing cables as cable trays and tracks.

This particular forming machine was customized to meet the needs of a Japanese client, where the produced U-shaped profiles are utilized as decorative building materials, notably as ceiling keel channels. Furthermore, Beenew manufactures an extensive range of U channel machines in various types and sizes, offering customization to suit individual requirements.

All Beenew roll forming machines come with a comprehensive 2-year warranty covering both parts and the machine itself. Each machine is meticulously produced in accordance with the customer’s specific demands and specifications.

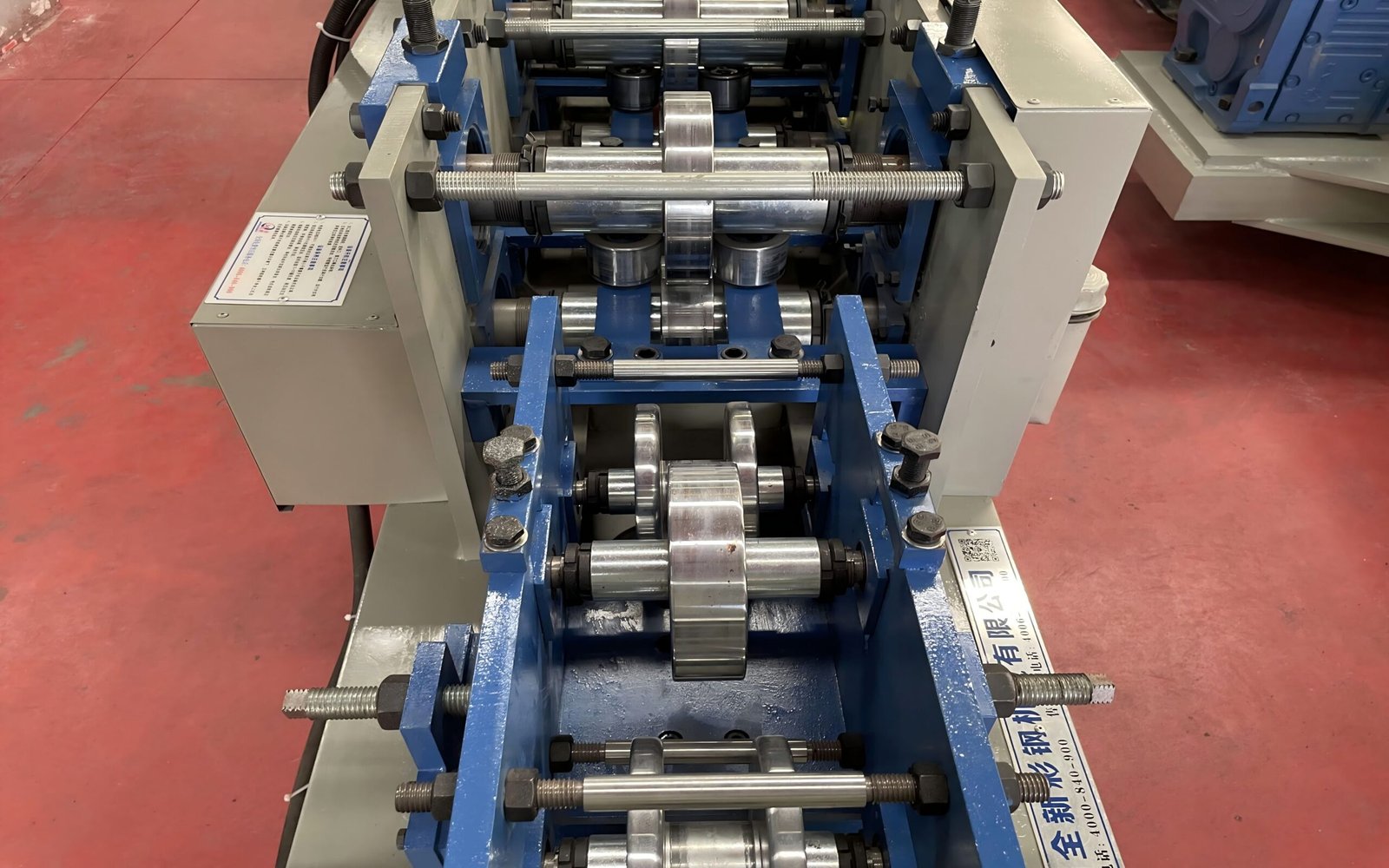

Machine Components

1.Main machine

1)Material thickness from 0.8mm to 1.5mm;

2)Roller shafts 45# steel,diameter of φ80mm;

3)Driver motor 15KW motor,with frequency speed control;

4)Forming station 12;

5)Forming speed 20m/min, making it an ideal choice for high-speed production lines.

2.Decoiler

1)Manual decoiler,manually control the inner bore shrinkage and stopping of the steel coil;

2)Feeding width up to 500mm;

3)Coil inner diameter470mm ± 30mm;

4)Capacity up to 3 tons.

3.Rollers

1)Material is GCr15 bearing steel;

2)Machining on CNC lathes;

3)Subjected to rigorous heat treatment processes;

4)Highly resistant hard-chrome coating.

4.Post Cutter

1)Material is mold steel Cr12;

2)Undergoes heat treatment,precision cutting.;

3)Cutter frame boasts 30mm steel plate;

4)Powered by a 5.5KW hydraulic motor,range of 0-16Mpa.

Video

Reviews

There are no reviews yet.