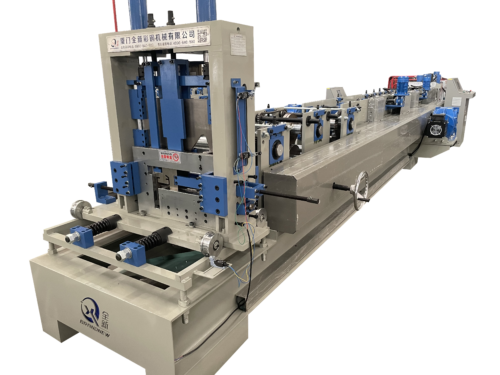

Z Purlin Machine

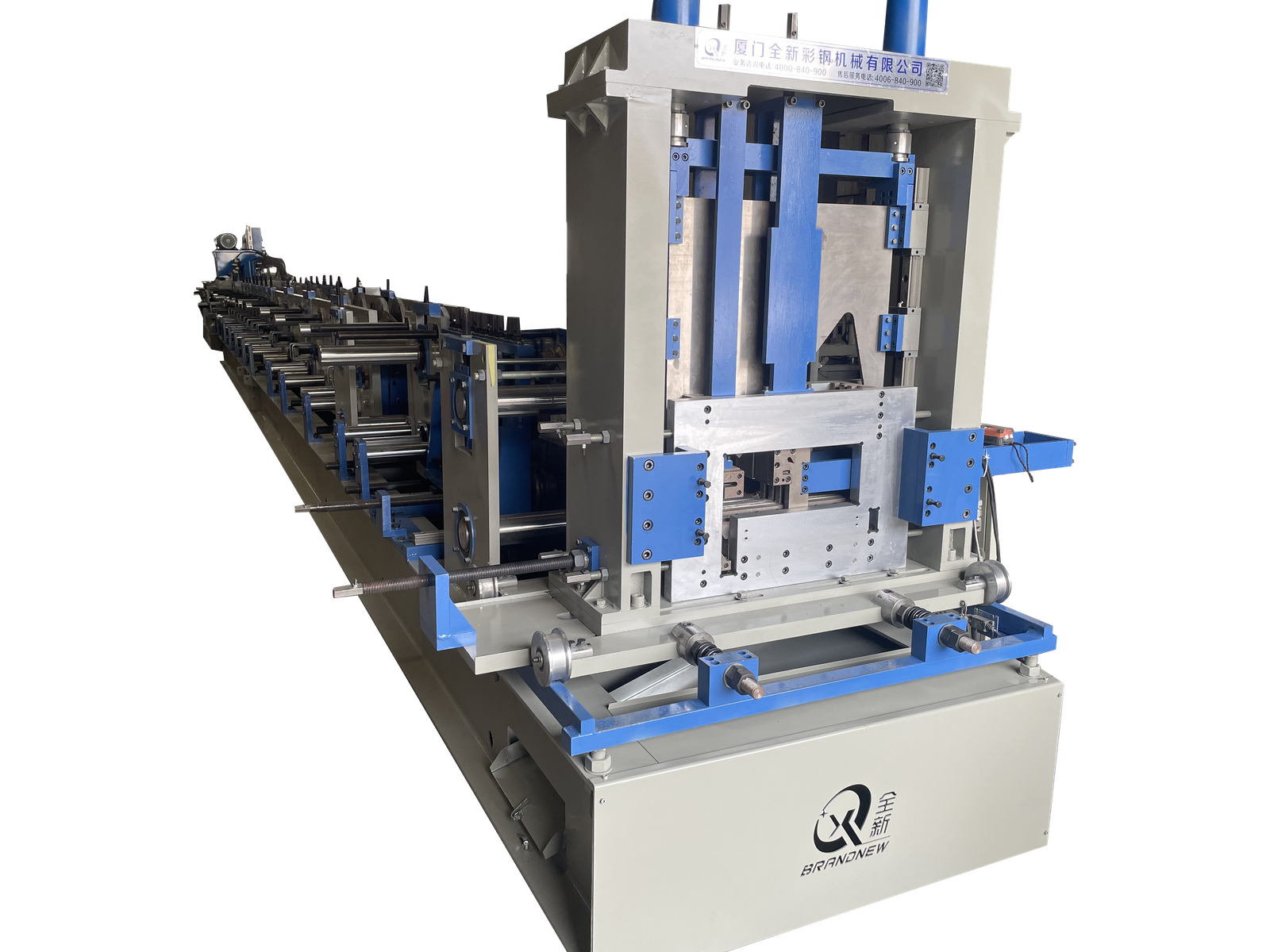

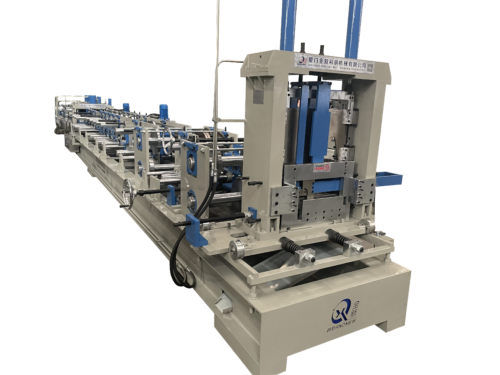

Beenew Z purlin roll forming machine produces galvanized Z-shaped steel purlins with excellent bending resistance, high straightness, and integrated online punching/cutting capabilities for efficient fabrication.

Work flow

Uncoiler – Pre-Cutting Unit – Straightening & Alignment – Roll Forming Station – Inkjet Marking – Auto Punching System – Flying Cut-off – Product rack

Machine components

Hydraulic Uncoiler

1.Expanding Type: Hydraulic Expansion

2.Decoil Method: Motorized Active Decoiling

Flattening & Guiding System

1.Flattening: Top 3 + bottom 4 solid shafts, with 4 additional pinch shafts.

2.Guiding: Adjustable-width guiding shaft and rolls for multi-size steel strips.

3.Shafts: CNC-machined; quenched & tempered; precision-turned, polished, chrome-plated.

Main Roll Forming Machine

1.Roll Stand: 20 forming stations

2.Transmission: Chain-gear combined drive

3.Base: H500 steel plate welded; shot-blasted & heat-treated

4.Rollers: Flat rollers: GCr15; angled rollers: Cr12 mold steel; CNC-machined, heat-treated, precision-turned/polished/chrome-plated (HRC 58-60)

5.Main Shaft: SAE 5140; CNC-machined; quenched & tempered; precision-turned/polished/chrome-plated

6.Motor: Servo-driven main motor

7.Size Adjustment: PLC-controlled automatic adjustment

8.Straightening Unit: 10-roller dual-axis + 4-roller axial units; eliminates curvature, bowing, sweep, or twist.

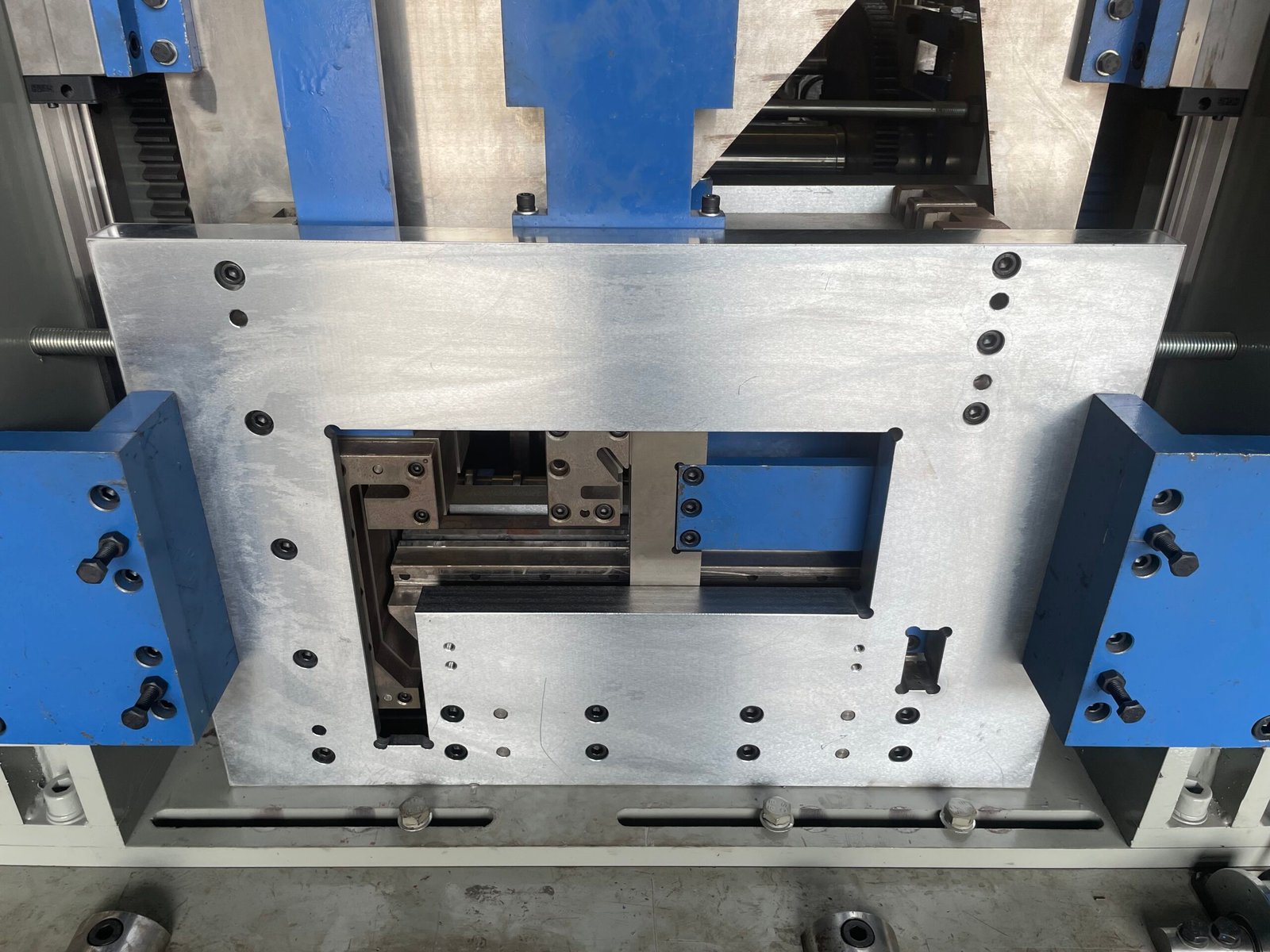

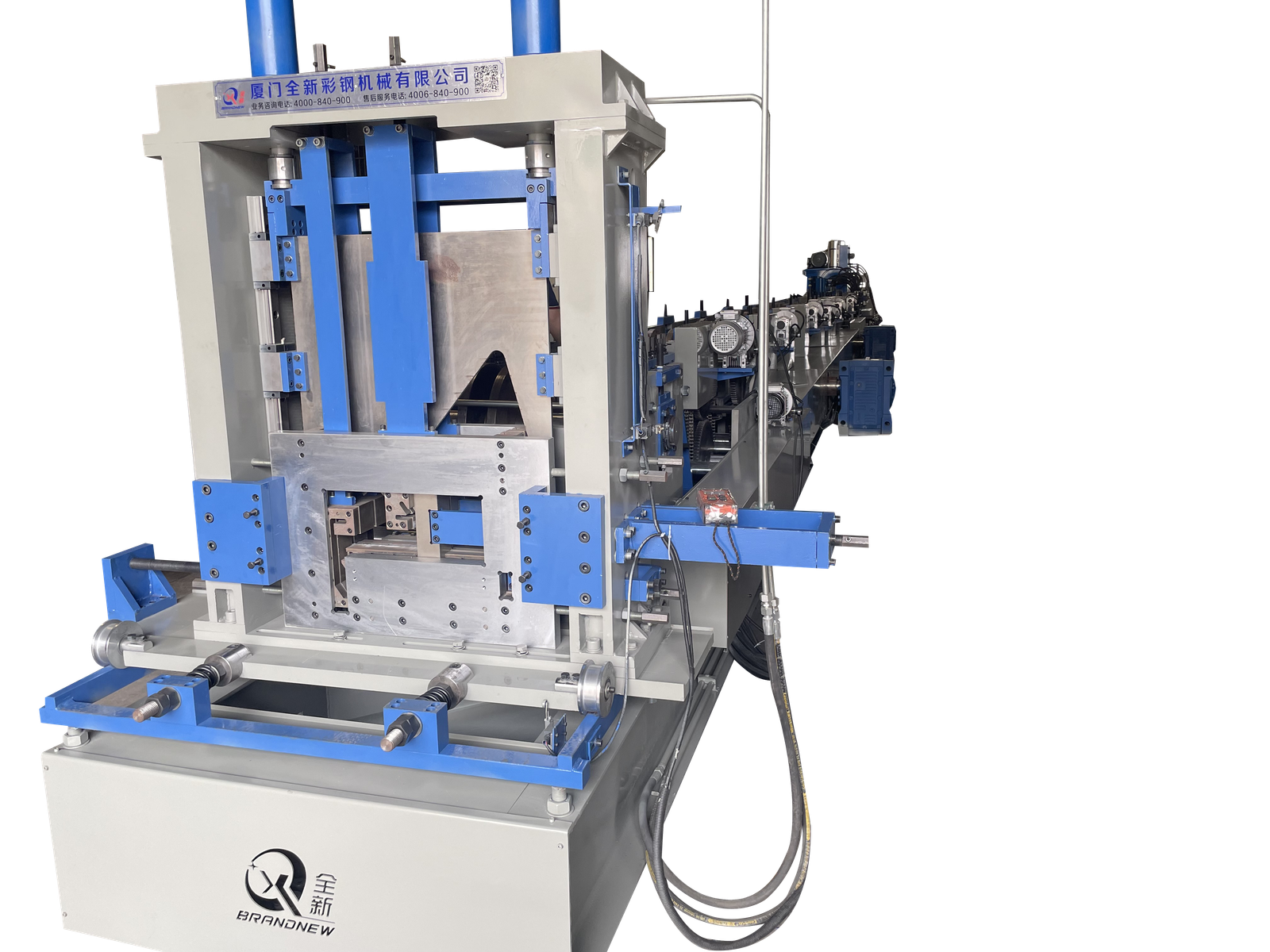

Hydraulic Punching

1.Type: Post-punch system with automated parameter setup.

2.Cylinders: 3 hydraulic punching units.

3.Dies: Customizable based on customer specifications.

Post-Cutter

1.Type: Post-cut system with automated length/quantity control.

2.Blade Material: SAE/AISI D3 tool steel, quenched.

Power Supply & Control System

1.Control Cabinet: 1 unit with emergency stop.

2.Control Handle: 1 unit for jog control during testing/production.

3.Operation Interface: HMI + physical buttons; English display.

Product rack

Type:2 sets,3m each one,free roller type

Z Purlin Size that Made by Beenew Roll Forming Machine

1.Web:140-300mm,Flange:50-80,Lip:10-20mm(CZ30030)

2.Web:140-350,Flange:50-80,Lip:10-20mm(CZ35035)

3.Web:140-400,Flange:60-80,Lip:10-30mm(CZ40040)

4.Customization: Other Z purlin roll forming machine configurations available (tailored to specifications)

Roof Z-Purlin Joints

Installation: Galvanized Z-purlins installed on the upper side along the longitudinal slope.

Beam Connection: Grade C bolts secure purlins to pre-welded, primed support plates (factory-welded to steel beams).

End Connections: Large/small ends customized for site sequence; head dimensions match joint requirements.

Adjustment: Perforation quantity increased (wall purlins included) to simplify on-site alignment.

Difference Between C Purlin and Z Purlin

1.Shape:

C Purlin: 90° angle.

Z Purlin: 60-75° angle, optimizing bending performance for sloped roofs.

2.Continuous Members:

Z purlins allow easier overlapping for seamless connections, ideal for continuous beam design.

3.Bending Performance:

Low-slope roofs: Z purlin’s section modulus > C purlin.

High-slope roofs: Z purlin’s vertical symmetry maximizes modulus utilization.

4.Mechanical Properties:

Z Purlin: Lap joints enable continuous beam calculation; preferred for high-slope roofs to align load force with section center.

C Purlin: Suitable for walls/low-slope roofs; limited to simple spans except at openings.

Our factory

Why Choose us:

– Boasting 28 years of expertise in manufacturing CZ purlin roll formers.

– Offering products with competitive prices and high – quality standards.

– Providing a 2 – year complimentary warranty.

– Ensuring a rapid response in after – sales service.

– Capable of automatically adjusting web size from 100mm to 300mm within 5 minutes.

– Open to customization according to clients’ specific needs.

– Featuring user – friendly operation and straightforward maintenance.

– Having self – developed post cutters, where a single blade can cut all sizes of final products.

Reviews

There are no reviews yet.