C Channel Making Machine

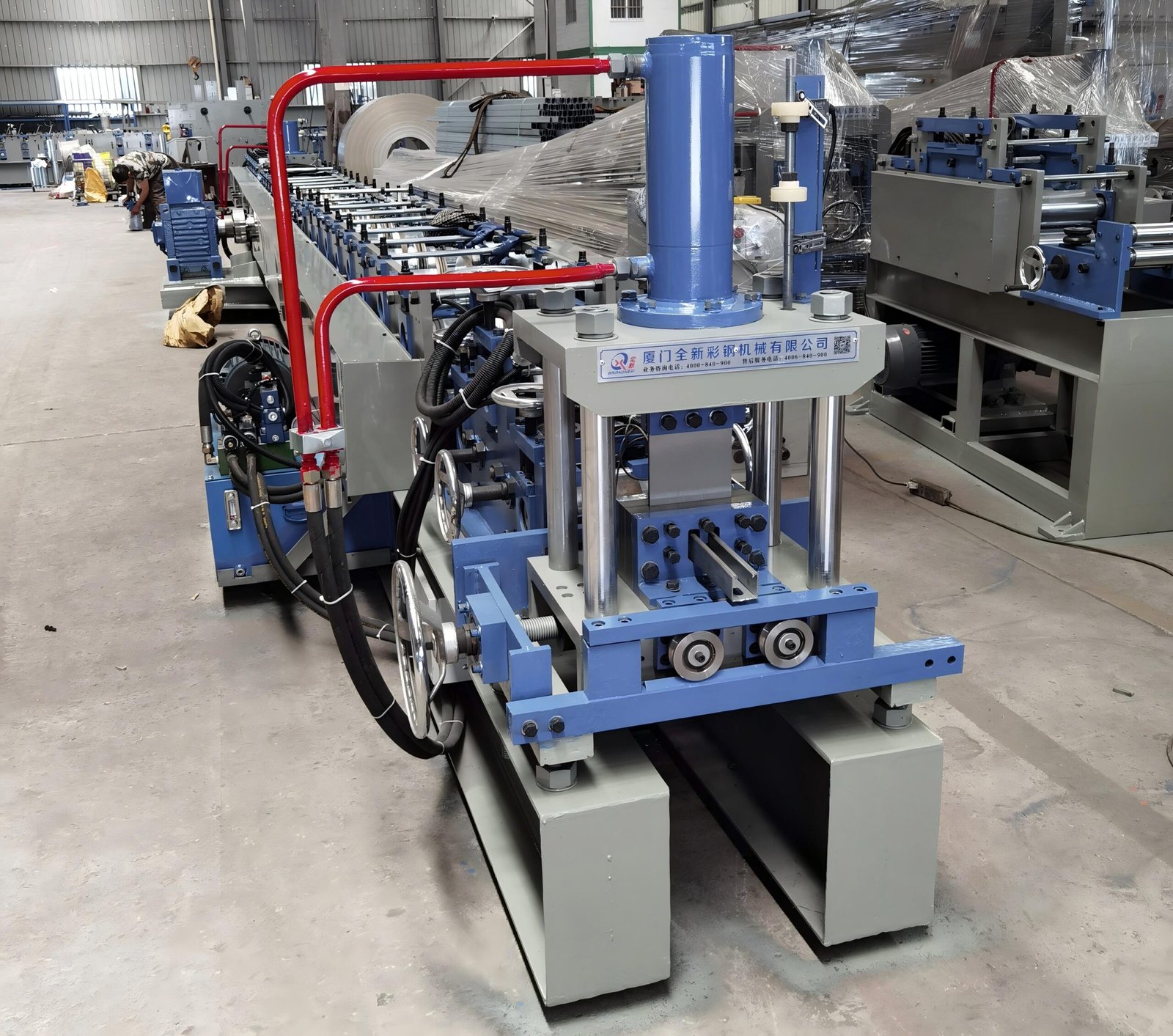

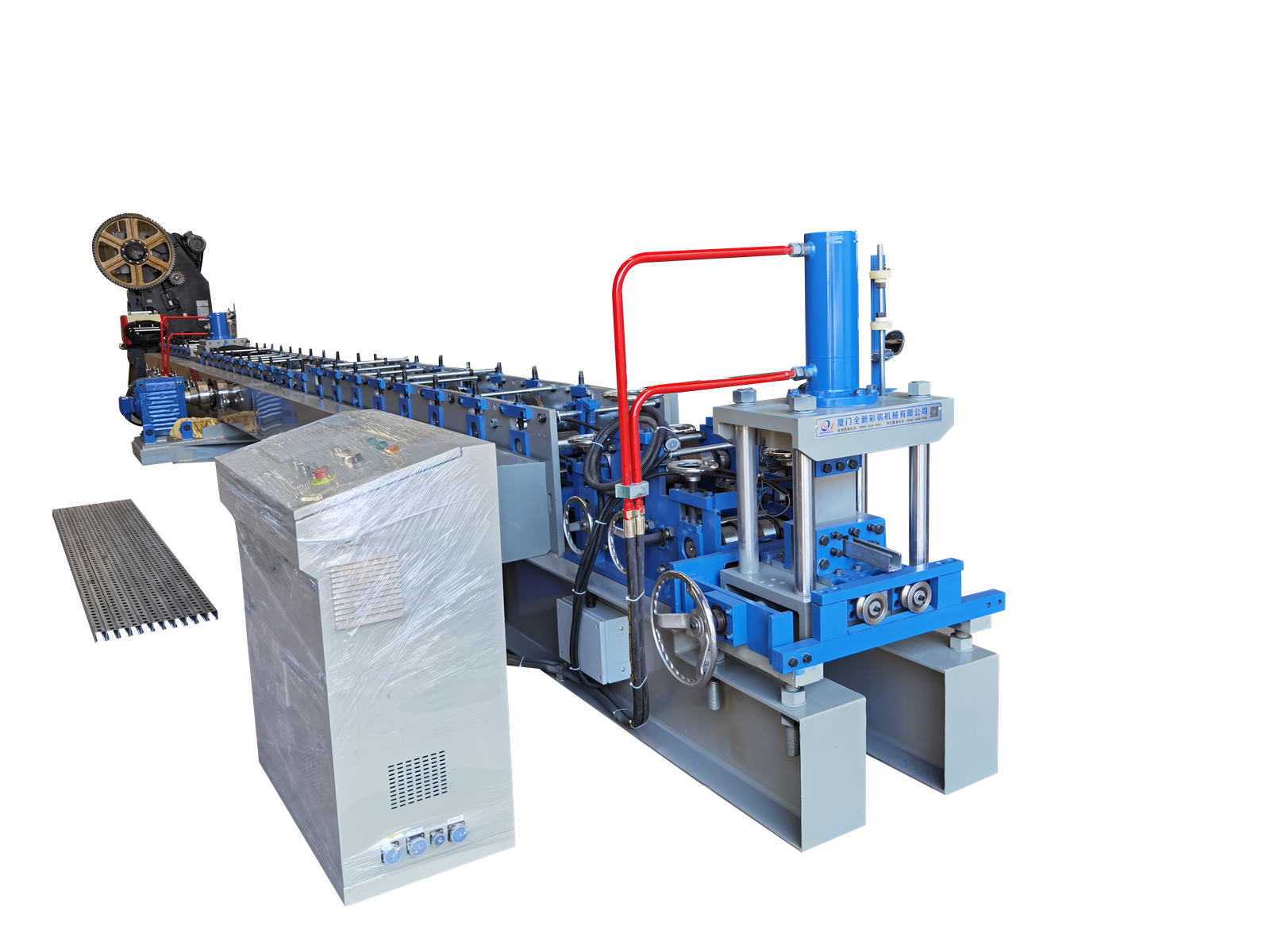

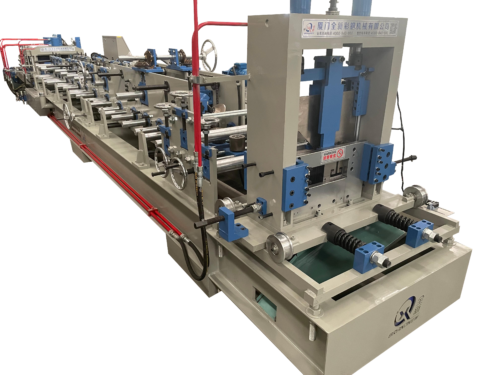

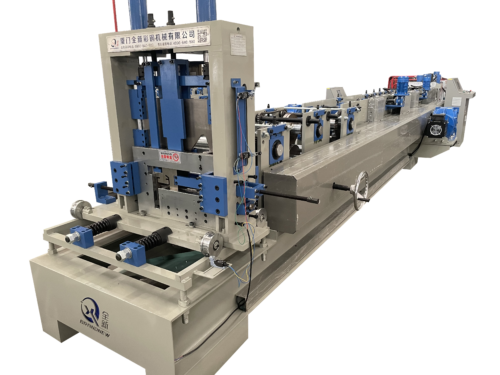

Main M/C of Strut Channel Roll Forming Machine

Uncoiler

5 Ton Manual Un-Coiler

Coil strips width: 200-500 mm

Coil Inner-diameter: 480 mm to 560 mm

Max.capacity: 5 Ton

Structure: Steel plate and Beam Welded

Function: Supporting and uncoiling the steel strips and then input into the machine

Feeding And Leveling Used in C Channel Machine

Feeding type: Manual Adjustable

Material Width range:200-600 mm

Feeding and guiding roller diameter: ¢75 mm

Roller material: 45 # Steel With Quenched Treatment HRC 48-52, surface chromed

Leveling roller: Upper 3, underneath 4 (totally 7 rollers)

leveling roller: 45 # Steel With Quenched Treatment HRC 48-52, Chromed

Diameter of leveling shaft: ¢75 mm

Material of leveling shaft: 45# steel hardening and tempering

Roll Forming Mill

Material thickness: 1.5-4 mm

Main motor power:30 KW

Forming speed: 20m/min(not include cutting time)

Quantity of stands: 26 stations

Shaft material and diameter: ¢75 mm,45# steel

Material of forming rollers: GCR 15, tempered and chromed 0.05mm thickness

Tolerance: +/-2 mm

Type of drive: 2.0 inch single chain

Total weight: About 10 Tons

The sizes of web and flange can be adjustable

Hydraulic Cutting Device

Cutting type: Hydraulic cutting

Cutting power: 11 KW

Working pressure: 16 Mpa

Cutting motion:Roll Forming Part Is Stop When Cutting

Material of Cutting Mould:Cr12 Steel With Quenched Treatment HRC 60-62

Cutting Length and Quantity: Clients Set Length and Quantity on the PLC Touch Screen

Tolerance of length: +/-2 mm

C Purlin Machine Hydraulic Station

Hydraulic power: 11 KW

Working pressure:16 Mpa

Hydraulic oil: 46# hydraulic oil

Color:blue (or depend on per requirement)

Controlled System of C Channel Machine

The worker input the length and quantity of the product through touch screen, total 20 groups, the touch screen will show the working status of the machine.

Adopt Aviation Plug for easy connection

Computer Control System: Panasonic or siemens

Encoder and limit switch: Omron Brand

Frequency Converter: Yaskawa

Touch Screen: MCSG or Siemens

Controlled System Power: Overload Protection

Pressure Of Hydraulic Station: ≧12 Mpa

Current: 380 V Direct Current, 60 Hz, 3 Phase

Product samples

Reviews

There are no reviews yet.