Decoiler

Decoiler, is a mechanical device that performs a series of processing operations on metal sheets, such as uncoiling, leveling, shearing, etc. It is mainly composed of uncoiling mechanism, lifting trolley, hydraulic system, infrared measurement and accessories, and can process metal sheets efficiently.

This sheet metal decoiler for sale is specialized equipment for processing sheet metals. Decoiler uncoiler machines are used for uncoiling steel coils and uneven plates. According to different configurations, the steel decoiler can be composed of an uncoiling, leveling, shearing production line, and other plate product production lines. It is applicable to industries such as machinery, vehicles, metal products, household appliances, steel structures, and decoration. Welcome to contact the decoiler manufacturer – Beenew Machinery. We have horizontal decoilers, steel decoilers, and manual decoiler machines available for sale!

The decoiling machine is an essential equipment in the welded pipe production line and cold roll forming line. Its function is to feed the steel head into the flattener by rotating it with the help of the stamping machine. Therefore, the normal operation of the decoiler machine is crucial to the entire production line. In recent years, the structure of the decoiling machine has been continuously optimized and improved, enhancing the performance of the decoiler.

Our company is a leading decoiler machine manufacturer, offering the highest – quality uncoilers for sale. Our machines, featuring excellent uncoiler designs, are engineered to deliver the highest levels of performance, efficiency, and reliability. Our horizontal decoilers, steel decoilers, and manual decoilers are built to last, with sturdy construction and the latest technological advancements, ensuring the best possible outcomes.

The Function of Sheet Metal Decoiler

The main shaft of this sheet metal decoiler that is currently available for sale serves two key functions. Firstly, it is responsible for driving the steel coil to rotate. This rotation is essential for the continuous unwinding of the steel coil during the production process. Secondly, it provides tensioning support for the steel coil.

The tensioning function is typically achieved by an oil cylinder or a cylinder that is mounted in conjunction with the spindle. This cylinder exerts pressure to push the inclined side of the relevant component, ensuring that the steel coil remains properly tensioned as it is being uncoiled.

As for the rotation function, it is usually carried out when a motor drives the spindle to rotate through a reducer. This coordinated mechanism ensures smooth and controlled rotation of the steel coil.

It’s important to note that the oil cylinder or cylinder installed on the spindle will rotate together with the spindle. One end of this cylinder is connected to the working medium pipeline, while the other end of the pipeline is linked to either a hydraulic station or a solenoid valve. This connection is crucial for the proper operation and control of the tensioning and overall functioning of the decoiler.

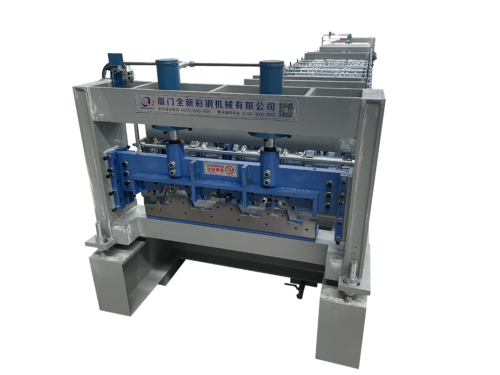

Detail

This is one of our machines. Please contact us if you need customization.

1.Expanding type : Automatic unwinding and turning, hydraulic coil expansion;

2.Loading capacity :7T;

3.Inner diameter :550 mm;

4.Hydraulic pressure :12 MPa;

5.Motor Power : 5.5 kW;

6.Coil car : not included

Functional Features of the Sheet Metal Decoiler for Sale

1. Inlet – End Functions

– The decoiler machine, positioned at the front end of the unit’s inlet, serves two main functions. Firstly, it performs upper – decoiling operations while ensuring that the strip maintains post – tension. This is crucial as it guarantees the smooth unwinding of the metal strip and proper tension levels, which are essential for the integrity of the subsequent manufacturing processes.

– Secondly, it enables the automatic alignment of the strip under central control. This precision alignment ensures that the strip is accurately positioned, allowing for seamless operation of the entire production unit.

2. Uncoiling Set – up in Different Production Units

– In a typical continuous return and color – coating unit, two uncoiling machines are installed. These machines work in an alternating pattern when uncoiling. This alternating operation creates the necessary conditions for the continuous production of the downstream equipment in the unit, ensuring an uninterrupted workflow.

– In a cut – in line or roll – forming line, a decoiler is also an essential component. The strip tension in the inlet section is jointly determined by the decoiling machine and the numbered 1 – tension roller set of the unit. This combined action ensures the stability of the strip during the initial processing stages.

3. Mechanical Structure and Operation

– The body of the uncoiler machine features a welded box structure. A frequency – conversion speed – regulating motor powers the main shaft. After passing through a gearbox for deceleration, the motor provides the primary power for the decoiler. The main shaft of the uncoiling machine is hollow and is supported on the gearbox body by two bearings. Between these bearings, a transmission – power gear is installed.

– The gearbox is lubricated through forced lubrication, and the closed – loop lubrication system is equipped with two constant – speed motors. This setup ensures the smooth operation and long – term durability of the mechanical components.

– The main shaft has a cantilever structure. For heavy – duty decoilers, a support arm is provided. When uncoiling, the front end of the support arm is supported by an outer support bearing. This arrangement helps maintain the rigidity and stability of the decoiler, especially when handling large or heavy steel coils.

– The uncoiling movement axis is connected to four fan – shaped plates via four bevel – gear grooves on four end faces. Each fan – shaped plate is prevented from axial movement by a radial side at the end, but it can expand and contract radially. The end of the drum shaft is connected to a rotating oil cylinder. The piston rod of the cylinder drives the front four – edge axis to move axially through the hollow rod in the center of the drum shaft, thereby enabling the radial expansion and contraction of the fan – shaped plate. The nominal diameter of the reel can be increased by adding four fan – shaped plates.

– The frame of the decoiler can be moved along the guide rail of the frame, driven by a hydraulic cylinder, and its central position can be precisely controlled. This adjustability allows for better adaptation to different production requirements.

– To further enhance the stability of the drum, a support arm device is designed on the head of the drum. When a steel coil is on the drum, the support arm is driven by the oil cylinder to support the head of the drum. In normal circumstances, the support arm retracts to avoid interfering with the winding of the steel coil.

4. Optional Coil Cart Feature

– Some sheet metal decoilers come with a coil cart. The coil cart offers the advantage of quick coil change. Its most significant feature, however, is that it eliminates coil damage that could occur during forklift loading and unloading due to coil collisions. Unlike other decoilers, there’s no need to use wood to block the cart. It also facilitates easy loading and unloading of coils, requiring only a few operators. The coil cart extends from the mandrel, eliminating the worry of scratching the mandrel during coil loading. A 1/2HP motor with a scissor – action lift can extend a full coil to the mandrel.

5. About Beenew Machinery

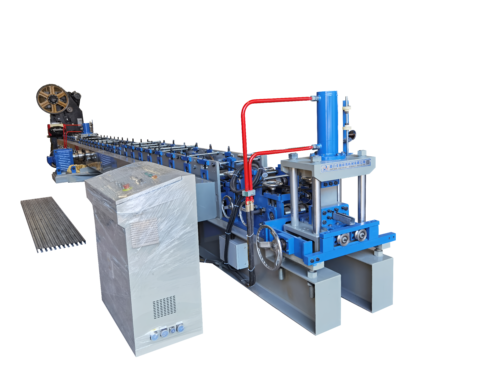

– Beenew Machinery is a professional manufacturer and exporter of a wide range of standard and non – standard cold roll – forming equipment and tube mill equipment. As one of the leading decoiler machine manufacturers in China, the company also provides auxiliary equipment for cold roll – forming lines and tube mill/pipeline.

– This auxiliary equipment includes Decoilers, Recoilers, Coil Penders, Slitting Lines, Cut – To – Length Lines, Stackmasters, Sheet Metal Shears & Metal Cutting Machines, Coil Embossing Machines, Punching Machines & Curving Machines, Automatic Roof Seaming Machines, Logo Printing Machines, Accumulator Flying Saws, Output Stacking Systems, Autom atic Packing Machines, and more.

– Both domestic and international customers are welcome to reach out to us for more information. Whether you’re interested in a specific piece of equipment or need comprehensive solutions for your production line, our team is ready to assist.

Reviews

There are no reviews yet.