Corrugated Iron Making Machine

Corrugated metal roofing sheets are highly durable due to their distinct corrugated shape. This natural shape provides them with a structural edge compared to other panels made from the same material. Color – coated roofing sheets have the ability to gradually conceal minor flaws caused by weather or impacts.

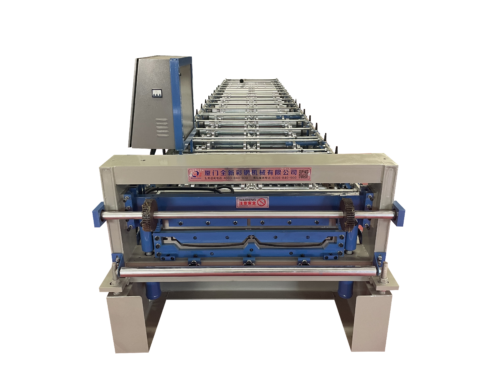

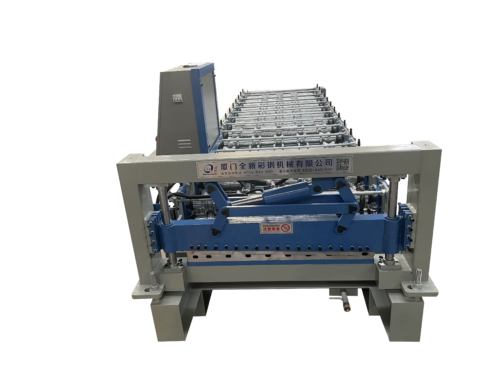

The Beenew Corrugated Roll Forming Machine is purpose – built for rolling galvanized, pre – painted, and Galvalume steels into corrugated roof sheets. It is engineered to efficiently transform these raw materials into the desired corrugated roofing products, meeting the specific requirements of the roofing industry.

Small corrugated metal profiles are both durable and lightweight. Currently, we’re devoting our efforts to developing the optimal machine for manufacturing corrugated or corrugated roof sheet machines. These machines are highly sought – after for constructing roofs and sides of buildings. In recent times, corrugated metal panels have witnessed a surge in popularity as modern and contemporary choices for roofing and siding. They offer a combination of practicality, such as durability and cost – effectiveness, along with an aesthetically pleasing appearance that suits the architectural trends of today’s buildings.

Beenew, as a manufacturer of Corrugated Roll Forming Machines, provides European Style Corrugated Roof Sheet Roll Forming Machines or Corrugated Roof Sheet Roll Forming Machines with CE certification. These machines are capable of producing original corrugated sheets and metal roof tiles. The corrugated metal roofing and corrugated metal wall panels are widely used. They give a unique and customized appearance to the roofs of numerous restaurants, various establishments, and other commercial buildings, enhancing the overall aesthetic and functionality of these structures.

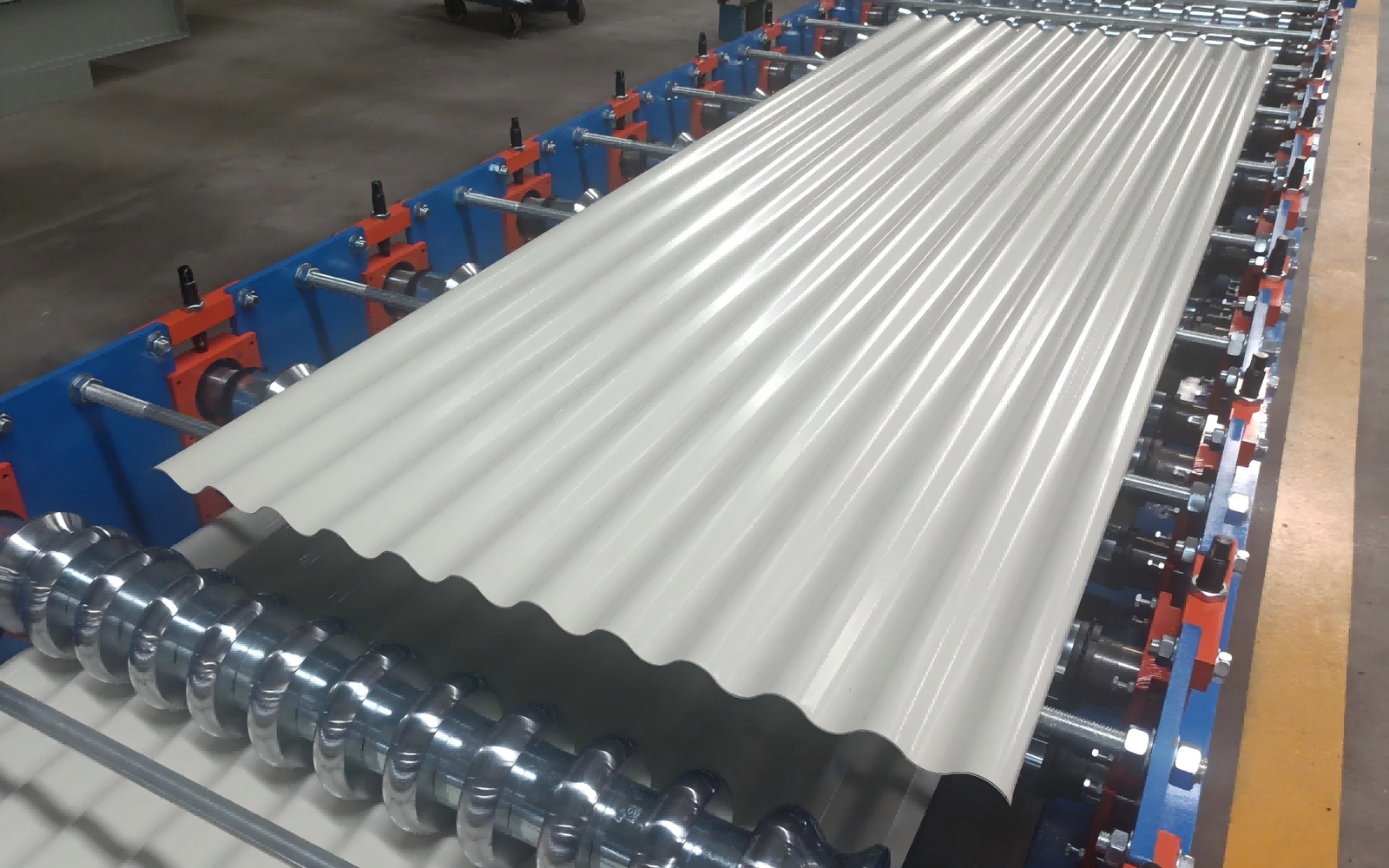

Product samples

Furthermore, there is a 2.5mm silo corrugated roll forming machine, also known as the Steel Silo Corrugated Side Panel Roll Forming machine, equipped with a stacking system. This machine is primarily designed for manufacturing steel silo corrugated panels, which are mainly applied as the external wall panels of fabricated steel structure warehouses. Its working process consists of several key steps: a 15 – Ton hydraulic decoiler that unwinds the raw material, a forming machine that shapes the material into the desired corrugated form, servo – tracking cutting to ensure accurate cutting lengths, a belt conveyor for transporting the semi – finished products, and finally, a stacking system for neatly arranging the completed steel silo corrugated panels.

Machine Parameters

Application

Machine Video

Reviews

There are no reviews yet.