Steel Stud Roll Forming Machine

Introduction

In today’s construction and energy fields, the processing and application of steel plays a vital role. As a key industrial equipment, the channel roll forming machine has demonstrated strong production capacity and wide applicability.

The channel roll forming machine is like a skilled craftsman who can produce a wide range of profile products. From solid columns to precise tracks, to commonly used channel steels and uniquely shaped C/U/T profiles, it can easily handle them. These different types of profiles play an indispensable role in many aspects such as construction, industrial manufacturing and energy.

Among them, a special channel roll forming machine has a special mission in the field of solar photovoltaics – mainly used to produce tracks for solar photovoltaics. In the construction of solar photovoltaic systems, these tracks are key components to ensure the stable installation and efficient operation of photovoltaic modules. They are like the veins of the solar photovoltaic system, providing solid support for photovoltaic modules, allowing sunlight to be accurately converted into electrical energy, and providing clean and sustainable energy for people’s lives and production.

And these various types of profiles produced by the steel column forming machine have a wide range of application scenarios. In the field of construction, they are often used as vertical frames for non-load-bearing wall systems. Imagine that in a modern high-rise building, the non-load-bearing wall system not only serves as a space divider, but also adds flexibility and beauty to the entire building. As vertical frames, these profiles are like the skeleton of the building, silently supporting the wall to ensure its stability and safety.

In the installation of ceilings, these profiles also play an important role. They provide a stable support structure for the ceiling, allowing the ceiling to be suspended flat on the top of the building, creating a comfortable and beautiful environment for the indoor space. At the same time, in the application of gypsum board brackets, they reliably fix the gypsum board with their sturdy characteristics, ensuring the quality and effect of interior decoration.

In the booming photovoltaic system, these profiles have become an ideal choice for brackets. With the growing global demand for clean energy, the number of solar photovoltaic systems installed is increasing day by day. Brackets made of these profiles can adapt to various complex terrain and climatic conditions, ensuring that photovoltaic modules always maintain the best working condition and maximize the conversion of solar energy into electrical energy.

As a leader in the industry, Beenew is well aware of the diverse needs of customers for profile forming machines. Therefore, based on the profile design drawings provided by customers, Beenew can give full play to its professional advantages and customize forming machines for profiles of various sizes. Whether it is a small construction project or a large industrial manufacturing demand, Beenew can accurately meet customer requirements.

In addition, Beenew is also committed to technological innovation and continuously improving the performance of forming machines. Its forming machines can be designed as high-speed systems, which greatly improves production efficiency and meets the needs of large-scale production. In terms of rapid stamping, it can achieve accurate and efficient stamping operations to ensure the quality and precision of profiles. The rapid cutting system further optimizes the production process, making the cutting process faster and more accurate, reducing material waste and improving production efficiency.

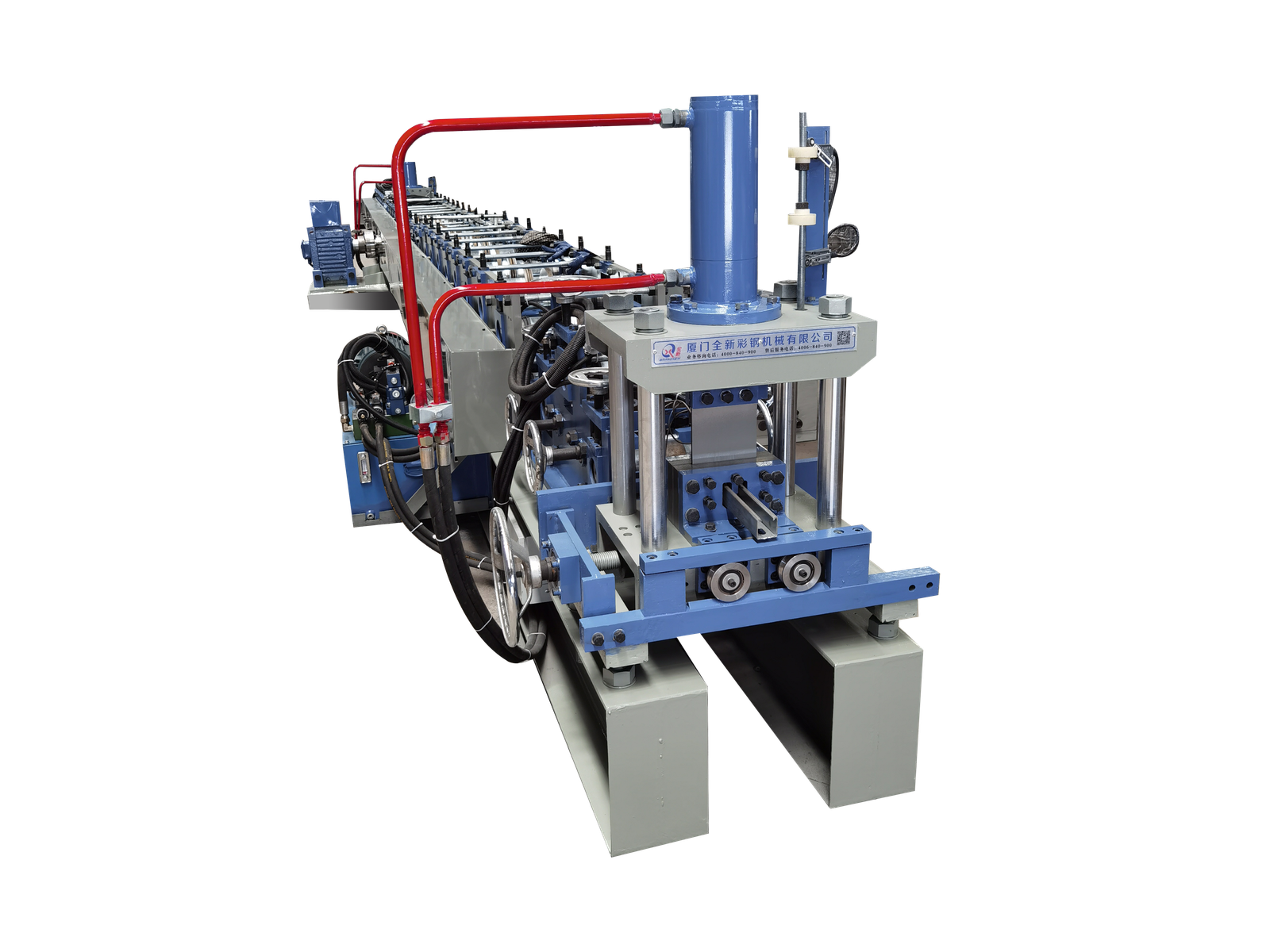

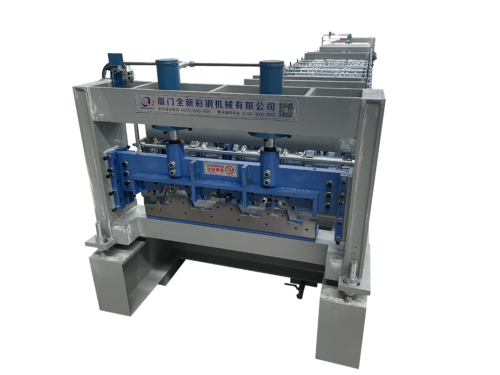

Main M/C of Steel Stud Roll Forming Machine

Uncoiler

5 Ton Manual UnCoil stripser

Coil strips width: 200-500 mm

Coil strips I.D: 480 mm to 560 mm

Max.capacity: 5 Ton

Structure: Steel plate and Beam Welded

Function: Supporting and uncoiling the steel strips and then input into the machine

Feeding And Leveling Device

Feeding type: Manual Adjustable

Material Width range:200-600 mm

Feeding and guiding roller diameter: ¢70 mm

Roller material: 45 # Steel With Quenched Treatment HRC 48-52, surface chromed

Leveling roller: Upper 3, underneath 4 (totally 7 rollers)

leveling roller: 45 # Steel With Quenched Treatment HRC 48-52, Chromed

Diameter of leveling shaft: ¢75 mm

Material of leveling shaft: 45# steel hardening and tempering

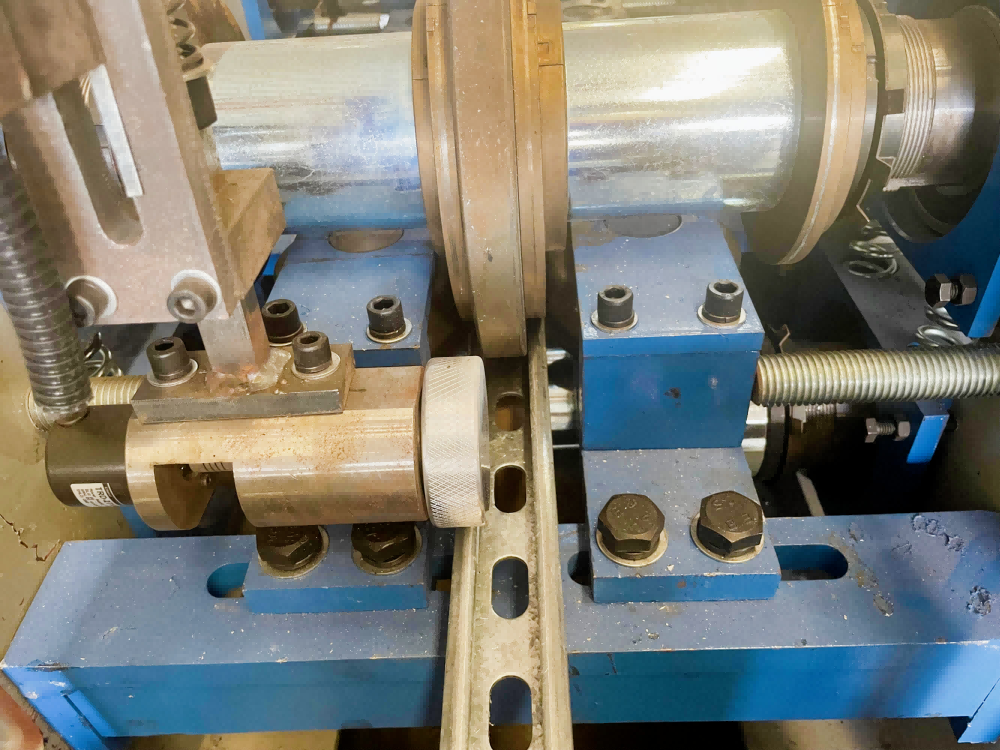

Roll Forming Machine

Material thickness: 1.5-4.0 mm

Main motor power:22 KW

Forming speed: 20m/min(not include cutting time)

Quantity of stands: 24 stations

Shaft material and diameter: ¢75 mm,45# steel

Material of forming rollers: GCR 15, tempered and chromed 0.05mm thickness

Tolerance: +/-2 mm

Type of drive: 2.0 inch single chain

Total weight: About 10 Tons

The sizes of web and flange can be adjustable

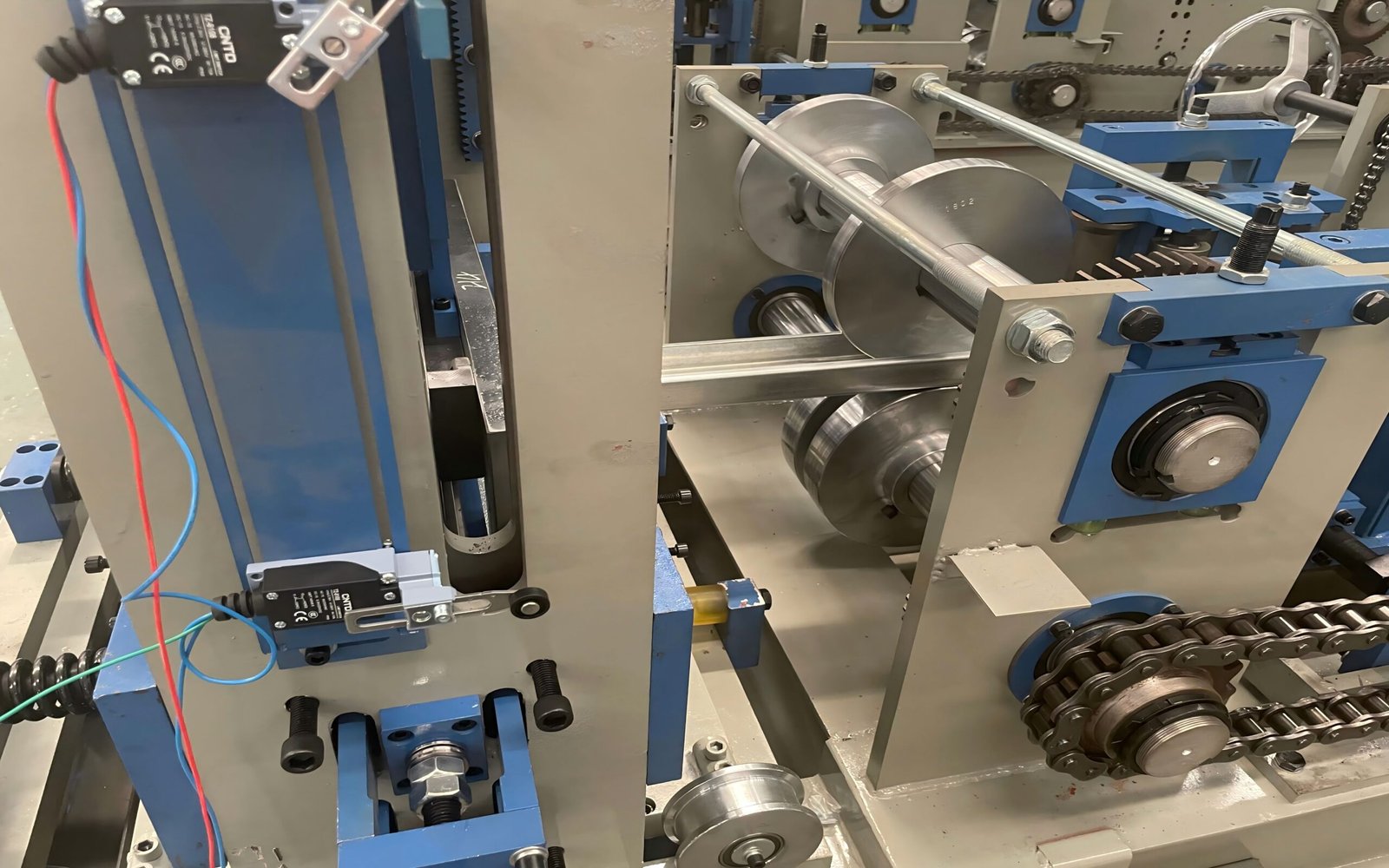

Hydraulic Cutting Device

Cutting type: Hydraulic cutting

Cutting power: 11 KW

Working pressure: 16 Mpa

Cutting motion:Roll Forming Part Is Non-stop When Cutting

Material of Cutting Mould:Cr12 Steel With Quenched Treatment HRC 60-62

Cutting Length and Quantity: Clients Set Length and Quantity on the PLC Touch Screen

Tolerance of length: +/-2 mm

C Purlin Machine Hydraulic Station

Hydraulic power: 11 KW

Working pressure: 16 Mpa

Hydraulic oil: 46# hydraulic oil

Color:blue (or depend on per requirement)

Controlled System of Stud Roll Forming Machine

The worker input the length and quantity of the product through touch screen, total 20 groups, the touch screen will show the working status of the machine.

Adopt Aviation Plug for easy connection

Computer Control System: Panasonic PLC or siemens

Encoder and limit switch: Omron Brand

Frequency Converter: Yaskawa

Touch Screen: MCSG or Siemens

Controlled System Power: Overload Protection

Pressure Of Hydraulic Station: ≧12 Mpa

Current: 380 V Direct Current, 60 Hz, 3 Phase

Product samples

Reviews

There are no reviews yet.