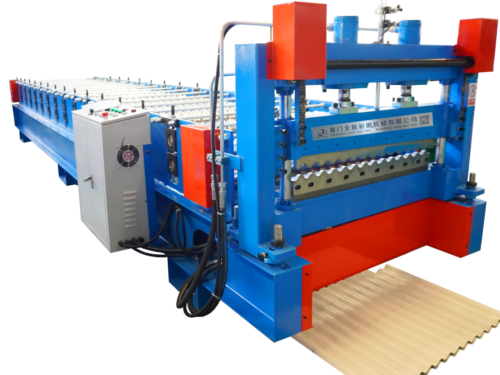

Metal Roof Making Machine

The metal roof making machine production line takes galvanized steel sheets, colored steel sheets of diverse colors, or aluminum sheets as its raw materials.

The products fabricated by this line are applied in constructing the external roof and wall panels of houses, as well as for interior decorative panels or ceilings. They significantly enhance both the aesthetic appeal and the durability of the roofs and walls.

The metal roofing sheet making machine is the optimal equipment for the steel structure and cold forming sectors. It integrates mechanical, electrical, and hydraulic systems. With its high work efficiency, it can operate automatically, saving both time and labor.

Based on the thickness and quality of the plates in use, the metal roof making machine can punch out flawlessly symmetrical waves. The produced items are not only robust and long-lasting but also can be tailored to different needs, providing great flexibility for various construction projects.

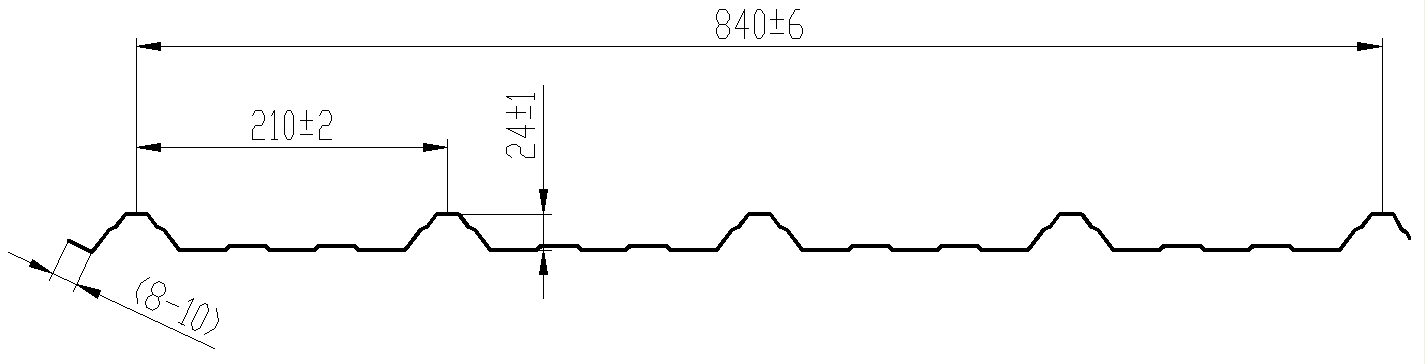

Profile Drawing

Features of metal roof making machine

– Completely automated roof tile production line

– In-line high-speed perforation functionality

– Width that can be flexibly adjusted

– Superior quality roll forming process

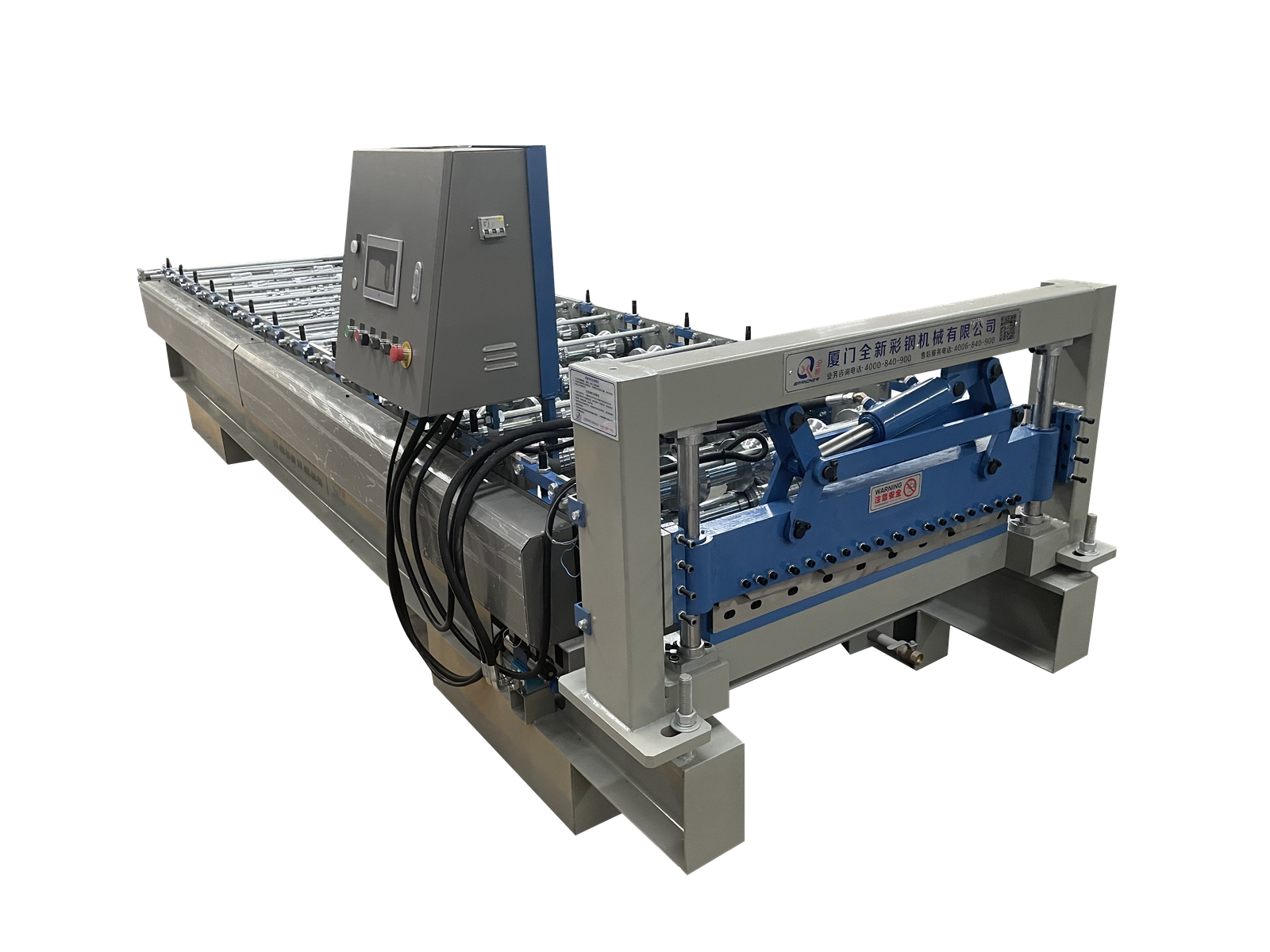

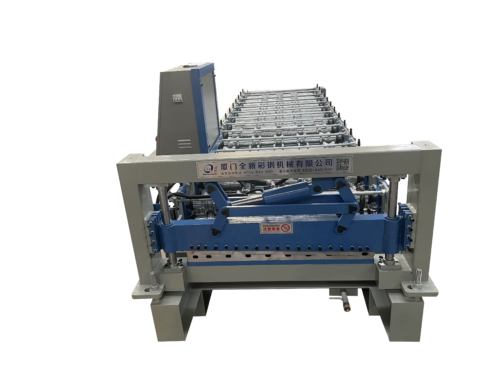

Main Machine

1.Roll stand: 22 stations

2.Driving power: 11KW,chain transmission

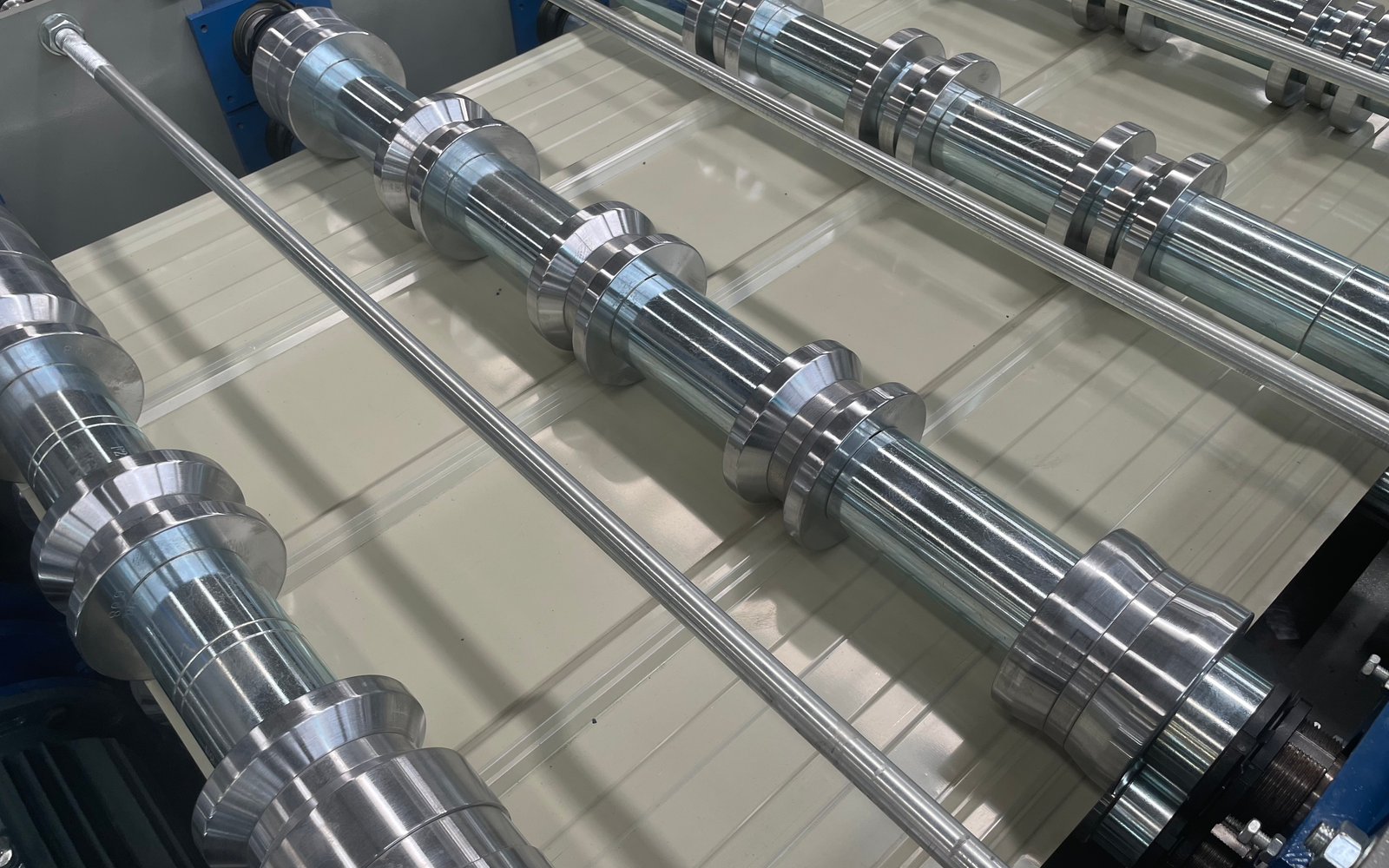

3.Roller Material : 45# steel finishing

5.The roler 45# steel fine processing, surface hard chrome plating and brushed polishing

5.Shaft Material: 45# steel finishing

6.Shaft diameter: φ80mm

7.Machine frame: welding by 396 x 199mm H shape steel

Electric Control System

1.Control system: PLC (Customers can specify the brand)

2.Operation platform: touch screen+press button

3.Main motor: AC frequency conversion electric motor

Main Components

1. Decoiler

2. Feeding Guidelines

3. Manual Slitting Device

4. Roll Forming System

5. Hydraulic CuttingMachine

6. Control System

7. Product Rack

FAQ

Q: What about your Warranty?

A: Our warranty period is 24 months. During this time, all parts that get damaged due to quality issues will be replaced free of charge.

Q: How long is your delivery time?

A: It will be within 50 to 60 days after we receive the advance payment. Some standard machines are available in stock and can be shipped out at any time.

Q: What are your payment terms?

A: A 30% deposit needs to be paid before the production starts, and the remaining balance should be settled after the inspection and confirmation before the shipment.

Q: How about your installation and training services?

A: If the buyers come to our factory for inspection, we will offer face-to-face training on installation and operation. If not, we will provide a manual and videos to demonstrate how to install and operate the machines.

Q: What kind of after-sale service do you provide?

A: We offer 24-hour online service for our customers.

A. The seller will conduct free debugging of the machines in China, and the seller will bear the domestic transportation expenses of the technical personnel in China. When the technical staff go to the buyer’s location to debug the machines, the buyer should cover the accommodation and transportation expenses for these technical staff.

B. If the buyer sends their people to receive the operation training provided by the seller, during the training period, the seller will be responsible for the accommodation and transportation expenses of the buyer’s personnel.

About Beenew machinery

Beenew Machinery ranks among the top manufacturers of sheet metal processing machines and roll forming machines in China.

Our most prominent products are roll forming machines. This range encompasses the Multi Size U baffle ceiling roll former, the Drywall studs and tracks roll forming line, the Multi width shelf panel making machine, High speed C / Z / U / angle channel roll forming machines, the Light gauge steel framing roll forming machine, the Roof tile roll forming machine, the Bed frame forming & welding machine, as well as various other customized roll forming machines tailored to different customer needs.

Established in 1997, Beenew Machinery boasts over 28 years of rich manufacturing experience. It has successfully earned the trust of customers worldwide. Our clientele includes customers from countries such as Russia, India, Egypt, Saudi Arabia, and the United Arab Emirates.

Reviews

There are no reviews yet.