Purlin Roll Forming Machine

General Overview

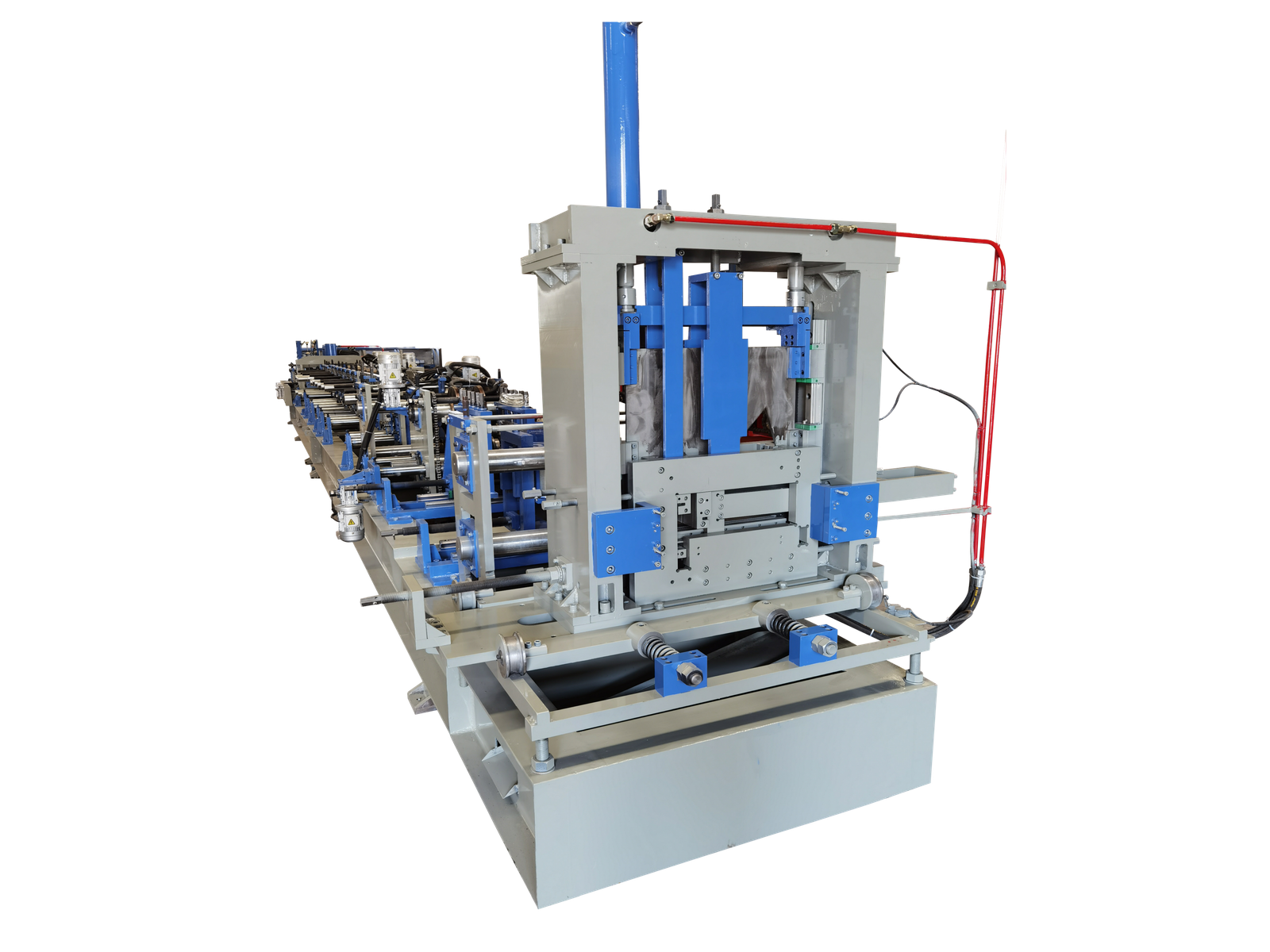

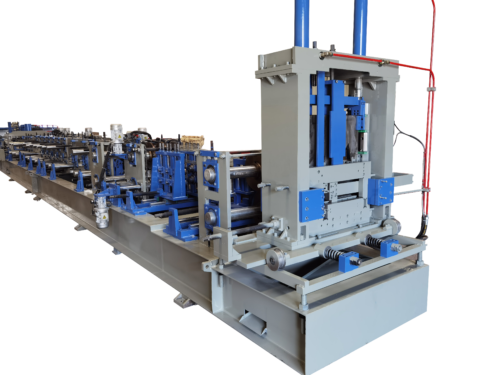

The Fully Automatic High Speed CUZ Purlin Roll Forming Machine with Stacker manufactured by Beenew Machinery is ingeniously engineered. It is specifically tailored for the rapid production of C, U, and Z-shaped products through fly-cutting at high speeds, and it operates in a fully automated manner, integrated with an automatic stacking mechanism.

Distinct from the hydraulic punching machine and the automatic purlin stacking machine, the primary roll forming machine employs a non-stop fly-cutting technique. This enables it to maintain continuous production at full capacity, ensuring seamless operation. In practical terms, it can achieve an impressive actual production speed of up to 40 meters per minute.

Purlin Roll Forming Machine Main Components

1. Hydraulic Uncoiler with Coil Car Or Manual decoiler

2. Flattening Station

3. Punch Station

4. Main Roll Forming Line

5. Fly Cutting(Optional)

6. Power Supply & Control System

7. Roller Conveyor, Auto-Stacker(Optional), Chain Conveyor

Work flow

Uncoiler – Leveling Station – Punch Station – Main Roll Forming Line – Fly Cut(Optional) – Auto Stacker(Optional)

Raw Material Specifications

Material Categories: Hot – rolled steel coils and galvanized steel coils are applicable.

Metal Yield Strength Range: The yield strength of the metal used ranges from 235 MPa to 550 MPa.

Steel Thickness: The thickness of the steel is specified between 1.5 – 4.0mm.

Purlin Length: The length of the produced purlins can vary from 1.5 to 12 meters.

Hydraulic Uncoiler With Coil Car(Optional)

Expansion and Operation Modes: Features motor – driven uncoiling and turnover functions, along with hydraulic expansion.

Loading Capacity: It has a loading capacity of 5 T.

Inner Diameter Range: The inner diameter of the uncoiler is designed to accommodate coils with a diameter ranging from 470 – 520 mm.

Hydraulic Pressure: Operates under a hydraulic pressure of 12 MPa.

Motor Power: Equipped with a 5.5 kW motor.

Coil Car Provision: Comes with a coil car(Optional).

Leveling Station

Leveling Structure: Comprises 3 upper rollers and 4 lower rollers, supplemented by an additional 2 pairs of pinch rollers.

Feeding Mechanism: Incorporates a feeding shaft and feeding rollers.

Roller Dimensions: The diameter of the rollers is 80/100mm.

Punch Station

Punch Type:Utilizes pre – punch, with holes punched before roll forming.

Punch Stations:There are 3 stations, each capable of punching either single or dual holes.

Punching Mold:The mold is customized to precisely meet specific product requirements.

Die Material:Made of Cr12 alloy steel after quenching.

Main Roll Forming Machine

Roll Stand Configuration: Comprises approximately 22 stations.

Roller Material: The rollers are crafted from GCr15, a high – quality alloy steel.

Main Motor: Equipped with a 45Kw three – phase asynchronous motor.

Transmission Type: Features a gearbox for each stand.

Main Shaft: Made of 40Cr alloy steel with heat treatment.

Machine Frame: The machine frame is welded by iron plates and then undergoes flat planer finish machining.

Size Change Mechanism: Controlled by PLC, the size change process is fully automatic.

Straightening Unit: Consists of 10 sets of special roller straightening units and an additional 4 sets of roller straightening units.

Fly Cutting (Optional)

Type: Hydraulic post – mounted mold cutting, continuous cutting without stopping

Cutter Material: Cr12MOV, with quenching treatment

Cutting Molds: 3 pieces, customized according to customer requirements

Control: PLC – controlled cutting length and number of cut pieces

Power Supply & Control System

Cabinet Quantity: One set. Equipped with an ’emergency stop’ switch for the entire production line.

Operation Platform: Features HMI and buttons, presenting English – language display.

Control System: Adopts Siemens PLC.

Key Components: Key components are from Siemens brand.

Roller Conveyor, Auto-Stacker, Chain Conveyor

Type: Auto – stacking machine for CZU purlins

Purlin Length: Up to 12 meters

Function: Purlins are stacked by an automatic turnover mechanism, and then tallied and aligned in a row as per the programmed quantity requirements.

Other purlin roll forming machine that Beenew machinery made

●C Purlin Machine with Stacking Machine: Discover More

This setup consists of a 5T hydraulic decoiler, leveling machine, single – station punch press, main C purlin roll – forming machine with optional fly cutting, and an automatic C purlin stacker. The machine can reach a top speed of 40m/min even when hole – punching. The purlin dimensions are customizable, and it can handle steel sheets up to 5mm in thickness.

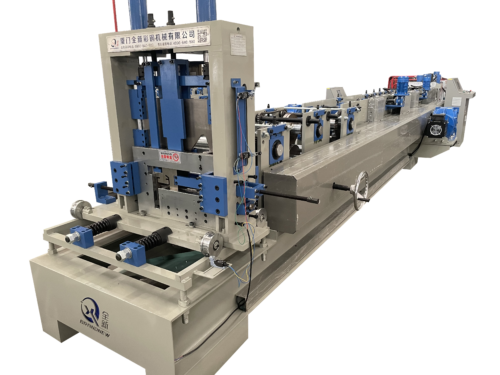

●Pre-Punch, Pre-Cut CZ Purlin Machine: Discover More

The Heavy Duty Fully Automatic BN-CZ-40040 Pre-cut CZ Purlin Roll Forming Machine features a pre-cutting and pre-punching system. Unlike standard CZ purlin machines, it doesn’t require cutter adjustments, significantly enhancing machine operation efficiency. Thanks to its unique design, it can manufacture C, Z, and U purlins with a maximum size of 350mm and handle steel sheets up to 4mm thick.

Technical Specification

| Raw Materia | Type | Galvanized Steel SheetBlack Steel Sheet |

| Thickness | 1.5-4.0mm | |

| C Purlin Size | Web x FlangexLip | 120-400/60-100/10-30 |

| Z Purlin Size | Web x Flangex Lip | 140-400/60-100/10-30 |

| Performance | Speed | 20-30m/min(30-40m/min fly cut optional) |

| C&Z Interchange | PLC Control,Fully Automatic | |

| Size Change | PLC Control,Fully Automatic | |

| Uncoiler | Type | Single Head Hydraulic |

| Capacity | 5T | |

| Main Machine | Main Roller Station | 20 |

| Main Drive | Siemens Brand Motor | |

| Transmission Type | Gearbox | |

| Punching &Cutting | Punching Location | Pre-Punch,Web/Flange |

| Punching Unit | 4 Sets | |

| Cutter Type | Mold Cutter,Fly Cut Non-Stop(Optional) |

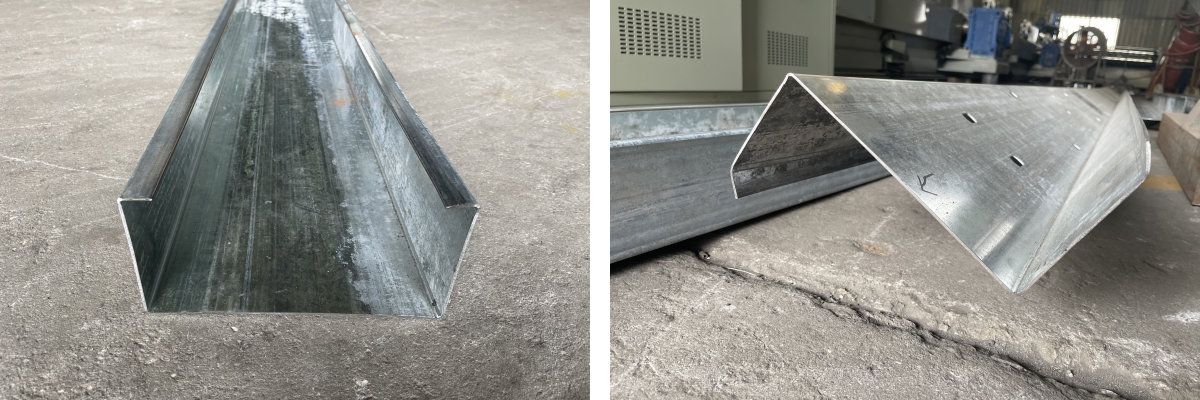

CZ purlin produced by purlin machine

Are you not sure which type of purlin making machine you need? Beenew experts can customize the purlin forming machine that suits your budget and production needs.

Video

Reviews

There are no reviews yet.