Steel Sheet Making Machine

Machine Features:

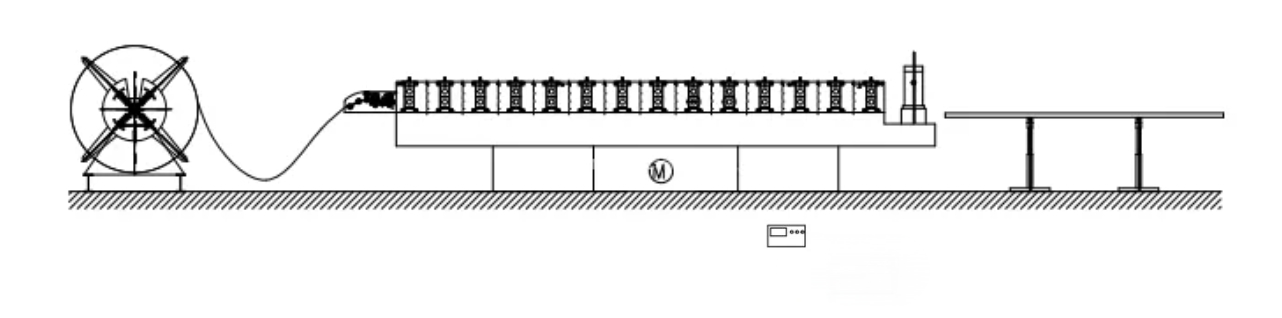

Our roofing sheets machine is composed of a decoiler, a feeding and levelling device, a pre – shear, a roll forming system, a hydraulic post – cutting mechanism, a run-out table, a hydraulic station, and a PLC (controlling system).

It can produce standard products with a yield strength reaching up to 450Mpa. The long production line ensures that the final products have an excellent profile shape. This machine is both time – saving and labor – saving, greatly enhancing production efficiency, making it highly suitable for current production requirements. Moreover, it is user – friendly, operates stably, and offers high precision.

| Machine Quick Details | |

| Model Application: Roofing | Condition: New |

| Type: Roll Forming Machine | Brand Name: Beenew |

| Applicable Materials: PPGI | Forming Speed: 20-30m/min |

| Warranty: 2 year | Place of Origin: China |

Work follow

De-coiler – Leveling device — pre-cutting – roll forming parts -Post Cutting system– Stack

MATERIAL: (Can be customized)

1) The width of the coil that can be effectively utilized: 1219mm

2) The thickness range of the coil that is appropriate: 0.4-0.5mm

3) The raw materials that are suitable for use: color steel sheet

4) The yield strength possessed by the raw material: 245Mpa

Main Components:

1. Hydraulic decoiler with coiler car

a. De-coiler: It is a hydraulic de-coiler.

b. Control type: Controlled by electric buttons.

c. Function: It can automatically rotate and feed the sheets into the next station.

d. Weight of the de-coiler: The de-coiler weighs 1 Ton.

e. Motor Power: The motor has a power of 3Kw, operates at 380V, and 50Hz (customization options are available).

2. Hydraulic pre-cutting system

a. Function: It is employed to cut the head and tail parts of the material.

b. Feature: It is equipped with a tail material reminder function.

3. Roll-Forming M/C:

a. Main Frame: The main frame of the machine is individually welded. After undergoing surface rot blasting, the outer wall is joined together with screws.

b. Roller Material: The roller is made of high-quality No.45 forged steel and processed through digital control techniques.

c. Roller Shafts: The shafts of the rollers are processed by a grinding machine twice to ensure the precision of the final product.

d. Roller Surface Treatment: Once precisely machined by the machine tool, the rollers have a 0.05mm-thick hard chrome plating on their surface. This effectively extends the service life of the forming rollers.

e. Shaft Diameter: The diameter of the shafts is 75mm or 95mm.

f. Number of Profile Forming Rollers: There are 18 stations of profile forming rollers.

g. Transmission and Drive: The production line is moved by a combination of chain and gear, which is powered by a motor.

h. Control System: All working operations are automatically controlled by the PLC electric cabinet.

i. Power Voltage: The suitable power voltage is 380V, 50Hz, three-phase (customization is available).

j. Working Speed: The working speed of the line (forming speed) is approximately 20m/min (excluding the cutting time).

k. Main Machine Motor Power: The power of the main machine motor is around 7.5KW.

4. Hydraulic Post Cutting

a. Cutting Mode: It adopts post cutting method, and the machine will stop during the cutting process.

b. Cutting Blade Material: The material of the cutting blade is Cr12, which has undergone quenched treatment.

c. Frame Structure: A welded frame is adopted, ensuring good rigidity.

d. Treatment of Cutting Frame: The cutting frame has been heat treated to prevent the deformation of the final product. The tolerance of the cutting length is ±2mm.

5. Hydraulic station:

a. Function: It provides the power source for the hydraulic cutter.

b. Accessories Brand: All the hydraulic accessories are either renowned Chinese brands or imported well-known brand products.

c. Oil Pump Power: The power of the oil pump in the hydraulic station is 5.5 KW.

d. Servo Motor and Drive Components: The power of the follow servo motor is 5.0KW, which is of the Inovance brand. It uses a linear guide and a ball screw for driving.

6. Profile Stack

a. Power Feature: It is un-powered.

b. Quantity: There are a total of 3 units.

c. Design Feature: Each stack has rollers on the top, which facilitates easy movement.

Reviews

There are no reviews yet.