C Purlin Machine

Features of C purlin machine

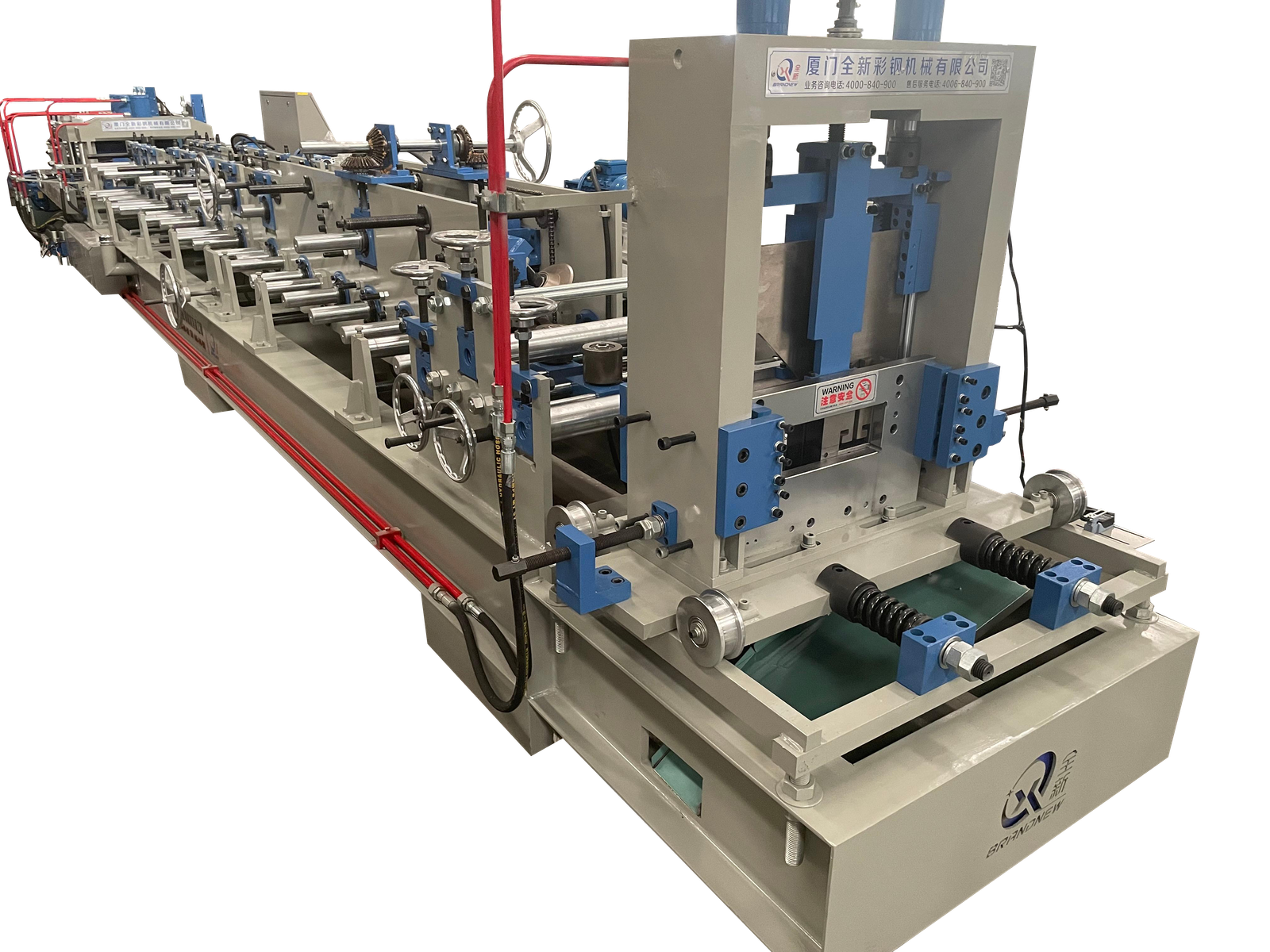

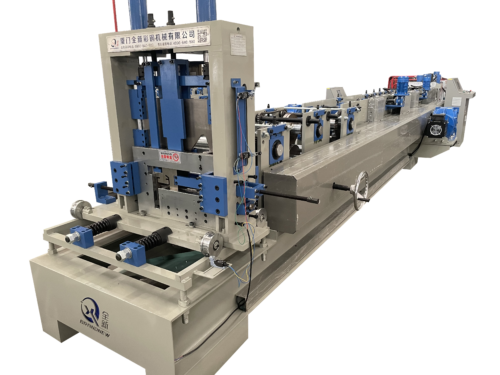

The C25025 C purlin machine is ideal for small C – profile production. It has 13 roll – forming stations with Cr12 vacuum – heat – treated rollers, ensuring high performance and reliability.

Adjustable in size, it can handle widths from 50 – 250mm and thicknesses from 1.0 – 2.5mm. Despite its compact size, it offers great versatility. Engineered with precision, it’s a top – notch investment for optimizing production and outperforming competitors.

| Machine Quick Details | |

| Model number: C25025 | Condition: New |

| Type: C Purlin machine | Brand Name: Beenew |

| Max Production Capacity: 30m/min | Power(W): 15.0KW |

| Warranty: 2 years | Place of Origin: China |

Work Flow

Decoiler — Feeding and leveling —-Main roll forming — Hydraulic punching and cutting — Product support frame

Advantages of the automatic size-change type C channel machine

1. It is capable of manufacturing various purlin sizes ranging from C50 to C250 without the necessity of replacing rollers or spacers.

2. There is no requirement to change the cutter when dealing with different purlin sizes.

3. The operation is simple and straightforward, and the cost for maintenance is relatively low.

4. It enables infinite sizing, meaning any size within the machine’s applicable range can be produced, which contributes to material savings.

5. There is an optional function to punch holes at any position on both the web side and the flange side of the purlin.

Main components

1. Hydraulic Decoiler

Un-coiler Type: Automatic fasten and loosen

Weight capacity: 5T

2. Feeding and Leveling Device:

This device serves the purpose of flattening the material.

3.Main roll forming machine

Driving mechanism: Chain – driven

Maximum forming speed: 30 meters per minute

Roller configuration: Approximately 13 sets of rollers

Roller material: Utilizes Cr12 mould steel

Lower roller diameter: Roughly 360 millimeters

Shaft details: The shafts of the rollers undergo double – grinding on a grinding machine. The diameter of the main shaft ranges from ø70 – 55 mm (subject to the final design)

Main shaft material: Made of 40Cr

Size – changing mode: Available in automatic or semi – automatic options

4. Hydraulic Punching & Cutting

Punching Type: Hydraulic punching (applied before roll forming)

Cutting Type: Hydraulic cutting (suitable for 100–300mm width range)

Cutting Material: Cr12MoV high-performance alloy steel

Hydraulic Motor Power: 5.5 kW

Hydraulic System Pressure: 12–16 MPa

5.Product track —3 set

6. PLC Control System

Automated Control: Manages production quantity, punching length, and cutting length with precision.

Operational Safety: The machine is automatically paused during punching and cutting processes.

Measurement & Counting:

Automatic length measurement (precision: ±2mm).

Real-time production quantity tracking.

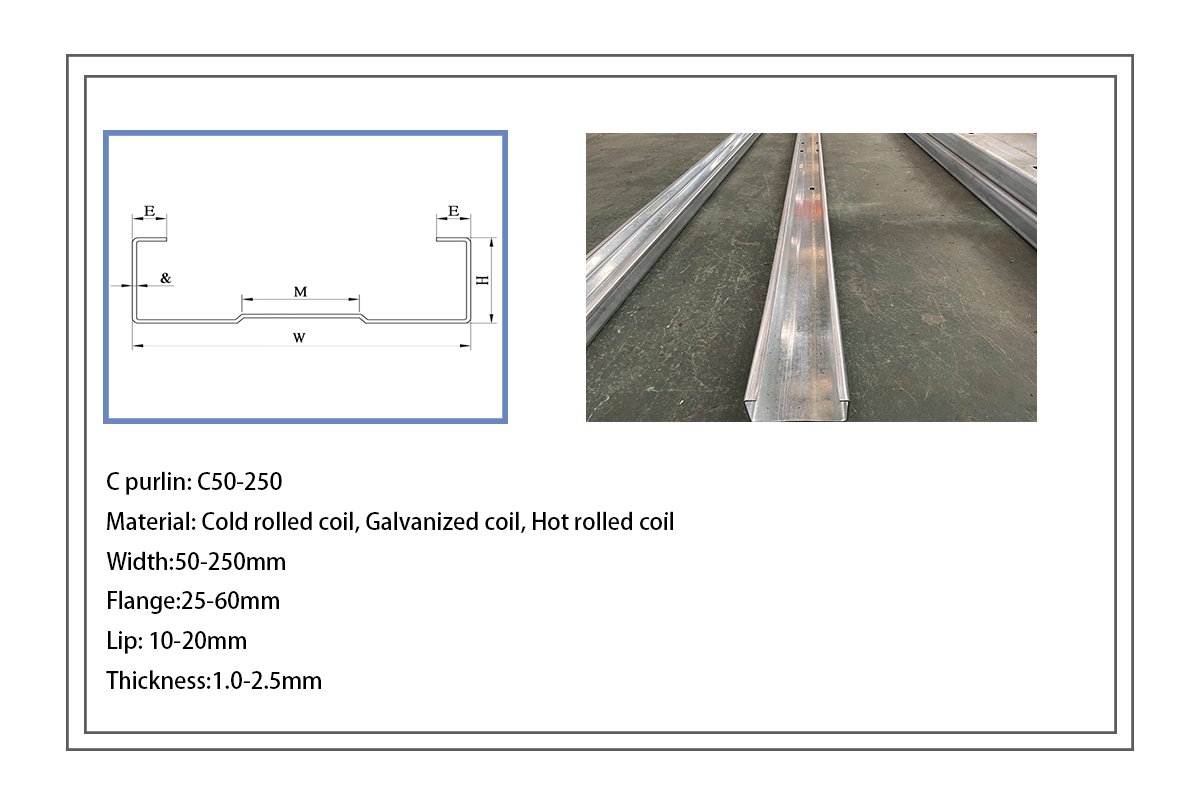

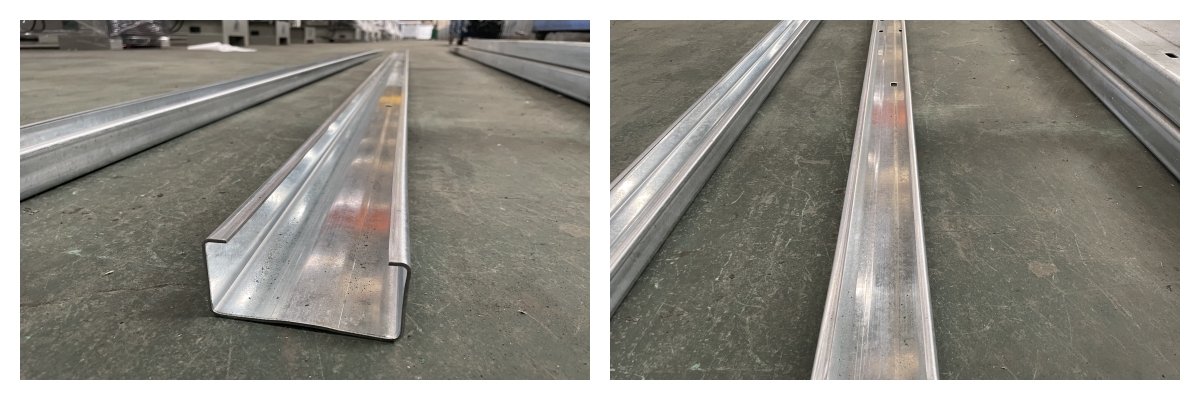

7.Product-C purlin

Our factory

Why Choose us:

– Boasting 28 years of expertise in manufacturing CZ purlin roll formers.

– Offering products with competitive prices and high – quality standards.

– Providing a 2 – year complimentary warranty.

– Ensuring a rapid response in after – sales service.

– Capable of automatically adjusting web size from 100mm to 300mm within 5 minutes.

– Open to customization according to clients’ specific needs.

– Featuring user – friendly operation and straightforward maintenance.

– Having self – developed post cutters, where a single blade can cut all sizes of final products.

Reviews

There are no reviews yet.